Sep 19 2016

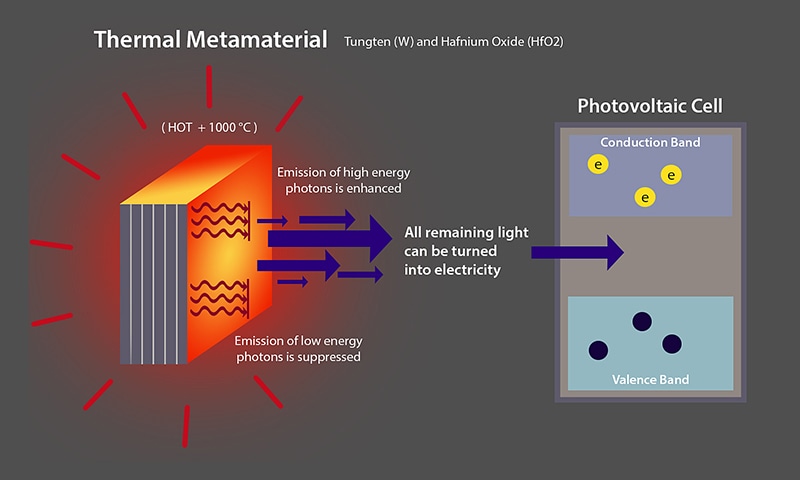

The thermal metamaterial represented in this graphic could make possible more efficient thermophotovoltaic devices that generate electricity from thermal radiation. Such a technology might be adapted to industrial pipes in factories and power plants, as well as on car engines and automotive exhaust systems, to recapture a portion of the energy wasted as heat. (Purdue University image/ Gabriela Sincich and Matthew Bollinger)

The thermal metamaterial represented in this graphic could make possible more efficient thermophotovoltaic devices that generate electricity from thermal radiation. Such a technology might be adapted to industrial pipes in factories and power plants, as well as on car engines and automotive exhaust systems, to recapture a portion of the energy wasted as heat. (Purdue University image/ Gabriela Sincich and Matthew Bollinger)

A thermal metamaterial has been used by a global research team to monitor the emission of radiation at high temperatures. This move will help to develop devices that are capable of harvesting waste heat from factories and power plants in an efficient manner.

Approximately 50 to 60% of the energy produced in coal and oil-based power plants is wasted as heat. However, thermophotovoltaic devices that provide electricity from thermal radiation could be modified to industrial pipes in power plants and factories, as well as on automotive exhaust systems and car engines in order to recapture much of the wasted energy.

In recent findings, researchers have illustrated how to limit the emission of thermal radiation to a portion of the spectrum often required for thermophotovoltaic technology.

These devices require spectrally tailored thermal emission at high temperatures, and our research shows that intrinsic material properties can be controlled so that a very hot object glows only in certain colors. The main idea is to start controlling thermal emission at record high temperatures in ways that haven't been done before.

Zubin Jacob, Assistant Professor, Purdue University

The thermal material, comprising of nanoscale layers of hafnium oxide and tungsten, was used to suppress the emission of one part of the spectrum while improving emission in another.

Metamaterials are complex media available with patterns, features, or elements such as extremely small nanoantennas that enable unprecedented control of light. Metamaterials were under development for almost 15 years, and they owe their unique abilities to both precision design and manufacture on the scale of nanometers.

"They have been used mainly to manipulate coherent light, as in a laser, but the ability to manipulate infrared thermal radiation at 1,000 C opens up new areas of research," Jacob said. "The technique we used to achieve this thermal suppression and enhancement is fundamentally different from existing thermal engineering approaches and harnesses a phenomenon called topological transitions."

The findings were presented in a research paper published in the journal Nature Communications. The work was carried out by researchers at Purdue, the Hamburg University of Technology in Germany; University of Alberta in Canada; and Helmholtz-Zentrum Geesthacht Centre for Materials and Coastal Research in Germany. The co-lead authors were Hamburg University of Technology postdoctoral researcher Pavel Dyachenko and University of Alberta doctoral student Sean Molesky.

The research symbolizes the first time the approach was used for thermal emission in high-temperature metamaterials, also known as refractory metamaterials.

"My student, Sean Molesky, theoretically predicted it in 2012, and it has taken about four years and some exceptional materials engineering from our collaborators to perform the high-temperature experiments and demonstrate the thermal metamaterial," Jacob said.

The fundamental operating principle of a photovoltaic cell is that a semiconducting material is illuminated with light, resulting in the movement of electrons from one energy level to another. Electrons present in the semiconductor occupy an area of energy known as the valence band while the material exists in the dark.

The shining of light on the material results in the electrons absorbing energy, elevating them into an area of higher energy known as the conduction band. Holes are formed in the valance band as the electrons travel towards the conduction band. The region existing between both the bands where electrons are not present is called the band gap.

If you have energy below the band gap, that is generally wasted. So what you want to do for high-efficiency thermal energy conversion is suppress the thermal emission below the band gap and enhance it above the band gap, and this is what we have done. We have used the topological transition in a way that was not done before for thermal enhancement and suppression, enhancing the high-energy part of the emission spectrum and suppressing the low-energy thermal photons. This allows us to emit light only within the energy spectrum above the band gap.

Zubin Jacob, Assistant Professor, Purdue University

The authors of the paper are Jacob; Hamburg University of Technology researchers Alexander Yu Petrov, Slawa Lang, Manfred Eich, T. Krekeler and M. Ritter; and senior research scientist Michael Störmer from the Helmholtz-Zentrum Geesthacht Centre for Materials and Coastal Research.

Future work will focus on how to transform heat radiation from a thermal metamaterial to electron-hole pairs in a semiconducting material, a vital step in developing the technology. The thermophotovoltaic technology could also be readily available for commercialization within the next seven years, Jacob stated.

A graphic explaining the high-temperature thermal metamaterial is available online.

The graphic shows how thermal radiation is monitored using the shape of the surfaces: the metamaterial improves thermal radiation in the “ellipsoidal regime” at left, but suppresses the thermal radiation in the “hyperboloidal regime” at right.

The work received financial aid from the German Research Foundation, National Science and Engineering Research Council of Canada, Alberta Innovates Technology Futures, and the Helmholtz-Alberta Initiative.