Spectro Scientific's FerroCheck 2000 is a portable magnetometer that measures the total ferrous content of in-service lubricating oils with accuracy and convenience.

Samples are analyzed in less than 30 seconds, making it quick and simple to use. To measure the ferrous content in parts per million (ppm) by weight, small sample volumes are required, as little as 1.5 ml of oil or 0.75 ml of grease. The total ferrous content of both large abnormal wear particles and small particles from normal machine wear is measured by the FerroCheck.

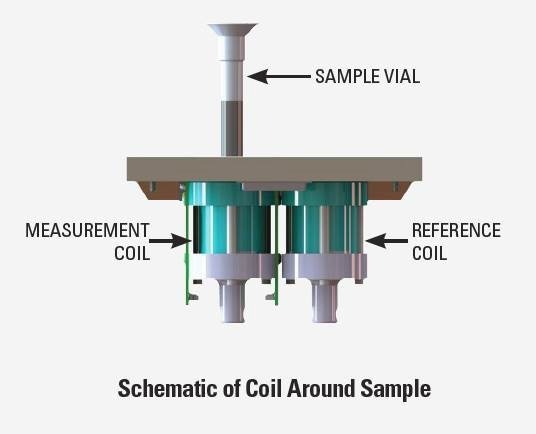

Principle of Operation

Two precisely rounded coils produce magnetic fields when powered from the FerroCheck 2000's core. Ferrous particles, such as iron, nickel, and cobalt, interact with the magnetic field when a tiny amount of in-service oil is inserted into one of the coils, causing current changes in the coils. The amount of ferrous particles in the oil, measured in parts per million (ppm) of weight, determines how much the current changes.

The oil or grease sample vial is made with an optimized position within the measurement coil in mind. The coils are electrically balanced automatically prior to the measurement, eliminating the influence of variations in the surrounding temperature on the measurement. For a big field service team performing on-site oil and grease analysis, the outcome is a repeatable and stable measurement independent of the operator and ambient temperature.

Image Credit: AMETEK Spectro Scientific

Key Features

Measure Total Ferrous Content in Part Per Million by Weight

- Measures all ferrous materials, including big abnormal wear particles and typical machine wear.

