Recently, there has been exponential growth within the CT systems market. Consequently, a large variety of systems have landed on the market, ranging from giant, flagship systems covering an extensive range of applications down to small desktop devices with satisfactory but limited capabilities.

To determine particular solutions in this extremely competitive landscape, manufacturers would adjust the core function of micro-CT systems, specifically non-destructive acquisition of attenuation-based 3D images, with extra and even novel analytical capabilities.

For instance, the capability to conduct X-ray fluorescence during scans, real phase contrast imaging with grating interferometry, acquiring spectral data inside a micro-CT system or capturing X-ray scattering signals.

Moreover, there is an increasing demand to enlarge imaging from 3D to 4D — introducing the dimension of time to experiments — and a number of CT systems now provide specialized 4D imaging tools, cable feedthroughs for flow and signal lines and built-in connections for peripheral equipment.

Despite an ever-growing range of extra capabilities for micro-CT systems, the production of 3D datasets of a sample’s structure or composition remains the main application for micro-CT.

Regardless of whether such datasets are employed for the quantification of material characteristics, for example, porosity, utilized as input for numerical models or are being used to acquire a deeper understanding of a sample's interior, image quality continues to play a central role in acquiring reliable and reproducible results.

Due to the number of instruments available and a committed user community, micro-CT technology has undergone significant development.

Nowadays, tomography devices come equipped with advanced X-ray sources and detectors, and the accompanying software demonstrates improved reconstruction algorithms and excellent post-processing and visualization tools.

This article outlines what new technologies mean for the most current generation of microCT systems, and illustrates how the quest for the best micro-CT system for any application goes further than simply comparing the maximum resolution of all systems in the market against one another.

This is magnified by the fact that the resolution limit of X-ray sources has hit its absolute physical limits. Now, all X-ray source manufacturers provide transmission-type X-ray tubes with resolutions between 0.5 µm and 1 µm, and the practical difference between these values is extremely limited.

Although the importance of getting high – or rather, satisfactory – resolution on images is a valuable quality, other parameters, including image quality and contrast, imaging speed or simply the dynamic ability of a system, are just as or sometimes even more crucial than resolution.

Imaging Speed Increases Throughput and Saves Cost

Of the most important characteristics to consider when looking into micro-CT devices is imaging duration.

Developments in key scanner components, primarily on the detector side but also in computer hardware such as solid-state drives that facilitate rapid data recording, have driven the reduction in acquisition times — from several hours to just a few minutes.

Additionally, the capability to augment the source-detector distance to maximize X-ray flux indicates that the maximum power of the X‑ray source and acquisition modes also need to be brokered when calculating acquisition speed.

The quickest commercial micro-CT systems on the market facilitate superb scan results at medium resolution in under one minute per scan and can achieve temporal resolutions of just a few seconds at their maximum scan speed.

Fast scan speeds offer numerous benefits, but the key influential factor is likely to be increased throughput. This increased throughput offers the capacity to scan several in a relatively short time, thus enhancing a system’s availability to its users.

As micro-CT devices are usually present in larger, multi-user facilities, this stops system access from becoming a serious bottleneck for experiments and research progress. High throughput enables users to process a lot more samples in the same amount of time, ensuring enough data points are generated to come to statistically relevant conclusions.

In situations where several samples need to be scanned to acquire such a statistically relevant sampling, slow scan speeds are not an option. Finally, rapid scanners also preserve a low cost per sample, which is crucially important in an analytical service lab environment.

While imaging speed is a key factor for all previous points, it also means that – when there is more time – this time can be used to obtain more X-ray projection images or increase the exposure time per projection.

This means that faster imaging speeds mean that enhanced image quality can be acquired within the same acquisition duration as with a slower micro-CT system.

