Accurate measurement of trace elements in solid materials plays a vital role across a range of disciplines—from uncovering material origins and tracking chemical processes to detecting contamination and maintaining strict process control.

Many industries depend on high-sensitivity analyses to ensure product performance and to protect consumer health and safety. In fields like metallurgy and materials science, high-purity metals often exceed 99.99 % purity, meaning trace impurities must be measured at levels below 100 parts per million (ppm).

Similarly, geologists and earth scientists rely on ultra-sensitive detection, particularly for rare earth elements (REEs), to better understand complex geological processes and events.

Despite the demand for high-sensitivity measurement tools, achieving such low detection limits can be challenging and time-consuming.

Techniques that offer acceptable sensitivity usually come with one or more hurdles:

- Intricate sample preparation processes

- Complicated calibration procedures

- Costly, complex packages of multiple instruments

For instance, methods like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Optical Emission Spectroscopy (ICP-OES) require samples in liquid form, which means precise digestion and dilution steps are essential. These plasma-based techniques also face issues like spectral interferences and matrix effects, making matrix-matched standards critical for accurate calibration.

To analyze solid samples at low detection limits, ICP-MS must be paired with a compatible Laser Ablation (LA) system. However, setting up an efficient workflow with LA-ICP-MS is no easy task. The combined system's complexity and substantial footprint make it best suited for use in a dedicated laboratory setting.

The Solution

Massbox presents a revolutionary solution for trace element quantification, enhancing analytical capabilities across industries reliant on precise chemical analysis.

Utilizing Laser Ablation Laser Ionization Time of Flight Mass Spectrometry (LALI-TOF-MS), Massbox enables comprehensive and rapid characterization of major, minor, and trace elements in diverse solid materials.

This innovative approach simplifies the analytical process by removing the need for extensive sample preparation.

Accurate quantification of trace elements empowers users to gain deeper insights into chemical processes, identify contamination sources, investigate trace origins, and uphold stringent quality control standards.

Additionally, this approach holds significant potential for industries including advanced manufacturing, resource extraction, and materials science, where precise measurement of trace elements is critical for advancing innovation, research, and product development.

LALI-TOF-MS (Massbox)

Engineered to address prevalent challenges in traditional analytical techniques, Massbox's LALI-TOF-MS technology offers rapid and high-sensitivity quantification across a broad spectrum of elements.

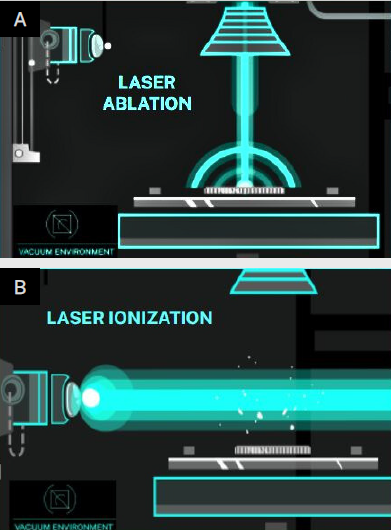

By using two lasers, the LALI ionization source effectively ablates material from solid samples and ionizes neutral particles present in the ablated material. The laser ablation process facilitates direct analysis of solid materials, removing the complexities associated with liquid sample introduction methods.

The ionization laser targets neutral particles generated by ablation, providing a more accurate representation of the constituents of the sample compared to plasma-generated ions. This targeted methodology enables automatic elemental verification and reduces sample matrix effects, contributing to the general stability of the analytical process.

After ionization, the Time of Flight (TOF) mass analyzer produces a complete mass spectrum at each laser spot, enabling detailed elemental analysis and providing information on the sample's composition.

Figure 1. A) Ablation laser fires perpendicular to the sample's surface. The laser spot size is adjustable from 5-150 microns; B) Secondary laser performs multiphoton ionization of neutral particles created by the ablation process; C) Ions are separated by Time-of-Flight mass spectrometry and detected with a multichannel plate (MCP). Image Credit: Exum Instruments

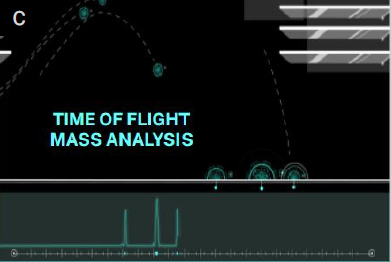

Figure 2. Detection limits for Massbox, LA-ICP- MS (Laser Ablation Inductively Coupled Plasma Mass Spectrometry), XRF (X-ray Fluorescence), and LIBS (Laser Induced Breakdown Spectroscopy). Each element is colored by its respective limit of detection. Darker colors represent lower detection limits. Image Credit: Exum Instruments

