Kevlar is a synthetic material created from a chemical known as poly-para-phenylene terephthalamide. Here, we discuss this strong and heat-resistant synthetic fiber Kevlar, its properties, limitations, applications, and recent relevant studies.

Image Credit: Composite_Carbonman/Shutterstock.com

What are Composites?

Composites are heterogeneous materials made of several distinct constituents bonded together, giving rise to better properties. These constituents are generally divided into two main categories: matrix and reinforcements. As the name indicates, reinforcements are the load or impact-bearing components, while the matrix binds them together and provides a cushioning effect in some cases. The properties of a composite may vary from one part to another part of the material, depending upon the material phase, shapes, and alignment of the fibers, and the type of matrix-reinforcement combination used.

There are three main base matrix types: polymer matrix, ceramic matric, and metal matrix, whereas reinforcement can be either particulates or fibers. Different combinations of these produce composites with different unique properties hence infinite applications.

Composite materials with a high strength-to-weight ratio utilized in structural applications are best categorized as high-performance systems and often need regulated production settings for maximum performance. Additionally, a composite can be specially designed to meet the precise mechanical requirements of each particular project, using different matrix-reinforcement combinations or by varying the matrix-reinforcement ratio, resulting in much higher efficiency for end applications.

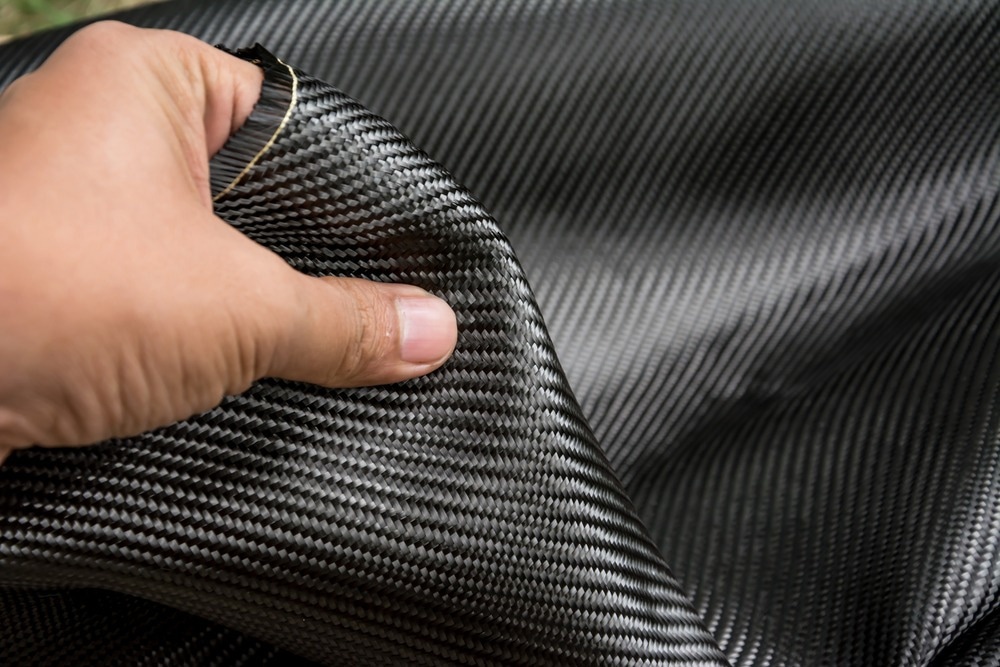

Natural, aramid, carbon, and glass fibers are now the most widely used fibers, followed by polyester and nylon fibers. Short fiber reinforced epoxy resin composites offer useful mechanical qualities. They are used in various industries, including but not limited to friction materials, defense, aerospace, automotive, sporting goods, and chemical engineering.

What is Kevlar?

Kevlar pulp is a kind of short fiber with a high strength-to-weight ratio that is robust and resistant to impact loading. Kevlar is a brand of commercial fibers composed of para-aramids, which are strong, lightweight materials linked to aramids like Technora and Nomex. It is often used in cotton fibers, textiles, and fabrics or as a significant component of composite materials.

Strong and weak electron system linkages in polymer chains' linear and lateral orientations combine to give Kevlar fiber (KF) its yellow hue. In addition, the fibers twist internally if they are bent in a loop. These specific fiber qualities are carried over into the composites. For instance, multilayered Kevlar-epoxy single-direction fibers have lateral weaknesses while being linearly strong.

