Typically, when level sensors need to be autoclaved for sterilization, the sensors require items such as housings to be disassembled prior to the autoclave process so they will not get ruined in the autoclave process. The removal of these items is time consuming and not always an easy task.

Drexelbrook, a world leader in level measurement technology, have developed the Universal IV level sensor, an RF admittance based sensor especially suited for easy intrinsically safe level measurement.

To provide an ideal level measurement solution for pharmaceutical and biotech industries where primary level sensors need sterilization, the Universal IV sensor features Triclamp process mounting along with a quick disconnect option to wiring connections. This allows the sensor to be quickly and easily removed from the vessel by disconnecting electrical and process connections.

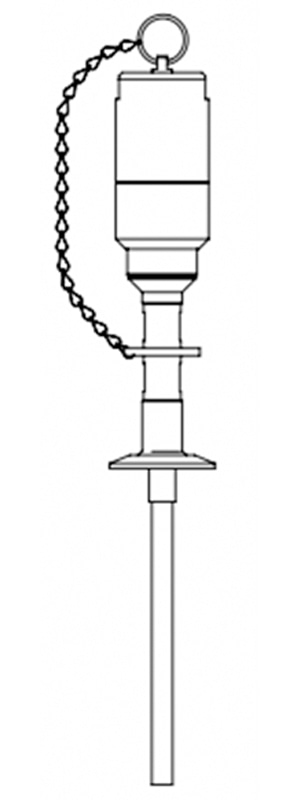

The main housing body of the Universal IV level sensor consists of a rugged 316LSS construction including a 316LSS cap with a retaining chain to prevent loss of housing. An EDPM O-ring seals and protects a 6-pin connector to ensure that any foreign material or moisture from the electrical connections are kept out during the autoclave process.

A crimped 316LSS inactive section placed below the Triclamp mounting eliminates bacteria retaining crevasses between the Teflon sensor rod and process mounting.

The Universal IV level sensor carries a 3/8 inch OD TFE Teflon sensing element that is custom made to the user defined insertion length. All process wetted parts of the Universal IV are made from TFE Teflon® and 316LSS.

In cases where the entire vessel needs to be autoclaved after a process run, the innovative design of the Universal IV level sensor enables it to survive while remaining installed in the vessel throughout the full autoclave process. As a truly unique feature the Universal IV is also ideal as a permanent installation on vessels that are continuously autoclaved as the sensor is not damaged by continuous autoclave and does therefore not need to be removed from the vessel.

The sensor temperature is rated from -65° C to +175° C (-85° F to +347° F).

Drexelbrook is an acknowledged leader in level measurement with more than 50 years of industry experience. It offers a full range of process level measurement solutions, including RF Admittance/Capacitance, TDR/GWR, Radar, Ultrasonic, Magnetostrictive, Hydrostatic, Vibration, Conductive and Float devices.