| As you travel around Britain, the distinctive characteristics of villages and towns change markedly as architectural styles vary from region to region. This is partially down to local preferences and traditions and can also be seen on a global scale. However, the differences really stem from the local availability of building materials. Old buildings in Cornwall have granite walls and roof tiles made of slates, whereas in Norfolk buildings of the same age often have flint walls and roofs made of fired clay tiles. Such historic limitations in material choice have given rise to each region’s particular style, which local planning authorities like to preserve. Dictating the general design of buildings is one way to keep new developments in character. Another is to use modern materials technology for building houses that are up to the required standards, but which also have the aesthetic characteristics of the traditional buildings. Origins of Building Materials There has been a revolution in building efficiency and quality since the development of modern transport facilities. The wider range of materials and products that is available quickly and easily has led to buildings with improved insulation, ventilation and other properties. This in turn yields environmental and cost benefits through lower heating and air conditioning costs. Not all of these widely available building materials are new, though. For example, the Myceneans were using pozzolanic cement technology around 3,000 BC, and the first clay bricks probably date back even further to the Sumarians some 6,000 years ago. Terracotta roof tiles were used during the time of the Greek Empire and were introduced to the rest of Europe by the Romans. They have also been found in early East Asian archaeological deposits from the same period in China, Korea and Japan. Concrete Roofing Products Such an influx of new materials could lead to the loss of regional characteristics if buildings are constructed using the variety of available technologies. However, one modern technology can be used while retaining local style as the materials can be made to match traditional systems - cements and concrete. Today, these materials are particularly widely used for the production of roofing systems that look similar to local materials such as slates, fired clay and terracotta. Origins of Cement-Based Roofing Products Cements featured in construction in ancient times, but were not used for making roof tiles until mass production of the materials started in the 19th century. The first cement-based tiles were made in 1844 at the Kroher cement factory in Staudach, Bavaria. Until 1920 they were normally cast as square products, which were laid on the roof in a diamond pattern. In the early days, pigmented coatings were applied to the surface of the tiles, but efflorescence and poor colour durability rapidly spoiled the appearance. As a result, uncoated tiles of plain cement were preferred and quickly became popular. Extruded Concrete Roofing Tiles Over the years, concrete tiles and their production processes have evolved to give the products more aesthetic appeal. The major breakthrough came in 1919 when the first extruded tiles were made in the UK. This new technology was soon commercialised in Australia, South Africa and the rest of Europe, allowing tiles to be mass-produced instead of being virtually hand-made. The new factories could make as many as 20 million tiles each year. Improvements to Colourings, Coatings and Textures Other improvements have followed including improved colourings, coatings and surface textures. These are now making it possible for concrete roof tiles to offer the look of more traditional roofing tiles, figure 1. Modern concrete tiles typically have the appearance of clay tiles or natural slates. |

| | Figure 1. A typical interlocking concrete roofing tile. | A more impressive example of material mimicry is the concrete copy of ‘cedar shake’, a very popular traditional roofing material in the United States. Cedar shake is basically formed from wooden planks nailed together and so is highly flammable, a property not tolerated in densely populated suburban areas. Any alternative system has to be lightweight and fireproof to fit with local construction methods. Interlocking concrete tiles have been made using an extruded lightweight mortar, which contains ingredients to copy the colour and texture of cedar shake. The new material provides the additional benefits of being easier to lay and having better weather-tightness, figure 2. |

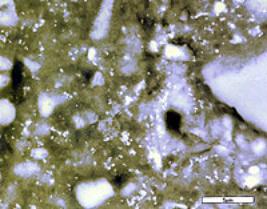

| | Figure 2. A traditional ‘cedar shake’ roof in north America made from concrete roof tiles. | Concrete Roof Tiles and Other Roofing Materials With the exception of materials such as thatch, it is now possible to imitate most traditional roofing materials with concrete. Control of the concrete’s properties and processing is vital to achieve the required surface texture and colour without compromising its functionality - that of thin interlocking plates designed to keep out water. The tiles must also conform to national standards for specific properties, including water permeability, freeze-thaw performance and strength. To achieve these performance requirements, concrete roof tiles are typically made using a mortar mix with a sand grading known as ‘sharp sand’. Iron oxide pigments are added to give the desired colours, providing the most cost effective way of making terracotta, black, brown and yellow tiles. The Use of Pigments It is important to achieve the desired colour using the minimum amount of pigment, as the pigment is usually the most expensive component in a concrete roof tile. The pigment must therefore be used efficiently, and so it is vital to ensure that it does not form agglomerates and that individual pigment particles are dispersed as widely as possible in the concrete mixture. A dispersion of iron oxide pigment particles - the high density white specs distributed throughout the mortar microstructure - is shown m figure 3. |

