Interview conducted by Mychealla RiceNov 26 2018

Interview conducted by Mychealla RiceNov 26 2018Power protection is paramount in the semiconductor industry. Loss of power can be damaging for many facilities, products and processes. The semiconductor industry is very important as semiconductors serve the core building materials for important electronic products.

In this interview, Gary Aw, Business Development Manager for Semiconductor Industry, from ABB Power Conditioning talks to AZoM about their power protection solutions that prevent power outages.

The Semiconductor industry is growing rapidly, why is power protection important?

Smartphones, PCs, servers, and the Internet of Things (IoT) have been driving the demand for semiconductor chips for the past few years. This trend has driven the demand for more chips, particularly memory chips, which in turn has spurred memory players to invest quickly in new chip fabrication plants.

Companies in China have also increased their investment in chip fabrication and back-end packaging plants, in line with China’s “Made in China 2025” plan. These newly-built leading-edge technology plants cannot afford to lose time, money, and market share from production losses due to power quality events such as voltage sags and power outages. Hence why power protection is required to ensure that these investments are protected.

What type of facilities, processes, and products come under the semiconductor industry?

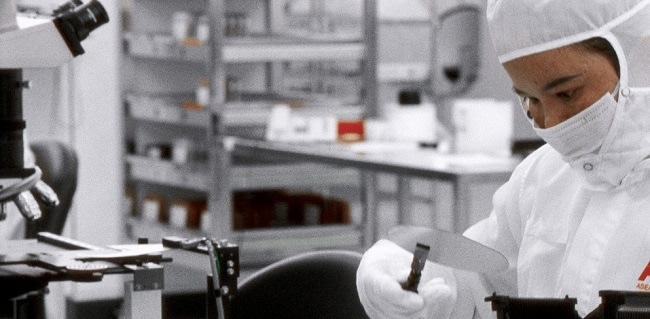

Various products are produced by the semiconductor industry that we use in our daily life, including memory, processors, sensors, power devices, optoelectronics, and displays. Facilities can be split broadly into three categories: silicon wafer plants that produce bare wafers, fabrication plants (FABs) which produce the chips, and packaging plants which package and test the chips.

Processes in a silicon plant include growing ingots, wire saws, slicing wafers, and polishing. Typical processes in a fabrication plant include lithography, etching, deposition, and chemical and mechanical polishing. In packaging plants, typical processes include dicing, bumping, molding, testing, and binning.

What would happen if a facility didn’t have a power protection solution in place?

The cost of lost production, quality, downtime, and eventually lost profit and market share can be at a massive scale for semiconductor FABs that are not sufficiently protected. Every day semiconductor facilities face a potential risk from voltage events. Often we do not read about them in the news, except when a major event occurs.

What Power Protection solutions does ABB offer that can help the semiconductor industry from interruptions which can be very damaging.

With over 20 years history in power protection equipment, ABB offers a wide coverage with low voltage and medium voltage power protection systems to protect the semiconductor industry against voltage sags and interruptions. This equipment is designed for various voltage inputs, power ranges, and autonomy protection time and can be fitted for outdoor and indoor conditions.

What type of equipment can ABB’s power protection solutions protect? What sets them apart from others on the market? What are the features and benefits of the product range ABB offers?

To cover a range of semiconductor customer needs, ABB offers three products that can be installed to protect these critical facilities against voltage sags and power interruptions.

- The PCS100 AVC-40 is an active voltage conditioner for large industrial and commercial applications. It uses no energy storage to correct sags and swells to ensure the critical facilities receive clean, premium power.

- PCS100 UPS-I is a high performance, high-efficiency industrial UPS that ensures protection from power quality events, such as deep sags or short-term outages. It enables continuous power supply to modern industrial processes.

- The PCS120 MV UPS is the next generation of medium voltage UPS intended for multi-megawatt power protection. Based on the revolutionary ZISC architecture, the PCS120 MV UPS introduces a flexible solution for higher reliability and higher efficiency in critical power facilities.

Can you tell us any case studies where ABB solutions where implemented to help protect semiconductor solutions?

ABB’s power protection solutions have been installed in many of the industry's leading semiconductor facilities around the globe, however in many cases due to the sensitivity of projects, we cannot reference company specifics. As an example, we recently received an order from a semiconductor test and assembly packing plant that builds discrete, logic, and MOSFET devices and will be using our PCS100 AVC-40 to protect their test equipment line, which has been facing productivity disruptions from voltage sags.

Tell us how the PCS100 AVC-40 is one the best solutions for plant protection?

Each semiconductor customer has different needs for their plant protection, so one solution does not fit all. However, the PCS100 AVC-40 does offer the best solution with respect to optimal footprint and cost to our end customers who suffer primarily from voltage sags.

What do ABB’s power protection solutions mean for the future of the semiconductor industry?

ABB’s power conditioning team engages continuously with our customers and develops solutions to meet their specifications and needs. We also have an exciting pipeline coming through with our next generation products, which will be launched in the near future.

Where can our readers go to find out more?

You can find more information about the PCS100 product range, case studies and videos at our ABB website here.

https://global.abb/group/en

https://new.abb.com/ups/ups-and-power-conditioning/industries/semiconductor-solutions

About Gary Aw

Gary studied a Bachelor of electrical engineering at the National University of Singapore majoring in power electronics. Gary obtained his Masters of Business Administration in Mannheim Business School in 2010.

Gary has worked as Product Manager and Business Development Manager in the semiconductor and electronics field for the over 15 years at several companies including Infineon, Broadcom, GlobalFoundries and Dow Corning. Gary is currently ABB’s power conditioning Business Development Manager for Semiconductor Industry.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.