Introduction

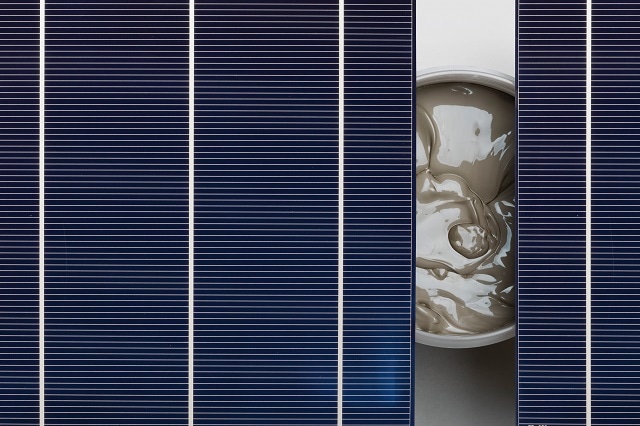

In the manufacturing of high performance, high value photovoltaic modules, the metallization of the solar cells is a critical processing step. Though solar cell manufacturers possess their own unique processing parameters and have a choice of several pastes suppliers, it is paramount that the incoming materials such as the metallization pastes meets a consistent standard. Heraeus’ involvement in the effort is to assist solar cells manufacturers in the optimization of the production of their cells.

SEMI PV54-0514 Standard

The technology developed for the solar industry evolves at much faster pace than most other traditional industries. The development occurs in almost all areas within solar cell industry and it contributes to higher solar cell efficiency and better reliability. Ag paste/metallization technology is one of the key areas that has contributed to the notable efficiency increase in the past 3 to 5 years. Qualification and testing of new Ag paste thus becomes an essential routine operation for paste suppliers as well as cell and module manufacturers.

This specification aims to provide a standard practice for Ag paste suppliers and customers to follow during the new product qualification and routine QC testing in order to accelerate the whole process as well as more consistence data generation. The standard covers, but is not limited to appearance, granularity, solids percentage and viscosity, silver layer adhesion and solder ability after firing, which are most commonly used for cell manufacturers in the incoming quality control.

The development of standard was led by the Materials Taskforce under SEMI China PV technology committee. Cell manufacturers likes Suntech (and Sunport Power) and paste suppliers like Heraeus are the key drivers in the development of this standard.

Solar cell manufacturers will benefit from incorporating this standard into their new generation of paste qualification and routine quality assurance for existing paste used in mass production. The aligned test method will enable suppliers and cell manufacturers to speak the same language on the same platform.

Why is it important to test metallization paste for solar cells?

Metallization paste is a complicated system and it has significant influence on the solar cell efficiency. The metallization paste serves a function to build up electrical contact with solar cells through firing process and transport electricity to the external devices. The proper delivery of paste to solar cell surface (normally it is screen printing) is one of the critical steps that can influence the final cell efficiency, e.g., high finger aspect ratio and less line breaks. Proper testing of metallization paste ensures the paste possess necessary properties that can be utilized in solar cell manufacturing. This standard covers most of the tests that paste suppliers and cell manufacturers are concerned with.

This will contribute to solar cell manufacturer’s effort to consistently produce high efficiency and high quality products, which in long term will be a key successfully factor for the PV industry.

Questions For Cell Manufacturers

How has this new standard helped you as a solar cell manufacturer?

We can align with paste manufacturers by following the same standard. Paste manufacturers follow this standard for all new paste development. This allows us to develop new paste quicker and at a higher cell performance. We think this silver paste standard provides an important basement for a win-win scenario between cell manufacturers and paste manufacturers.

Victor Chen - Sr. Staff Engineer, Technology Department - Wuxi Suntech Power Co., Ltd.

What impact will this have on the future development of solar cells?

When we develop future solar cells, we can use this standard to prepare paste for a trial run. This will allows us to generate a perfect paste and speed up new solar cell launch time.

Victor Chen - Sr. Staff Engineer, Technology Department - Wuxi Suntech Power Co., Ltd.

Suntech Power: How Suntech Photovoltaic Cells and Modules are Made (English Version)

Video courtesy of SunTech Power YouTube channel

Conclusion

The photovoltaics industry is a vital contributor to the current and future supply of clean energy for the world. To increase the adoption rate of solar, suppliers within this industry have been working to reduce the cost per watt throughout the supply chain. Collaborations such as the SEMI PV54-0514; the “Specification for Silver Pate, Used to Contact with N+ Diffusion Layer of Crystalline Silicon Solar Cells”, allows paste and cell manufactures to develop processes to improve cell manufacturing that helps in the reduction of cost. As seen over recent years, as the price per watt to install PV is reduced, the investment decision for PV improves due to better returns. This helps the suppliers in the PV supply chain and our environment.

To learn more, click here.

This information has been sourced, reviewed and adapted from materials provided by Chi long Chen, Global Scale Up Manager at Heraeus Photovoltaics Global Business Unit. Additional information was also provided from Heraeus Photovoltaics Global Business Unit.