Quantifying Trace Elements

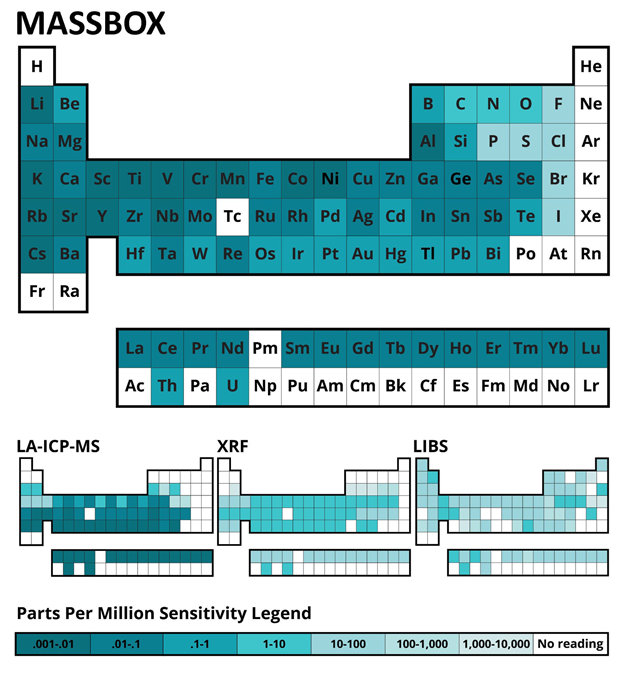

This study highlights the Massbox’s capability to detect and accurately quantify major, minor, and trace elements within a single analytical session. Using USGS black glass reference materials as test samples (Figure 3), GSE 1G was treated as an unknown and its elemental composition quantified through single-point calibration based on known values from GSE 2G.

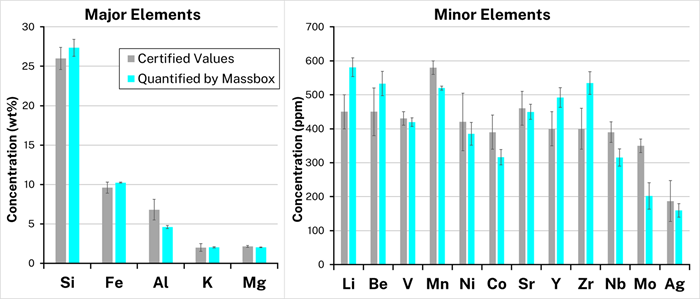

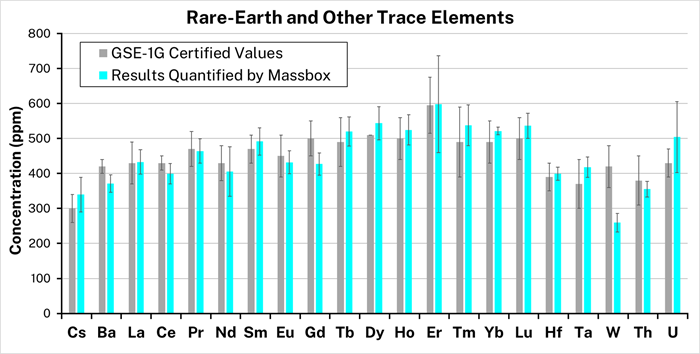

The findings, shown in Figures 4 and 5, demonstrated average accuracies of 10 % for major elements and 9 % for trace elements.

The results span a broad mass range, from light elements like lithium (Li) and beryllium (Be) to heavier elements such as tungsten (W) and uranium (U). Few analytical techniques can achieve such simultaneous sensitivity across low- and high-mass elements.

Figure 3 features a macrocamera image of the two test samples. For every analytical session, the Massbox’s camera captures the sample tray, allowing users to visually locate and define regions for analysis. On each sample, three raster areas (800 × 800 micrometers) using a 40-micron ablation laser spot were examined.

The results in Figures 4 and 5 reflect the average values from these areas, with error bars representing the standard deviations, underscoring the consistency and reliability of the measurements.