Accurate and Repeatable

- Validation standard included

- Wide range of measurement

- Low limit of detection

- Highly repeatable – 3% of reading

Easy to Use

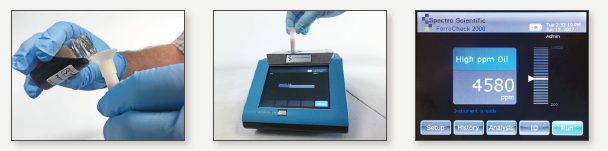

Measuring Oil

Image Credit: AMETEK Spectro Scientific

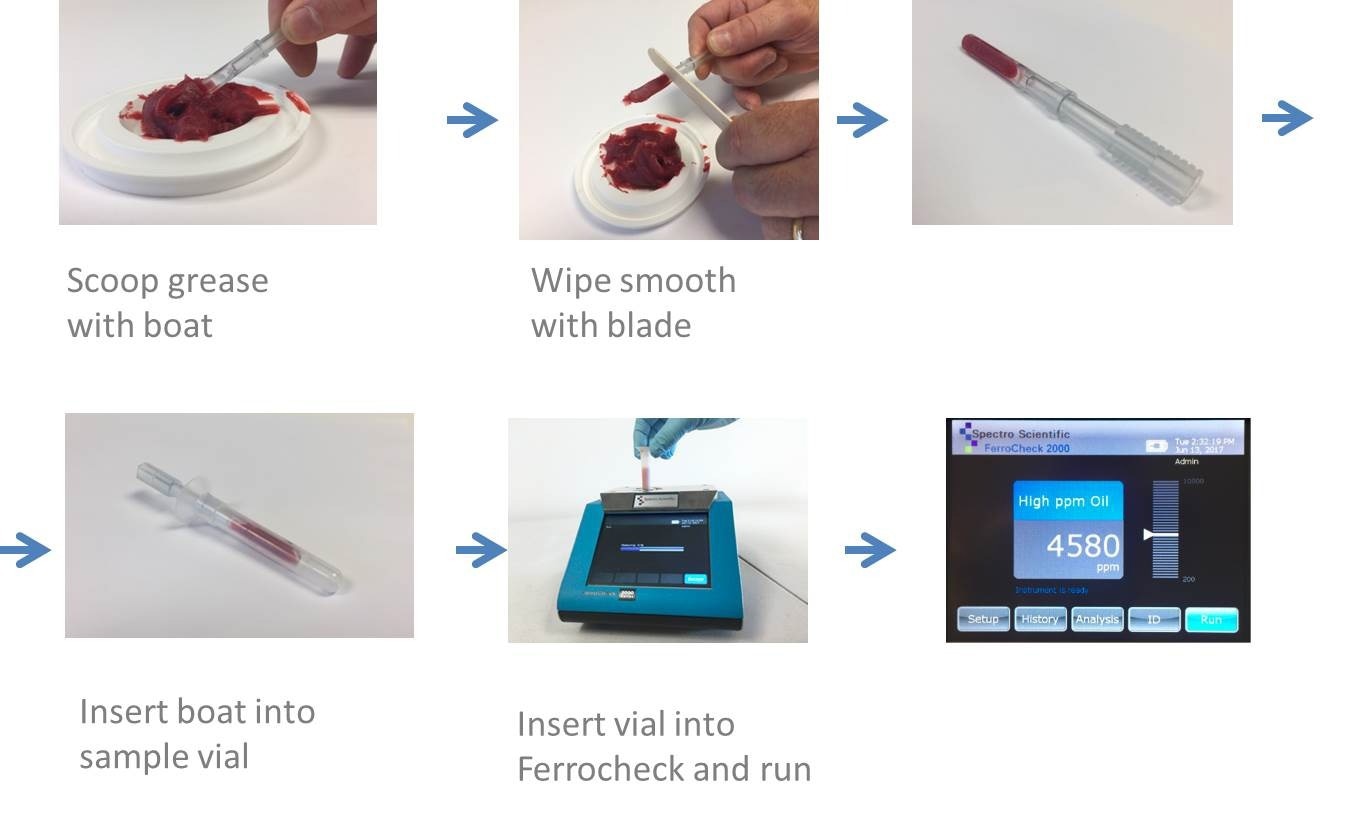

Measuring Grease

Image Credit: AMETEK Spectro Scientific

- Results in 30 seconds

- Solvent-free operation and no sample preparation

- Requires less than 2 ml of sample to test

Portable, Battery-Powered Design

Lightweight and easily fits into a toolbox or carrying bag, this device can operate for over four hours before needing a recharge. For continuous use, simply plug the unit in.

Expanded I/O Capability

Automated data archiving, csv file exporting, or AMS Oilview software interface.

ASTM Compliance

ASTM method D8120 "Standard Test Method for Ferrous Debris Quantification."

Field or Laboratory Use

- Results that are precise, consistent, and stable across a broad temperature range, intended for use in both laboratories and the field

- Rechargeable battery

Product Information

Source: AMETEK Spectro Scientific

| PN |

Ferrocheck 2000 |

Ferrocheck 2100 |

| Applications |

Lubricant oil |

Lubricant oil and grease |

| Output |

Total Ferrous, parts per million by weight |

| Methodology |

ASTM D8120 |

Standard Calibrated

Ranges |

0-2000 ppm,

2000-10,000 ppm |

0-2000 ppm and 2000-10,000 ppm for oil

0-2000 ppm, 2000 ppm-15% for grease |

| Test Time |

< 30 s |

| Limit Of Detection |

3 ppm |

| Repeatability |

3% RSD |

| Calibration |

Ferrous standards provided |

Instruments

Source: AMETEK Spectro Scientific

| Part numbers |

Instruments |

| 800-00071 |

FerroCheck 2000 Ferrous Monitor for oil |

| 800-00069 |

FerroCheck 2000 standard accessories kit. Includes instrument carrying case, dust cover,1000 sample vials, 200 vial stoppers, and oil validation standards. |

| 800-00081 |

FerroCheck 2100 Ferrous Monitor for oil and grease |

| 800-00082 |

FerroCheck 2100 standard accessories kit. Includes instrument carrying case, dust cover, 1000 sample vials, 300 grease boats and blades, 200 vial stoppers,and oil and grease validation standards. |

Consumables

Image Credit: AMETEK Spectro Scientific

Source: AMETEK Spectro Scientific

| Part numbers |

Description |

| 800-00070 |

FerroCheck 2000 consumables kit (500 Samples).

Includes 500 sample vials,100 vial stoppers, and validation standards. |

| 800-00075 |

FerroCheck 2100 consumables kit (500 Samples).

Includes 500 sample vials,100 vial stoppers,150 grease boats and blades, and validation standards. |

| 600-00033 |

FerroCheck sample vials, qty 100 |

| 600-00031 |

Grease sample boats and blades, qty 50 each |

| 600-00032 |

Grease boat, blade and vial kit, qty of 50 each

|

| 600-00074 |

FerroCheck sample vial stoppers, qty 100 each |

| 600-00113 |

100 ppm verification fluid for FerroCheck (oil) |

| 600-00114 |

5000 ppm verification fluid for FerroCheck (oil) |

| 600-00124 |

Verification standard for grease, high range |

| 600-00125 |

Verification standard for grease, low range |

Combination Kits

For various applications, FerroCheck 2000 works well as a companion piece when combined with other portable oil analysis instruments. Here are some instances:

Kinematic Viscosity@ 40C Total Ferrous Content in PPM. Image Credit: AMETEK Spectro Scientific

Basic Oil Analysis Kit: The easiest way to ensure that oil is in good condition and that machine wear is within alarm limits is to quickly check the viscosity and ferrous particle concentration in the field. Field service professionals can perform basic oil analysis with the MiniVisc 3050 viscometer and the FerroCheck 2000 Series total ferrous particle measurement.

Total Ferrous Content in PPM Oxidation Tan Water Kinematic Viscosity @ 40 C. Image Credit: AMETEK Spectro Scientific

MiniLab 33 (FluidScan, Viscometer, and FerroCheck Combo): TrivectorTM MiniLab setup that measures kinematic viscosity at 40 ºC, liquid contamination (water), ferrous content for abnormal wear, and oil condition (oxidation, TAN) using the Fluidscan InfraRed Spectrometer. Small to medium-sized industrial or power plants wishing to launch an on-site oil analysis program will find it ideal.