| | Figure 3. Microstructure of a concrete roof tile. The white specks are pigment particles distributed throughout the system. | A major enemy of bright colours is excessive efflorescence, the formation of a powdery deposit on the tiles. This arises from hydrated calcium hydroxide, which is present in hardened Portland cement. Calcium hydroxide seeps through the pores of the concrete to the surface of the tile, where it is carbonated by atmospheric carbon dioxide and forms calcium carbonate. A light dusting of calcium carbonate is not harmful, as it will be washed off by rain, leaving a pristine surface. However, a severe case of efflorescence will reduce the apparent brightness of the tiles and at worst could ruin the appearance of a roof. Reducing Efflorescence Efflorescence can occur not only in service on the roof but also during the manufacturing process or in packaging. Roof tile manufacturers therefore use a number of measures to eliminate its occurrence. It is a complex area, but most manufacturers simply aim to reduce the quantity of calcium hydroxide present in the hardened mortar, thereby reducing the risk of surface carbonation. If any efflorescence does then form, it can be easily removed in the production process by an acid washing treatment. Another widespread technique is to protect the mortar from atmospheric carbon dioxide by applying a polymeric coating. Simple coatings can be formed using clear polymers or paints, but complex multi-layer coatings can also be produced that give a surface virtually indistinguishable from locally available clay tiles. Such surface texture is another important parameter in the manufacture of concrete roof tiles - for example, there is a market in the UK for flat concrete tiles that look like weathered, hand made clay tiles. Life Expectancy and Design Criteria Irrespective of the desired appearance, the functional performance of roof tiles is essential an must be maintained throughout a tile’s life. Guarantees of 60 years or longer are often demanded, and so concrete roof tiles must keep water out for many decades while withstanding a wide rang of weather conditions. Tiles are made by extruding the sand cement mortar onto a metal support pallet that gives the tiles their underside detail. The top surface of the tile is normally smooth, the profile being defined by the shape of the pallet and the extruder itself. This design is critical to maintaining the properties of the tile. Tiles are designed to minimise total weight while retaining enough tensile strength to withstand all handling stress The design must ensure that the tiles remain totally impermeable to water, and also has to take into account the need for adequate fixing, to ensure that the roof remains in place during event of the strongest storms. Roof Tile Testing Roof tile manufacturers carry out extensive durability testing to check the tiles will survive their long guarantees. Selected sites are used for natural weathering tests, the sites being chosen for evaluating tile performance in a range of different climatic conditions. Performance criteria including freeze-thaw properties, ultraviolet resistance, resistance to acid rain and resistance to algae growth. Laboratory testing is also canted out to explore the various degradation mechanisms that may occur in different countries where the tiles are sold. Weathering Tests and Roof Tile Fixing In addition, data is taken from the weathering test sites to provide information on local weather conditions. These conditions can then be reproduced in a wind tunnel to assess the performance of a whole roof made from the tiles, figure 4. This is very important as it allows the fixing of the tiles to be evaluated. Manufacturers can ensure that extreme winds and rain will not lead to roof tiles or even whole roof sections being blown off, and so guarantee the integrity of their roofing system. |

| | Figure 4. Wind tunnel testing of roof tiles, where a variety of wind/rain conditions can be simulated. | The Future Future developments in concrete roof tiles will certainly include additional improvements to traditional appearances. Concrete tiles will be made to look even more similar to clay tiles, slates and perhaps other traditional materials. Nevertheless, concrete tiles have been around for some time now. Perhaps it is time for the development of an exciting new generation of concrete roofing materials that offer their own unique appearance as well as improved properties and roof structures. |