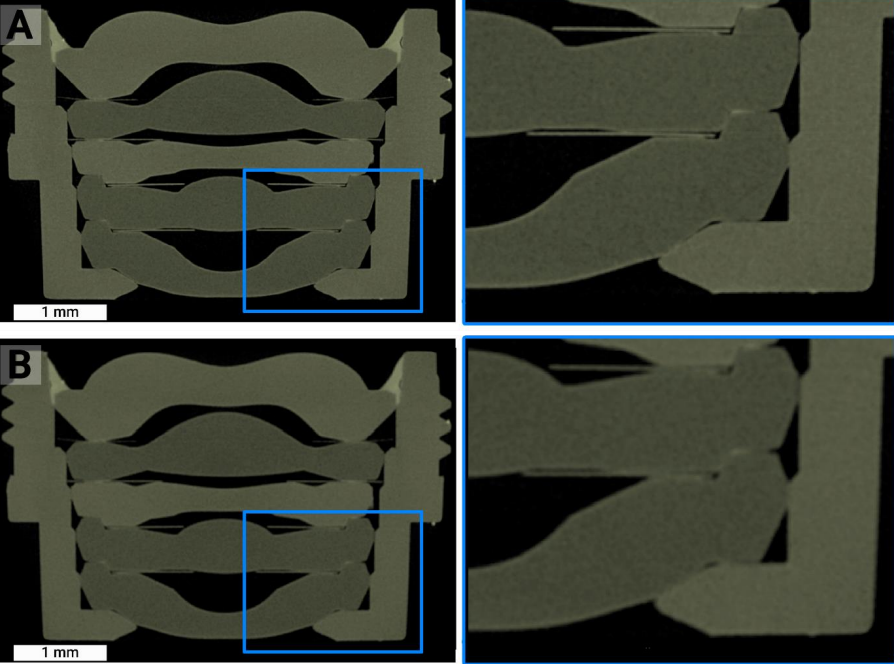

Figure 1. High-quality scans of a phone lens assembly scanned on a TESCAN UniTOM HR system in just 26 (A) or even 7 (B) minutes using 1300 (A) and 1000 (B) projections. Image Credit: TESCAN Group.

Image Quality is the Key to Achieving Actionable Results

The significance of this high image quality cannot be overstated. Overall image quality is quite possibly the most central factor when it comes to obtaining high-quality, reliable, actionable results from micro-CT.

This is of particular importance when numerical results such as porosity values or absolute distances are required. It is critical that signal-to-noise and contrast-to-noise ratios are as high as possible.

A segmentation step is most likely to be the first step in processing and analysis of 3D micro-CT datasets. This image segmentation is typically conducted either automatically or manually, where two or more different materials are differentiated from each other, predicated on their grey value in the images.

As the majority of image analysis routines necessitate at least one segmentation step, and all additional analysis steps and conclusions typically rely on that initial segmentation, it is considered to be the single most crucial step in image analysis.

Therefore, image quality plays a central role in getting excellent results. The better the input, the more dependable image segmentation can be executed by different users or algorithms.

This is highlighted with the rise of advanced machine learning and AI-assisted segmentation methods, all conditional on clean and consistent training data. Much like imaging speed, image quality also has taken advantage of technological progress in electronics.

There has been a decline in the read-out noise from detectors, and more has been learned about implementing and finetuning detectors for computed tomography (which is different than for industrial radiology).

Better acquisition modes, such as smooth acquisition trajectories as opposed to the conventional step and shoot method, increased the signal-to-noise ratio on some micro-CT systems.

As previously mentioned, as the resolution of a micro-CT system is one of the most crucial aspects of the technology, it cannot be ignored. Resolution is a vital component of the image quality of the datasets produced by a system.

There are certainly applications where sub-micron spatial resolution is required to solve any impending challenges. However, users must understand that they can only gain an advantage from that (theoretical) maximum resolution if the features can be resolved and segmented with sufficient confidence to guarantee accurate results.

If there is a reduction of the signal-to-noise ratio at maximum resolution, the compromise in image quality may be too big of a tradeoff.

If maximum resolution is not the most crucial factor – and there are a number of applications where this is the case – it is worth taking into account micro-CT systems that possess a resolution of a few microns rather than sub-micron but excel in other aspects.

These lower-resolution systems can provide greater ease of use, lower maintenance needs and increased flexibility in terms of sample and system geometry.

Versatility Matters: It Might be Needed One Day

While rotation of the sample is enough on its own to obtain a standard micro-CT 3D dataset, such systems, with only one degree of freedom, are difficult to acquire and are only employed in particular cases, like inspection of multiple identical samples in an industrial environment.

The majority of commercial CT systems are flexible enough to move the sample between the X-ray source and the detector (for magnification) and enable sample movement up and down (for scanning of tall samples).

