Image Credit: Anna-Lena Lundqvist/Chalmers University of Technology

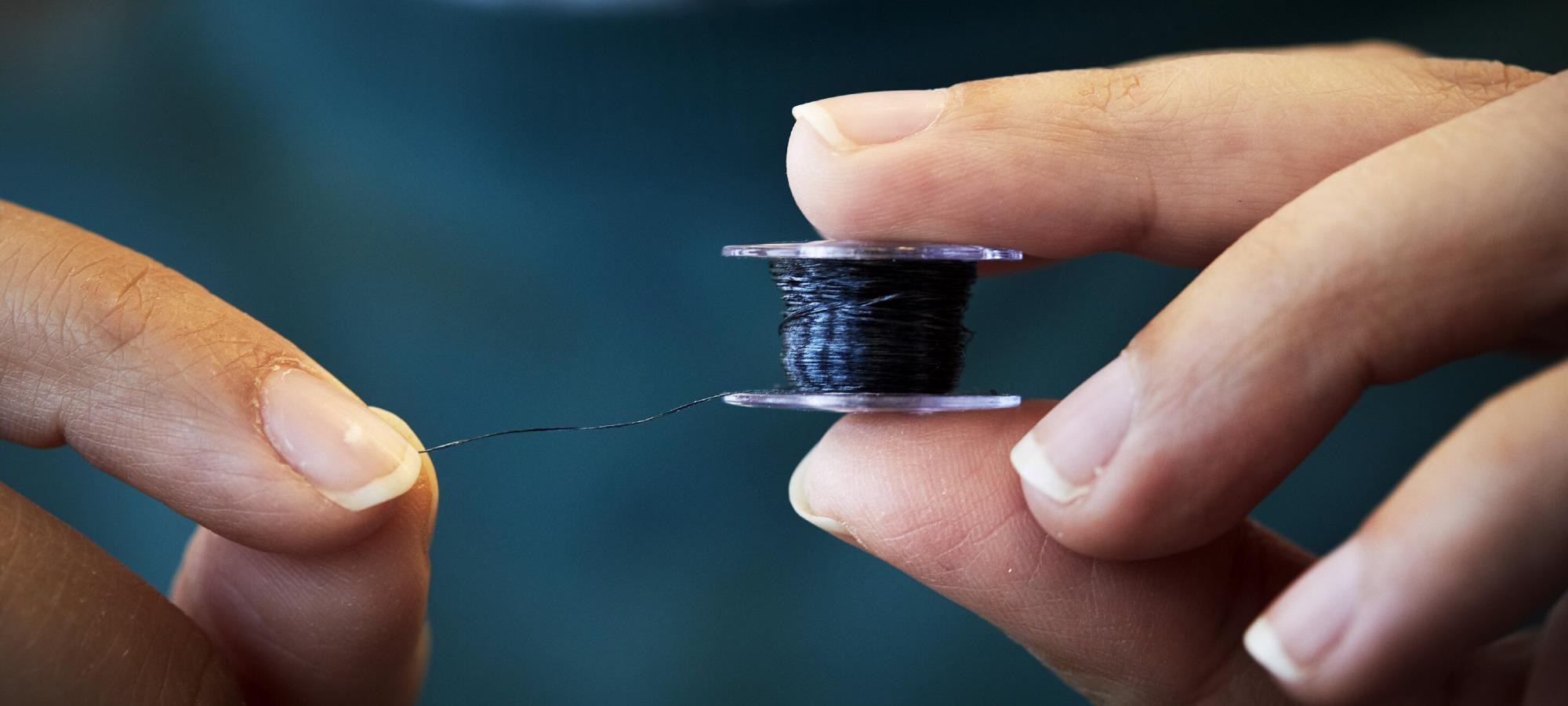

A new wood-based thread that conducts electricity could offer a multitude of practical and attractive possibilities for electronic textiles. The cellulose thread – a green electronic textile or e-textile – could be incorporated into the clothes we wear for energy harvesting and sensing, among many other functionalities.

