Monash engineers have unveiled a breakthrough catalyst that could supercharge next-generation batteries, offering more power, longer life and lower costs.

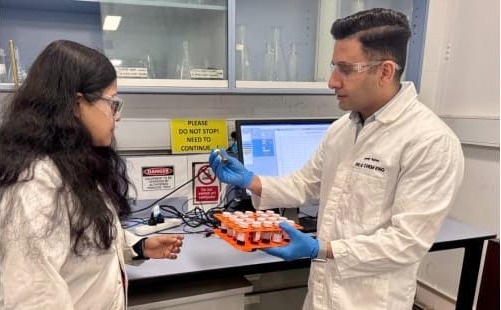

In the lab, Monash engineers are driving the next big leap in battery technology. Image Credit: Monash University

In the lab, Monash engineers are driving the next big leap in battery technology. Image Credit: Monash University

While zinc-air batteries are currently used in small devices like hearing aids, this opens the door to rechargeable, high-power applications, moving the technology closer to real-world, grid-scale and transport uses.

Using a clever heat treatment, researchers turned a 3D material into ultra-thin carbon sheets and added individual cobalt and iron atoms, creating a catalyst that makes the battery’s oxygen reactions much faster and more efficient.

Lead authors Saeed Askari and Dr Parama Banerjee, from the Department of Chemical and Biological Engineering, said it outperformed standard commercial catalysts made from expensive metals like platinum and ruthenium.

“By engineering cobalt and iron as individual atoms on a carbon framework, we achieved record-breaking performance in zinc-air batteries, showing what is possible when catalysts are designed with atomic precision,” Mr Askari said.

“Our advanced simulations revealed that the cobalt-iron atom pairs, combined with nitrogen dopants, enhance charge transfer and optimize reaction kinetics, solving one of the biggest bottlenecks for rechargeable zinc-air batteries.”

Dr Banerjee said the principles behind this design could also be applied to other clean energy technologies including fuel cells, water splitting and CO2 conversion.

“Running a rechargeable zinc-air battery continuously for more than two months is a milestone for the field. It demonstrates that this technology is ready to move beyond the laboratory and into practical applications,” Dr Banerjee said.

“These catalysts not only solve a key bottleneck for zinc-air batteries, but their design principles can be applied across the energy landscape – from fuel cells to water splitting – offering broad impact for clean energy.”