Detection Capabilities

Figure 2 presents color-contoured periodic tables comparing the Massbox’s detection limits to those of other commonly used techniques for solid sample analysis:

- LA-ICP-MS

- X-ray Fluorescence (XRF)

- Laser Induced Breakdown Spectroscopy (LIBS)

For the Massbox, most elements show detection limits in the high parts-per-billion (ppb) range. When compared to XRF and LIBS, the Massbox achieves detection limits roughly three orders of magnitude lower, making it a strong fit for high-precision quality control applications.

Thanks to its unique ionization source—Laser Ablation Laser Ionization (LALI)—and vacuum-based analysis, the Massbox can consistently detect and quantify low-mass elements like lithium, carbon, oxygen, and nitrogen. These elements are notoriously difficult to measure accurately with many other solid-sample techniques.

Figure 3. Image of GSE-1G and GSE-2G samples. The image was captured by Massbox’s macrocamera. From this image, the user chooses points, lines, or areas to analyze on the sample. The samples were placed on a typical sample holder, which required only a few min of sample preparation. Massbox can analyze an area up to 83 mm by 83 mm in each analytical session. Image Credit: Exum Instruments

Results

Figure 4 displays results for major elements (reported in weight %) and minor elements (in ppm), while Figure 5 presents data on rare-earth and other trace elements (also in ppm). All elements were detected and quantified in a single analytical session, highlighting Massbox’s broad dynamic range.

Each graph compares Massbox’s measurements (shown in blue) to the certified reference values (in gray). Massbox achieved an average accuracy of 10 % for major elements and 9 % for trace elements, closely aligning with known values.

One of the key advantages of Massbox is its ability to analyze solid samples directly, eliminating the need for extensive sample preparation. In this example, the entire process—from sample prep through analysis and data processing—took approximately 45 minutes.

Figure 4. Comparison of Massbox’s results quantified across three raster areas (blue) compared to the GSE 1G certified results (gray), demonstrating 10% average accuracy. Major elements, in wt%, are on the left and minor elements (in ppm) are on the right. For the Massbox’s results, error bars depict the standard deviation from triplicate raster areas. On the certified values, the error bars show a confidence interval for 95% uncertainty. Image Credit: Exum Instruments

Figure 5. Comparison of Massbox’s results quantified across three raster areas (blue) compared to the GSE 1G certified results (gray), demonstrating 9% average accuracy. The composition of rare-earth and other trace elements is presented in ppm. On Massbox’s results, error bars depict the standard deviation from triplicate raster areas. On the certified values, the error bars show a confidence interval for 95% uncertainty. Image Credit: Exum Instruments

Conclusions

Massbox represents a significant advancement in trace element quantification, addressing the critical need for high-sensitivity chemical analysis across various industries.

With its Laser Ablation Laser Ionization Time-of-Flight Mass Spectrometry (LALI-TOF-MS) technology, Massbox offers rapid and comprehensive characterization of trace elements within diverse materials, streamlining the analytical process with exceptional operational efficiency.

Its versatility extends to industries such as manufacturing, energy, and materials science, enabling researchers and engineers to explore chemical processes more deeply, trace material origins, identify contamination sources, and uphold rigorous quality control standards.

This study demonstrates Massbox’s ability to reliably quantify trace elements from lithium (Li) to uranium (U) at ppm-level sensitivities, achieving high accuracy when compared to certified reference values.

In addition to delivering accurate compositional analysis across the full periodic table, from lithium to uranium, the Massbox’s LALI technique offers several unique capabilities. Each ablation laser spot produces a complete mass spectrum, enabling users to generate both elemental maps and depth profiles.

Massbox can scan areas up to 83 mm by 83 mm, with spatial resolution determined by the ablation laser’s adjustable spot size, which ranges from 5 to 200 microns.

Elemental mapping reveals the spatial distribution of selected elements across the sample surface. For depth profiling, the same area can be analyzed repeatedly with raster patterns, showing how element distributions shift layer by layer. Depending on the material, each raster pass typically removes hundreds of nanometers.

Massbox also supports depth profiling with a single laser spot. By adjusting the material type and laser power settings, users can remove tens of nanometers per laser shot, which translates to about 1 micron of material ablated per second.

By combining these advanced capabilities in a compact desktop system, the Massbox provides a highly versatile tool for material analysis at any stage of the product lifecycle.

Image Credit: Exum Instruments

This information has been sourced, reviewed and adapted from materials provided by Exum Instruments.

For more information on this source, please visit Exum Instruments.