An interview with Dr. Florian Glauche, Product Manager, Knauer

Please give me an overview of the dosing pump range that Knauer offers.

KNAUER dosing pumps are precise dual piston pumps which are designed for standalone and remote-controlled operation. We offer dosing pumps for flow rates of up to 48 l/h and pressures of up to 650 bar (at up to 300 ml/h).

Our entry-level dosing pumps feature a compact form factor and are available with and without pressure transducer for flow rates of up to 2.4 l/h at pressures of up to 300 bar. The high-end dosing pumps feature automatic pump head recognition, an LCD touchscreen, and active pulsation compensation.

They are available at flow rates ranging from 6 ml/h up to 48 l/h at pressures of up to 650 bar. For ultra-high-pressure applications of up to 1000 bar, our UHPLC system pump or a pneumatically driven pump can be used.

.jpeg)

What makes the Knauer dosing pump range so flexible?

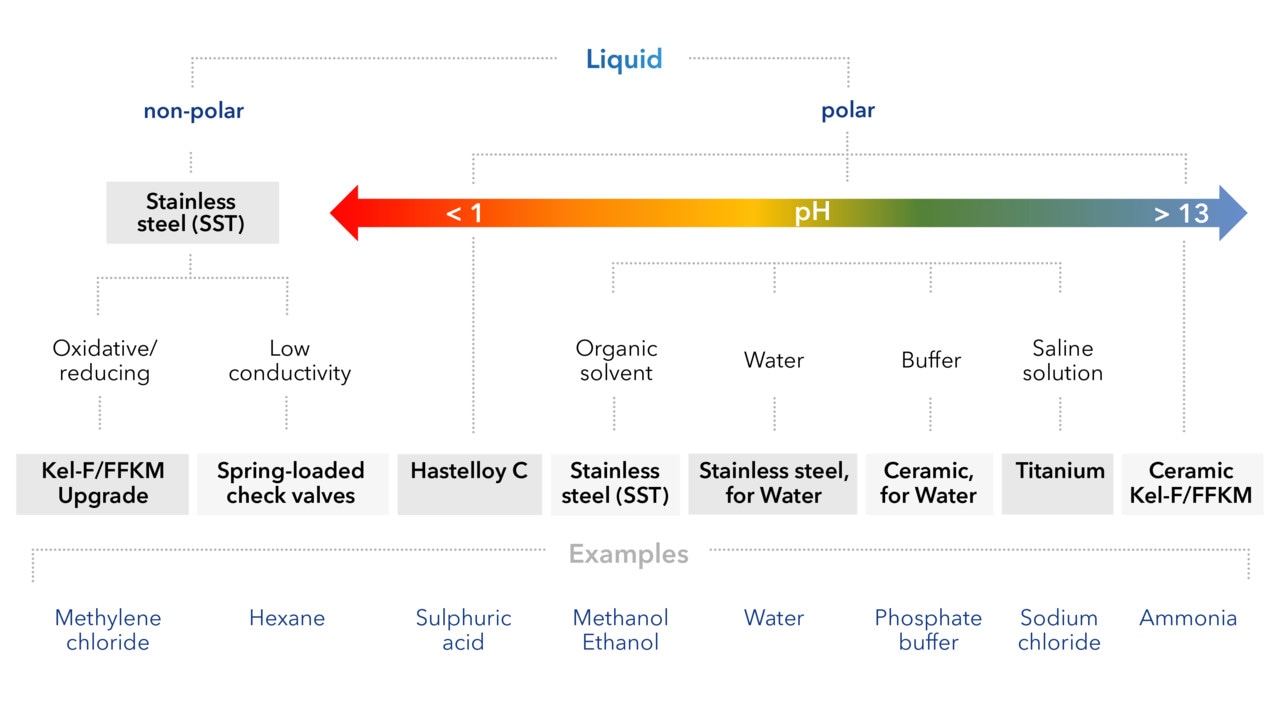

Our dosing pump line is resistant to a wide range of chemicals. The pump head can be exchanged to adapt the pump to different dosing tasks. Integration into the process or laboratory environment is easy, since the pumps can be controlled via analogue signals, the local area network, or a RS-232 interface.

