The article provides an overview of the TOF technology used in semiconductors and recent studies in this area.

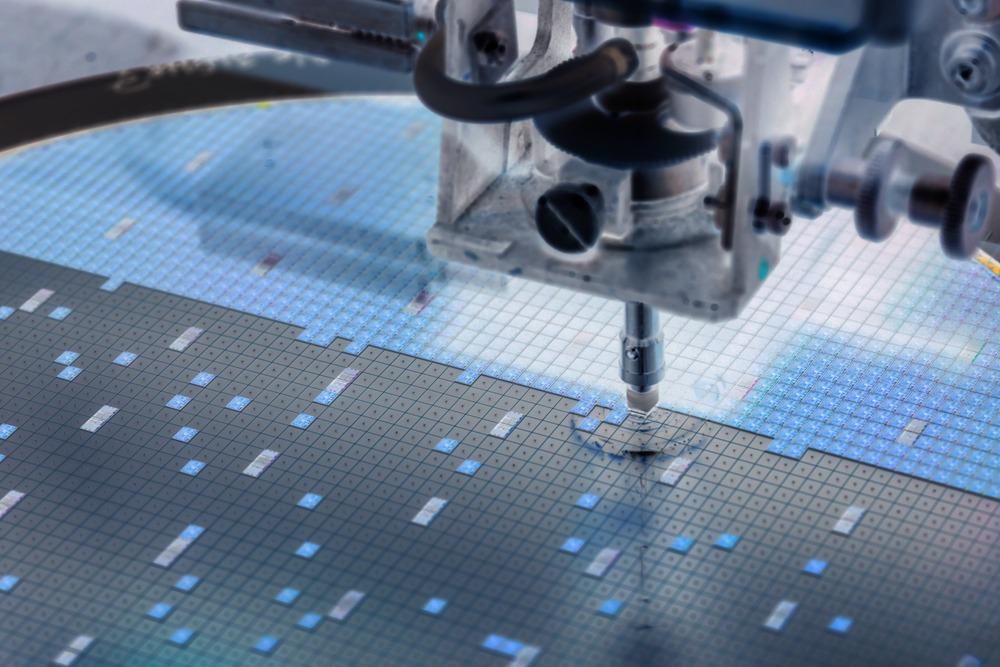

Image Credit: Macro photo/Shutterstock.com

Industries worldwide are developing low-cost and efficient thin oxide film (TOF) semiconductors due to their high performance compared to traditional semiconductors. TOF semiconductors can be used effectively in various applications to improve results. Studies have also demonstrated their application in advanced and futuristic products such as transparent displays, high-temperature devices, and soft materials.

TOF Technology

TOF semiconductors are produced using one or more thin layers of metals in which the thickness ranges from nanometers to micrometers depending on the application. The properties of TOF semiconductors are primarily affected by single or multi-crystalline structures, geometry, microstructure, and production parameters. The application of TOF depends on the semiconductor junction types and performance. They are used to manufacture products such as diodes, transistors, sensors, solar cells, and microprocessors.

TOF devices work by modulating the current flowing through a semiconductor between electrodes. The current modulation is achieved by the capacitive injection of carriers close to the semiconductor interface. The working of TOF semiconductors is also affected by the manufacturing method and the working temperature.

Recent developments in this technology are focused on the dielectric layer of the TOF, which is significant in controlling the processing temperature. The use of appropriate dielectric materials is a critical parameter in the design and manufacturing of TOF. It acts as a channel layer on the TOF, and its properties determine charge accumulation on the semiconductor interface. However, the defects in the dielectric materials such as leakage current, mobility, and photo-stability limit the performance and reliability of TOF.

Notably, the negative bias stress produced in TOF degrades the photo reliability of semiconductors. Additionally, parameters such as reliability, device structure, semiconductor material composition, and passivation also affect the photo reliability. The degradation models such as photogenerated hole carriers and ionized oxygen vacancy models are used to analyze photo reliability in TOF.

Manufacturing TOF Semiconductors

TOF semiconductors are manufactured using transition metals with oxides and electrodes. It must be noted that the use of different types of production processes enables the development of a wide range of properties in TOF semiconductors. The methods also directly affect the structural, physical, and chemical properties of TOF.

The main limitation in traditional TOF manufacturing is the cost and production of the required shape. In contrast, advanced methods used in industry today enable the low-cost production of semiconductor materials with complex structure and geometry.

Aerosol deposition technique (ADT) is a novel method used to manufacture large TOF semiconductors for industrial production. The main advantage of ADT is that homogeneous and continuous TOF production is feasible. The technique can also develop a new-generation ceramic integrated TOF that demonstrates performance improvement and size reduction over the conventional TOF.

Moreover, the TOF devices produced by ADT can be used in micro-mechanical systems, optical devices, and fuel cells. The use of ADT in the manufacturing of TOF semiconductors may also reduce the cost, which is the major challenge faced by the industry.

Recent Research

In a recent study published in the journal Royal Society Publishing, researchers reviewed the use of a nanostructure TOF semiconductor to detect greenhouse gases. They suggested that using TOF semiconductors in greenhouse gas sensors can improve efficiency and effectiveness. Additionally, they also indicated that the development of nanoscale TOF could enhance the performance of a wide range of sensors used to study greenhouse gases.

Conclusion

To summarize, TOF semiconductor-based devices are a rapidly growing field that may replace conventional silicon technology-based products. The main advantage of TOF is that they are non-toxic and demonstrate improved performance. Moreover, studies have shown that TOF semiconductors will develop new fields of research within semiconductors, and they can also be used in concept design products.

The limitation of using TOF devices is cost and difficulty finding rare metals used in certain types of semiconductors. To overcome this limitation, industries have started to use novel materials to substitute rare metals used in TOF, but achieving similar properties is a technical challenge. The other challenge is the requirement to use a complex manufacturing process to produce accurate TOF. Additionally, rapid research development requires increased multidisciplinary partnerships among chemists, physicists, biochemists, and engineers.

Future studies should focus on developing flexible and fully transparent TOF optimized for use at room temperature. The photo-stability of TOF must also be studied in detail to improve performance and stability. Researchers must also focus on developing case studies to use novel TOF in semiconductor devices, which will ensure improvement in their design and manufacturing.

References and Further Reading

Gautam, Y.K., Sharma, K., Tyagi, S., Ambedkar, A.K., Chaudhary, M., and Pal Singh, B., 2021. Nanostructured metal oxide semiconductor-based sensors for greenhouse gas detection: Progress and challenges. Royal Society open science, 8(3), p.201324. https://royalsocietypublishing.org/doi/10.1098/rsos.201324

Fortunato, E., Barquinha, P. and Martins, R., 2012. Oxide semiconductor thin‐film transistors: a review of recent advances. Advanced materials, 24(22), pp.2945-2986. https://onlinelibrary.wiley.com/doi/10.1002/adma.201103228

Sancakoglu, O., 2020. Technological Background and Properties of Thin Film Semiconductors. In 21st Century Surface Science-a Handbook. IntechOpen. https://www.intechopen.com/chapters/71924

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.