In most other cases, this is complemented by a variable source-detector distance, usually in fixed steps rather than taking steps that are fully adjustable and/or side-by-side movement of the detector for wide-field imaging.

Taking this further, there are devices that offer a positioning stage on top of the rotation stage to fully align the sample above the rotation axis. This X/Y positioning is typically executed by relative positioning, as opposed to using motors with absolute encoders.

Versatility in a micro-CT system means that users not only have the ability to control the aforementioned movements but also to change the horizontal and vertical position of the X-ray source and detector independently, translate the object stage perpendicular to the source-detector axis and generate acquisition trajectories utilizing a combination of all those movements.

Bringing this all together, these micro-CT systems have a total of 10 or more degrees of freedom to facilitate complete flexibility while accommodating extremely complex tomography experiments.

An example of this versatility and excellent use of the available degrees of freedom is the renowned multi-scale approach that is commonly used for micro-CT investigations.

Once a fast overview scan of a large object has been performed, which in micro-CT may be tens of centimeters in height and diameter, a specific area or volume of interest can be determined inside the sample.

At the location of this volume of interest, a longer, new scan is conducted at higher resolution and/or image quality. Accurate communication among visualization, reconstruction and scanner control software applications is required for the translation of the coordinates between the initial overview scan and the ensuing high-quality scan.

Absolute encoders for every motor inside the CT system make sure that every single component of the micro-CT system is guided towards the appropriate location for carrying out the volume of interest scan.

This multi-scale volume of interest workflow can be completed with the application of most micro-CT equipment, but only a supreme connection between software and hardware facilitates an easy, user-friendly experience.

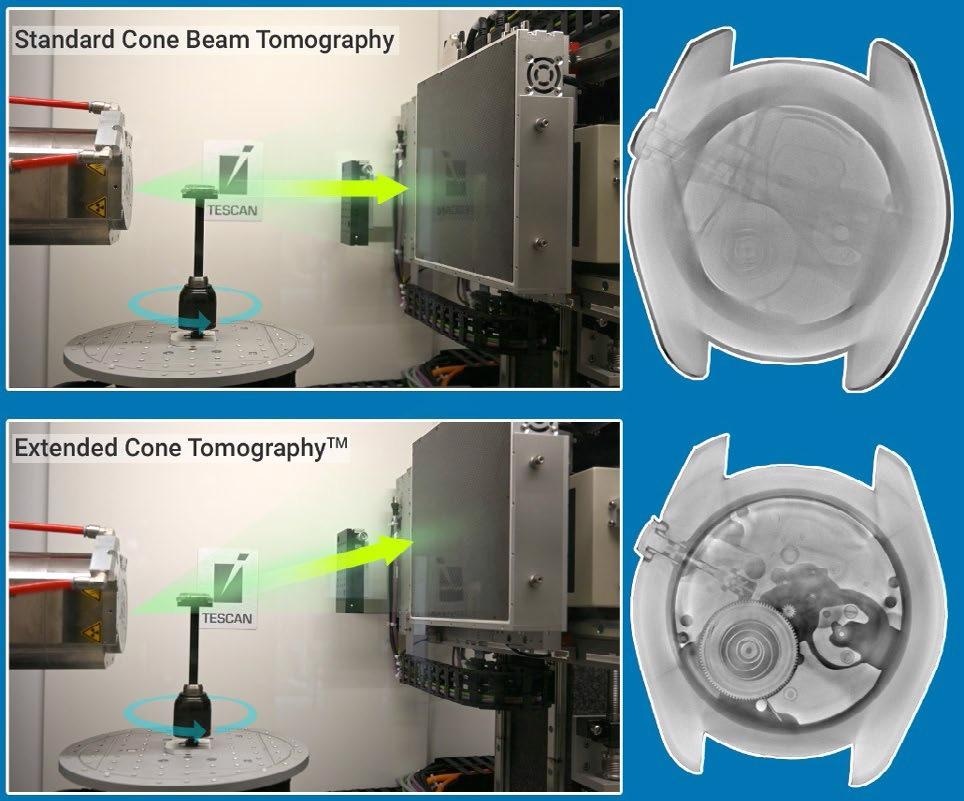

Finally, system versatility also allows non-standard imaging trajectories as well as the conventional circular acquisition scheme.