Why is it important to have a compact dosing pump option? What can this pump be used for?

The small form factor is perfect for experimental setups with tight constraints on the available lab space (e.g. under a fume hood). A small housing is attractive for integration into larger laboratory devices and production environments. Even the integration of multiple compact pumps for special purpose analysers are known.

What applications can Knauer dosing pumps be used for? Are there any limitations?

KNAUER dosing pumps are applied in the chemical industry as well as in research and development. They accurately deliver solvents, aggressive substances, viscous oils, and even radioactive liquids. For high-temperature applications, we offer a special version of our BlueShadow Pump 40P, which can pump preheated liquids at up to 120°C.

Since our pumps operate with check valves, dosing of particle suspensions is a challenging task. For special requests, we offer application testing as a service. Send us your sample and we make sure that the dosing system will work flawlessly in your laboratory or at your production site.

How are the accuracy and precision maintained with fluids that are aggressive, viscous and varying extremes in temperature?

.png)

After assembly, the calibration and quality control of our pumps is performed using ethanol. For other fluids, we offer qualification of the pump at the customer’s site. Alternatively, we also offer training for customers to perform calibration and pump maintenance on their own.

For frequent media change, utilisation of a mass flow controller is recommended. Our coriolis mass flow controller measures the current flow rate, compares it to the setpoint and then sends a corrected output signal to the pump. With this control loop setup, accuracy and precision is ensured independent from the liquid type.

Are the dosing pumps that Knauer offers compatible with biological fluids?

For biocompatible dosing, we offer metal-free pumps of our FPLC systems with flow rates of up to 2.4 l/h. For higher flow rates, our preparative pumps with titanium pump heads can be used. They cover flow rates of up to 48 l/h at operating pressures of up to 400 bar.

Which features of the Knauer dosing pumps ensure accuracy?

After assembly, the pump is calibrated to ensure accurate fluid delivery. The calibration data is stored on the pump head’s RFID chip. When changing the pump head to address another dosing task, for example to realise a higher flow rate, the calibration data is transferred to the BlueShadow dosing pump in order to ensure optimal accuracy for the individual pump head.

What software comes with the Knauer dosing pumps? What does this allow your customers to do?

All dosing pumps can be operated standalone with the touchscreen or display and buttons. Mass flow controllers are shipped with a dedicated control software. For more complex setups with switching valves and detectors, we offer the touch-based software MobileControl, which allows intuitive control with a tablet pc.

How does Knauer react to customer feedback? Can you give some examples of instances in the past where Knauer has had to adapt to a new application?

Due to the high degree of manufacturing we perform in-house, we can adapt our products to special requirements of our customers. One good example is the request for a pump to deliver sulfur trioxide at a very narrow temperature range for synthesis of methanesulfonic acid.

The researchers from the company Grillo had already received a few rejections when they turned to KNAUER. We adapted the materials to the application and were able to provide a heating solution to maintain the desired process temperature. You can read the whole story here.

What is the future of dosing pumps for the industry and for Knauer?

For industry as well as for KNAUER, the ongoing digitalization is a major topic. I believe that in future, intelligent features such as predictive maintenance and integration into process control systems for smart factories will become a major aspect of maintaining competitiveness. Figuratively speaking, a smart dosing pump should be able to order spare parts and call a technician before its performance decreases.

Where can readers find more information?

On our website, we have a section dedicated to dosing pumps. There, all key requirements of a dosing solution are explained and possible solutions from our product portfolio are suggested.

.jpg)

We also offer a product selection guide for dosing pumps, which contains technical information on our pumps and suggested accessories.

About Dr. Florian Glauche

Florian studied Biotechnology at the Technical University in Berlin and continued his PhD at the chair of Bioprocess Engineering. He then joined KNAUER in 2018 as product manager for dosing pumps.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.