Aluminum alloys are extensively employed in a variety of industries, including aircraft, transportation, building, and high-speed rail. The performance of the welding parts and the development of the aluminum alloy weld seam will be significantly hampered if there is an oxide coating on the surface of the aluminum alloy.

Before welding aluminum alloys, the oxide coatings must be completely removed in order to optimize the welding quality. Equipment composed of aluminum alloy requires frequent repainting of the surface. A paint-stripping technique must be completed prior to spraying; however, the substrate should not be affected.

The laser-controlled cleaning method, in contrast to the typical decontamination process, cleans the material surface with concentrated laser light, which vaporizes or eliminates the material from the surface quickly. The laser-controlled cleaning of aluminum alloy surfaces has recently received study interest due to its outstanding application market and prospects. For performing laser-controlled cleaning of aluminum alloy surfaces, it is essential to comprehend the mechanisms of laser cleaning, master the rules for selection and control of laser process parameters, ensure that the paint layer or surface oxide film is removed without causing damage, and optimize the substrate performance.

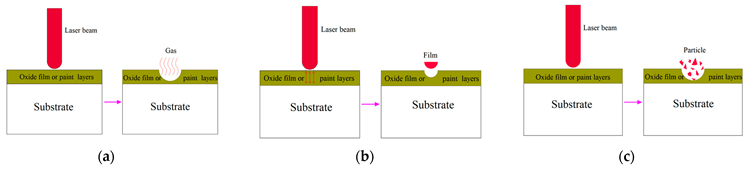

The mechanism of laser cleaning. (a) ablation gasification; (b) vibration stripping; (c) explosion stripping. Image Credit: Deng, J et al., Materials

About the Study

In this study, the authors discussed the mechanism of laser cleaning oxide deposits and paint layers off of aluminum alloy. Additionally, a thorough analysis of the effects of various processing parameters, including laser beam power, scanning speed, energy density, and others, was done.

The team illustrated that the aluminum alloy's corrosion resistance, adhesive performance, weldability, and other qualities were improved after laser cleaning. Several real-time detecting technologies for laser cleaning were also covered in this study.

The researchers reviewed the latest research on the laser-controlled cleaning of aluminum alloy surfaces, with an emphasis on the laser cleaning mechanisms, substrate performance optimization following cleaning, process parameter optimization, real-time detection of the laser cleaning, and prospects for future research directions.

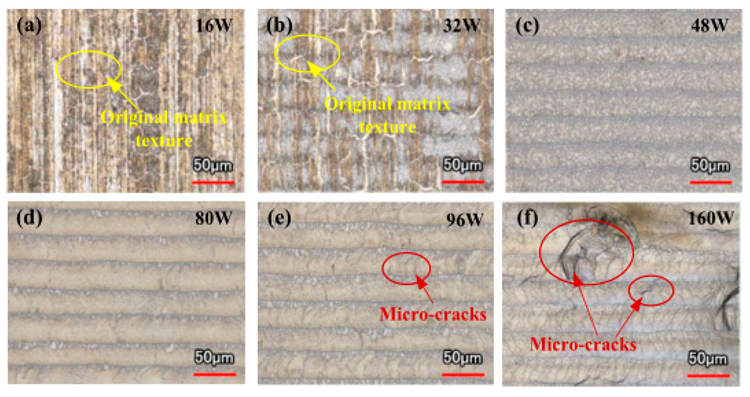

Morphology of laser-cleaned 7075 aluminum alloy with different laser powers. (a) 16 W; (b) 32 W; (c) 48 W; (d) 80 W; (e) 96 W; (f) 160 W. Image Credit: Deng, J et al., Materials

Observations

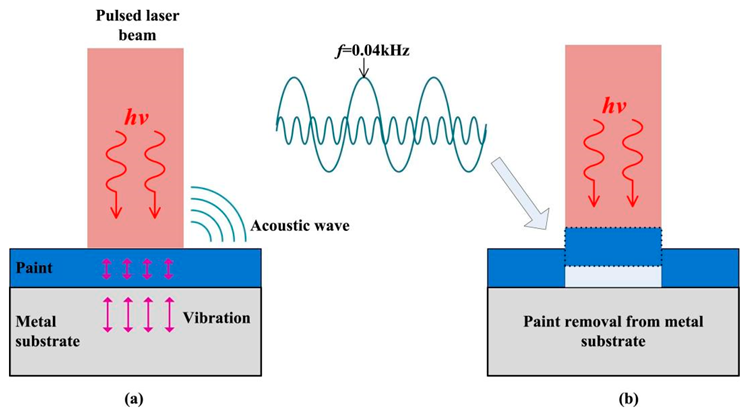

The received acoustic signal's maximum amplitude frequency was entirely above 0.04 kHz when the laser energy was below the cleaning threshold. When the cleaning threshold was reached or exceeded, the maximum amplitude frequency was always set to 0.04 kHz. The shockwaves produced by plasma explosion and air and water explosion in the strip defect raised the surface microhardness of the 7075 aluminum alloy by 5.62-8.45%.

7.1-17.5 J/cm2 was the suggested energy density range for using a laser to remove an oxide film from the surface of an aluminum alloy, and 3.2-25 J/cm2 was the recommended energy density range for doing the same for paint layers.

The three mechanisms of laser cleaning were ablation gasification, explosion stripping, and vibration stripping. When the laser energy received by the aluminum alloy's surface was greater than the material's vaporization point, the paint layer or oxide film on its surface was directly vaporized and removed. If not, the expansion and shock waves caused the paint layer or oxide film to tear away from the substrate.

The outcome of removing the paint or oxide coating from the aluminum alloy surface was highly dependent on the laser process parameters. The effect of cleaning was enhanced when the laser's power, repetition rate, energy density, and pulse width were increased or its cleaning speeds, scanning speeds, and concentrated spot area were decreased. When the laser process parameters were increased or decreased further, the substrate was ablated. Therefore, prior to laser cleaning, it was crucial to establish the damage and laser cleaning thresholds.

After laser cleaning with the right laser process settings, the corrosion resistance, adhesion performance, welding performance, bending and tensile characteristics, surface microhardness, and wear and friction performance were improved.

Schematic of the explanation for characteristic frequency. (a) The generation of the acoustic wave and (b) paint removal from the metal substrate. Image Credit: Deng, J et al., Materials

Conclusions

In conclusion, this study elucidated the mechanism of laser cleaning, the impact of various laser process parameters on the cleaning effect, substrate performance optimization, and the real-time detection technology of laser cleaning. The authors mentioned that for adopting laser-controlled and intelligent cleaning, real-time detection technologies, including laser-induced breakdown spectroscopy (LIBS), acoustic signals, and robot vision, will be useful.

They stated that even if the laser can successfully remove the paint layer and oxide film on the surface of aluminum alloy, more research on several subjects, including improving the laser cleaning system, establishing criteria for the evaluation of the laser cleaning procedure, expanding the use of the online laser cleaning detecting system, and expanding of the study of sophisticated laser cleaning technologies can be done in the future to promote the application of laser cleaning technology.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.