Jul 10 2018

Long established as the leading provider of sealing solutions for the aerospace industry, Trelleborg Sealing Solutions is set to unveil its latest offerings at the Farnborough International Airshow in July. These will include the unique capabilities of advanced composite solutions and Automated Fiber Placement (AFP) expertise, added to its portfolio after Trelleborg Group acquired U.S. company, Automated Dynamics.

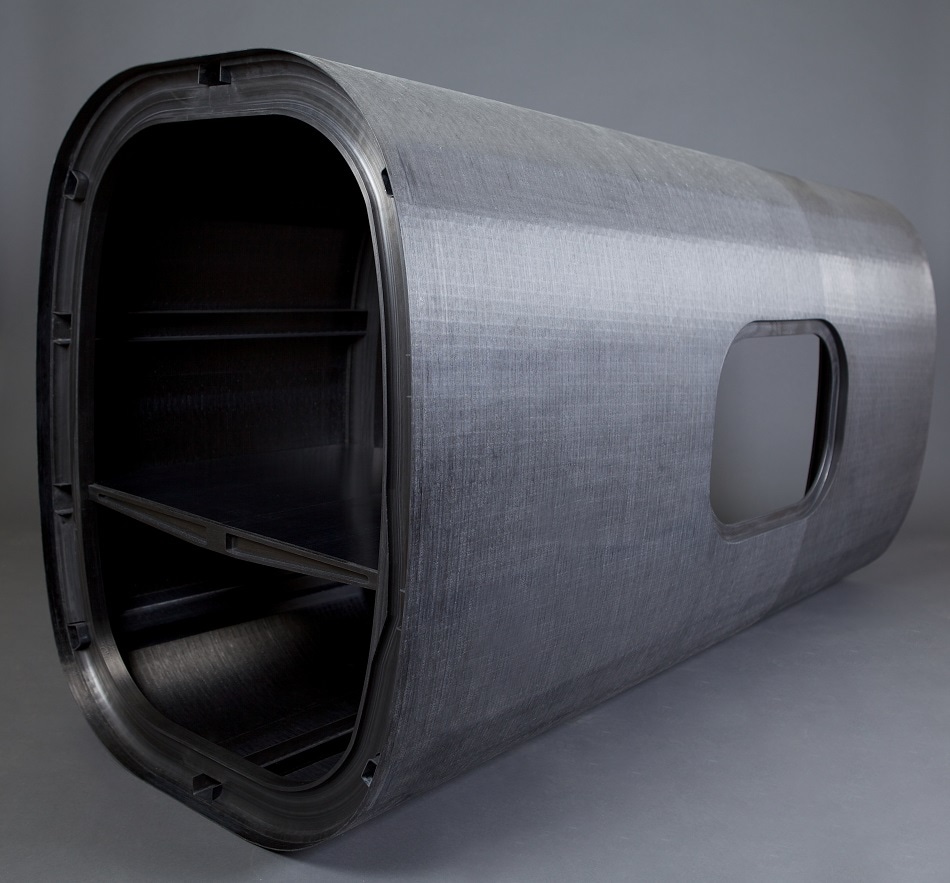

Thermoplastic composite parts will be highlighted at Farnborough International Airshow, specifically the ability to manufacture them in-place, otherwise known as in-situ manufacturing. Trelleborg Sealing Solutions will showcase a cobonded stiffened panel made via in-situ AFP.

Rob Langone, General Manager of Trelleborg Sealing Solutions in Albany in the U.S., previously Automated Dynamics, said: “We’ve been manufacturing thermoplastics for decades, focusing on continually improving the process. The stiffened panel that will be displayed at the Farnborough Airshow is just the latest example of what can be done to support the commercial aerospace industry with the use of thermoplastics.

“Historically, the aerospace industry has favored thermoset products, but we’re seeing a migration towards thermoplastic composites. This is because thermoplastic composites offer many advantages over their thermoset counterparts, including inherent flame retardancy, high degrees of impact toughness, low moisture absorption, and the ability to be stored at room temperature indefinitely.”

The thermoplastic composite process involves an AFP machine and proprietary software to gauge heat and pressure as raw materials are laid down layer-by-layer. Little time is needed to produce a fully consolidated laminate, and any post-processing steps such as autoclave curing are eliminated. As this is a true Out-of-Autoclave (OOA) process for continuous-fiber thermoplastic components, it has proved to be 30 percent more cost effective when compared with existing production methods.

The stiffened in-situ AFP composite panel displayed at Farnborough International Airshow demonstrate expertise that dates back over 30 years, representing the latest example of how the process has evolved. As the industry works to find ways to take advantage of thermoplastic composite materials, developers believe this process is on pace to become the chosen manufacturing method for the next generation of aircraft components. Commercial production of thermoplastic composite parts is now closer than ever to the mainstream.

Trelleborg Sealing Solutions will be displaying these latest innovations at the Farnborough International Airshow from July 16th – 22nd in Hall 4, Stand 41372.