Limitations of Kevlar

The production of poly-para-phenylene terephthalamide (PPTA) (Kevlar) is costly. Other drawbacks of Kevlar include poor compressive strength, sensitivity to environmental factors compared to other materials, and piercing hurdles (special drill bits are required once it is laminated).

Properties of Kevlar

Kevlar has been shown to be resistant to high temperatures as a fibrous polymer. However, it loses 10%–20% of its stress/tensile resistance at high temperatures, which is further lost after a few hours. For instance, it exhibits a 10% reduction in performance at 160°C over 500 hours of continuous use, and 50% of its resistance is lost in 70 hours at 260°C.

Image Credit: Tagirro/Shutterstock.com

The spun Kevlar produces fibers with a relative density of 1.44 and a stress/tensile resistance of around 3620 MP. The Kevlar structure comprises relatively hard molecules that are often weaved in the form of flat sheets. Kevlar is available in various shapes that may be used alone or in combination with other fibers like glass and carbon fibers to create a composite, depending upon the application. Kevlar fibers have low weight, great toughness, and outstanding thermal stability.

Carbonyl groups and nitrogen-hydrogen generate intermolecular hydrogen bonding. Through stacking interactions between neighboring aromatics, more resistance is created. Arrangement and orientation of the bonds and chains create specific properties, including excellent wear and friction resistance, very low creep, low thermal shrinkage, flame resistant and self-extinguishing, high chemical resistance, high tear resistance, low electrical conductivity, excellent dimensional stability, high modulus, good toughness, low elongation at rupture, high tensile resistance, and low weight.

Relevant Studies

In a study published in 2018, researchers studied the effects of different matrix combinations on blunt trauma and energy absorbed by Kevlar fiber-reinforced polymer laminates. To test Kevlar fiber reinforced polymer composites against a 9mm bullet, samples of the material were made using epoxy and various percentages of rubber and epoxy.

When compared to pure fabric, Kevlar composites and Kevlar with varying amounts of rubber exhibit distinct ballistic impact behavior and back face signature measurements. The trials' findings indicate that adding rubber to the matrix has good effects on energy absorption, the elimination of the back face signature, and the mechanisms causing damage in ballistic impact events.

Applications and Conclusion

Kevlar is a durable, impact-resistant short fiber with a high strength-to-weight ratio. Para-aramids, which are robust, lightweight materials connected to aramids, are the basis of this commercial fiber. It is frequently used to create cotton fibers, textiles, and fabrics and to make up a sizeable portion of composite materials.

Kevlar fiber reinforced polymer composites have been used for various applications in several industries. For example, they have recently been used primarily in the defense industry to manufacture bullet-proof jackets and helmets. Different weave patterns are produced and stacked together to create an excellent composite structure that can resist bullet penetrations and minimize the impact. In addition, compacted Kevlar fabrics are suitable for building cladding, reinforcement, and fabric roofs since they are sturdy, light, and rigid. Furthermore, kevlar and its composites are expected to play a significant role in space applications in the near future to protect space shuttles and communication satellites against impact from space debris.

More from AZoM: How Can a Graphene Composite Aerogel Make Fabric Flame-Retardant?

References and Further Reading

Al-Furjan, M. S. H., Shan, L., Shen, X., Zarei, M. S., Hajmohammad, M. H., & Kolahchi, R. (2022). A Review on Fabrication Techniques and Tensile Properties of Glass, Carbon, and Kevlar Fiber Reinforced Polymer Composites. Journal of Materials Research and Technology.

Jang, B. Z. (1992). Control of interfacial adhesion in continuous carbon and Kevlar fiber reinforced polymer composites. Composites science and technology, 44(4), 333-349.

Pasha, R. A., Nasir, M. A., Anjum, N. A., & Sardar, H. W. (2018). Effect of Rubber particles on kevlar fiber reinforced polymer composite against high velocity impact. Technical Journal, 23(1).

Kowsari, E., Haddadi-Asl, V., Ajdari, F. B., & Hemmat, J. (2019). Aramid fibers composites to innovative sustainable materials for biomedical applications. In Materials for Biomedical Engineering (pp. 173-204). Elsevier.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.