Helical acquisition is renowned and typically requested, but trajectories could be crucial, such as offset scanning (doubling the field of view for wide samples) or acquisition with a tilted optical axis (where the source and detector are at a different height, to maximize transmission for large, flat samples).

Figure 2. Reconstruction of a stainless steel watch using standard cone beam tomography vs tomography with a tilted optical axis (TESCAN Extended Cone TomographyTM). Image Credit: TESCAN Group.

Modularity – Maximize Your Investment

Micro-CT system versatility can be improved further by adding the option to use several detectors. Each X-ray detector on the market is determined not only by its physical pixel size (pixel pitch), but also by its number of pixels, active area, energy sensitivity and scintillator thickness.

Therefore, varying sample types and sizes, or simply just different research requirements, will benefit from the use of one or the other detector. Encountering the opportunity to readily switch between various X-ray detectors garuntees that the best results can be achieved for an extensive range of samples.

As detector technology develops at an accelerated rate, the highest asset of micro-CT systems - detector modularity - also ensures that novel techniques can be included in your micro-CT system.

It means a system can be improved for multiple fields of application, at present or further down the line, guaranteeing a long and productive service lifetime. This modularity can also upgrade a micro-CT system with various imaging modalities, such as spectral imaging as an add-on over conventional attenuation-based CT imaging.

Dynamic CT – Bringing it all Together

As versatility and modularity facilitate the scanning of an extensive range of samples, it may become necessary to evaluate these samples under varying conditions, such as non-ambient temperature and humidity or mechanical stress.

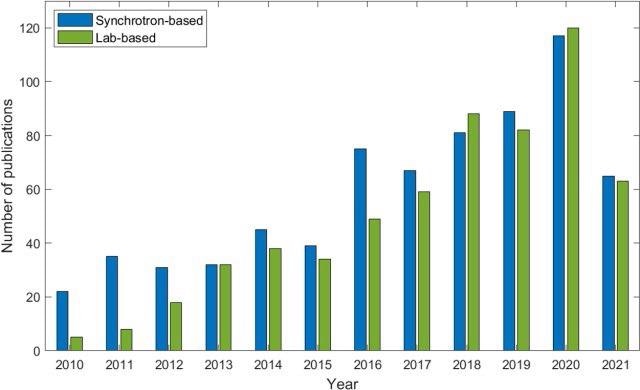

Ever since it was introduced, the non-destructive nature of micro-CT means it has been used for time-resolved studies.

However, recent advances in the aforementioned properties enabled the technology to become available in all labs, not just at large synchrotron facilities, making lab-based time-resolved tomography superior to synchrotron-based experiments in publication numbers.

Looking at the number of publications, applications and possibilities of dynamic micro-CT, the capability to conduct fast 4D experiments on a micro-CT system is something to consider.

To have the ability to conduct rapid dynamic experiments, all components of a micro-CT system must function in perfect harmony to get the job done.

In combination with rapid detectors, a high-power X-ray source is required to maintain short exposure times and scan times that can keep up with the quickest of processes.

Abundant hardware connections for power and signals – ideally through a slip-ring connection facilitating endless rotation of the experiment setup – and additional cable feedthroughs are required to install complex in-situ setups inside the system.

Visualization and reconstruction software must also have the ability to handle data acquired over multiple hundreds of sample (or gantry) rotations.

As no experiment can be predicted perfectly, absolute flexibility in the begin- and end-point of the reconstruction blocks must be in place, not only to capture the precise event of interest but also to limit overhead in time and storage.

Figure 3. The evolution of the number of lab-based and synchrotron-based publications covering fast in-situ micro-CT imaging. Reprinted from Zwanenburg et. al (2021). Image Credit: TESCAN Group.

Conclusions

- TESCAN micro-CT systems deliver superior speed, image quality, versatility,…

- Future-proof solutions

- Complete team of experienced engineers developed in-house. Proven track record, and leaders in the technology (refer to papers of 2003-2005 by Jelle Vlassenbrouck, Denis Van Loo, Bert Maschaele)

DOWNLOAD PAPER NOW

Source: "Resolution, Speed, Image Quality and System Versatility in micro-CT" by Welsey de Boever.

This information has been sourced, reviewed and adapted from materials provided by TESCAN Group.

For more information on this source, please visit TESCAN Group.