Ultra-dense, large-area solid electrolyte membranes could cut solid-state battery production costs by ten.

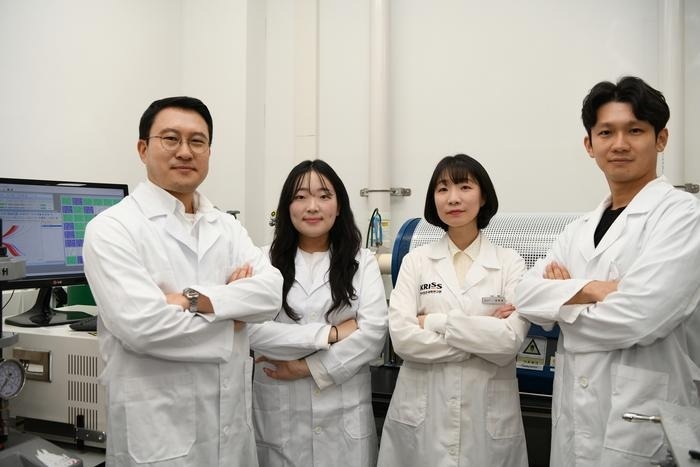

Research team behind the development of key materials technology for oxide-based solid electrolyte membranes. (From left) Dr. Baek Seung Wook, Principal Research Scientist, Emerging Material Metrology Group, KRISS; Choi Minseo, Student Researcher; Dr. Kim Hwa-Jung, Postdoctoral Researcher, KRISS; Professor Park Hyeokjun, Department of Materials Science and Engineering, Korea University. Image Credit: Korea Research Institute of Standards and Science (KRISS)

Research team behind the development of key materials technology for oxide-based solid electrolyte membranes. (From left) Dr. Baek Seung Wook, Principal Research Scientist, Emerging Material Metrology Group, KRISS; Choi Minseo, Student Researcher; Dr. Kim Hwa-Jung, Postdoctoral Researcher, KRISS; Professor Park Hyeokjun, Department of Materials Science and Engineering, Korea University. Image Credit: Korea Research Institute of Standards and Science (KRISS)

The Korea Research Institute of Standards and Science has created a critical materials technology that accelerates the commercialization of all-solid-state batteries (ASSBs) - next-generation batteries inherently designed to eliminate fire and explosion hazards. The research was published in Materials Today.

KRISS’s Emerging Material Metrology Group produced ultra-dense, large-area solid electrolyte membranes using a technique that coats solid electrolyte powders with multifunctional compounds, cutting production costs to one-tenth of traditional methods.

Lithium-ion secondary batteries, commonly used in electric vehicles (EVs) and energy storage systems (ESS), depend on flammable liquid electrolytes, which make them susceptible to fires and explosions. Once a fire starts, it is especially hard to put out.

Several incidents in recent years, including a fire at a government data center run by the National Information Resources Service (NIRS) and EV battery explosions, have highlighted the pressing need for safer lithium battery technologies.

All-solid-state batteries (ASSBs) use non-flammable solid electrolytes instead of liquid ones, fundamentally enhancing battery safety. Among these, oxide-based ASSBs have attracted considerable attention as a promising next-generation option due to their high energy density and the elimination of risks associated with toxic gas emissions that can occur in sulfide-based systems.

Oxide-based ASSBs mainly utilize garnet-type solid electrolytes as their key materials. Garnet-type electrolytes offer high ionic conductivity and excellent chemical stability; however, their inherent material properties mean that producing high-performance electrolyte membranes requires high-temperature sintering, with powders compacted at temperatures above 1,000 °C.

A key challenge in this sintering process is the evaporation of lithium, a critical component of the solid electrolyte membrane.

Lithium loss undermines the structural stability of the electrolyte, complicating large-area fabrication, and causes substantial deterioration in material quality, including lower ionic conductivity and higher interfacial resistance, due to changes in chemical composition.

To prevent lithium evaporation, traditional methods have used a large amount of a lithium-containing electrolyte material to cover the membrane during sintering.

However, this approach wastes over ten times as much mother powder as the electrolyte membrane produced, greatly increasing production costs and creating a significant obstacle to commercialization.

The research team overcame this challenge by creating a fabrication method that applies a thin coating of Li-Al-O–based (lithium-aluminum-oxide) multifunctional compounds to solid electrolyte powders.

This surface coating supplies lithium during sintering while preventing its evaporation and simultaneously strengthens interparticle bonding through a soldering-like effect, optimizing the densification of the electrolyte membrane.

Using this technique, the team achieved a record density exceeding 98.2 % without using costly mother powder, producing high-strength solid electrolyte membranes free of chemical and mechanical defects, with ionic conductivity more than twice that of conventional materials.

Additionally, the electronic conductivity of the solid electrolyte membrane was reduced by over 20 times, significantly reducing the risk of internal current leakage and improving the efficiency and safety of all-solid-state batteries.

Importantly, the research team successfully produced large-area solid electrolyte membranes measuring 16 cm2 - over ten times larger than typical laboratory-scale pellets - while achieving an outstanding yield of 99.9 %.

This achievement fully resolves long-standing materials and manufacturing challenges that have remained unsolved for more than two decades in garnet-type solid electrolyte research. By dramatically reducing production costs, our technology is expected to significantly accelerate the commercialization of oxide-based all-solid-state batteries and drive technological innovation in the energy storage systems (ESS) and electric vehicle markets.

Dr. Baek Seung-Wook, Principal Research Scientist, Emerging Material Metrology Group, Korea Research Institute of Standards and Science

“At present, Korea relies entirely on imports for garnet-type solid electrolyte pellets, which cost more than USD 550 per unit for a diameter of just 1 cm. This technological breakthrough is expected to open the door to domestic production of high-value next-generation battery materials,” noted Dr. Kim Hwa-Jung, a Postdoctoral Researcher in the Emerging Material Metrology Group at KRISS.

Journal Reference:

Kim, H.-J., et al. (2025). Revitalizing multifunctionality of Li-Al-O system enabling mother-powder-free sintering of garnet-type solid electrolytes. Materials Today. DOI: 10.1016/j.mattod.2025.11.033.