Function versus Waste

Electronic textiles could revolutionize many fields but may be of particular value to the healthcare industry. Such fabrics could be incorporated into wearables that can monitor, regulate and measure different health metrics. Ideally, the fibers need to be fabricated from renewable materials to ensure they are sustainable, and to avoid depleting valuable, often toxic, resources.

“Miniature, wearable, electronic gadgets are ever more common in our daily lives,” explains Sozan Darabi, a doctoral student from the Department of Chemistry and Chemical Engineering at Chalmers University of Technology in Sweden.

However, active packaging, mini displays, and wearable health monitoring devices do not last very long. They also rely on rare and, in some cases, toxic materials such as gallium arsenide, lead, cadmium, and indium.

“They are also leading to a gradual build-up of great mountains of electronic waste,” adds Darabi. “There is a real need for organic, renewable materials for use in electronic textiles.”

Exciting Electronic Thread

Building on previous work on silk, Darabi and colleague Anja Lund have developed an electrically conductive yarn from cellulose - a vital structural element of the primary cell wall of green plants, and therefore abundant in nature. The cellulose fiber is developed by contemporaries at Aalto University in Finland, who established the production process for the thread.

Image Credit: Anna-Lena Lundqvist/Chalmers University of Technology

The Chalmers researchers dyed the thread with an electrically conductive biocompatible polymeric material, an ink based on polyelectrolyte complex poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT: PSS), in a ‘layer-on-layer’ process.

The cellulose thread exhibited a record-high conductivity as a result of the process, which could be improved with the addition of silver nanowires. The thread can be sewn into fabrics using a simple household sewing machine, with the material able to withstand at least five machine washes without losing its conductivity.

The textile is lightweight, flexible, and in many cases, biocompatible, meaning it is particularly attractive for applications where electronics are worn close to or directly on the body.

“This cellulose thread could lead to garments with built-in electronic, smart functions, made from non-toxic, renewable and natural materials,” says Darabi, who is based at Wallenberg Wood Science Center, which focuses on new materials from trees.

When combined with conjugated polymers or carbon nanoparticles, the cellulose textile acts as an active component in supercapacitors, batteries, LEDs, solar cells, strain sensors, electrochemical transistors, and thermoelectric devices.

The researchers demonstrated this electrochemical functionality by incorporating it into an organic electrochemical resistor to fabricate an energy-harvesting thermoelectric textile. The material produced a small amount of electricity – around 0.2 microwatts – when heated on one side, by a person’s body heat, around 37 °C.

Fast Fashion

Historically, clothes were made from natural fibers, but the mid-20th Century saw the introduction of synthetic fibers in the textile and fashion industries. A culture of ‘throwaway’ or ‘fast’ fashion was born, generating huge amounts of waste. However, a greater awareness of this problem means manufacturers are increasingly revisiting natural fibers and textiles.

Electrically conductive cellulose fibers could have a role to play here too, say the researchers. “Cellulose is a fantastic material that can be sustainably extracted and recycled, and we will see it used more and more in the future,” says Christian Müller, professor at the Department of Chemistry and Chemical Engineering at Chalmers University of Technology and research leader for the study.

“And when products are made of uniform material, or as few materials as possible, the recycling process becomes much easier and more effective,” he adds. “This is another perspective from which cellulose thread is very promising for the development of e-textiles.”

Future Work

The Chalmers team is now envisioning how to take their ideas to the next level with the aim of producing electrical energy in the microwatt range. The hope is that this research into green electronics will allow the textile industry to adopt non-toxic, renewable, and biodegradable organic materials as a solution to the problem of conventional electronics depleting rare resources, while also tackling the global build-up of waste – electrical or fashion related.

References and Further Reading

Chalmers University of Technology (2021) Huge potential for electronic textiles made with new cellulose thread, Cision https://news.cision.com/chalmers/r/huge-potential-for-electronic-textiles-made-with-new-cellulose-thread,c3303002. Accessed 25 March 2021.

Darabi, S. et al (2020) Green Conducting Cellulose Yarns for Machine-Sewn Electronic Textiles, ASC Applied Materials & Interfaces https://pubs.acs.org/doi/abs/10.1021/acsami.0c15399. Accessed 25 March 2021.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.