Argon is part of a group of elemental gases known as noble gases. Each of the gases in this group consists of atoms whose outermost “shell” of electrons is fully occupied (helium, neon, krypton, xenon, radon, and argon gas). The result of this unique electron structure is that all noble gases are remarkably inert and can resist chemical reactions even with incredibly reactive substances.

In addition to being gaseous at room temperature, the high levels of inertness mean that noble gases are extremely useful in electronics. Noble gases such as argon can be used within these applications to provide a protective inert environment for sensitive materials and components. This prevents them from reacting with water vapor, oxygen, and other gases in the air.

Argon gas is by far the most common of the noble gases. It can be readily obtained through the cryogenic distillation of air as it makes up around 0.9% of Earth’s atmosphere. Argon is, therefore, the cheapest noble gas, meaning it is favored for applications in electronics manufacturing wherever nitrogen is not able to provide a sufficiently high level of inertness.

Argon gas, alongside its inertness, is also straightforward to ionize, making it extremely valuable as a primary plasma gas.

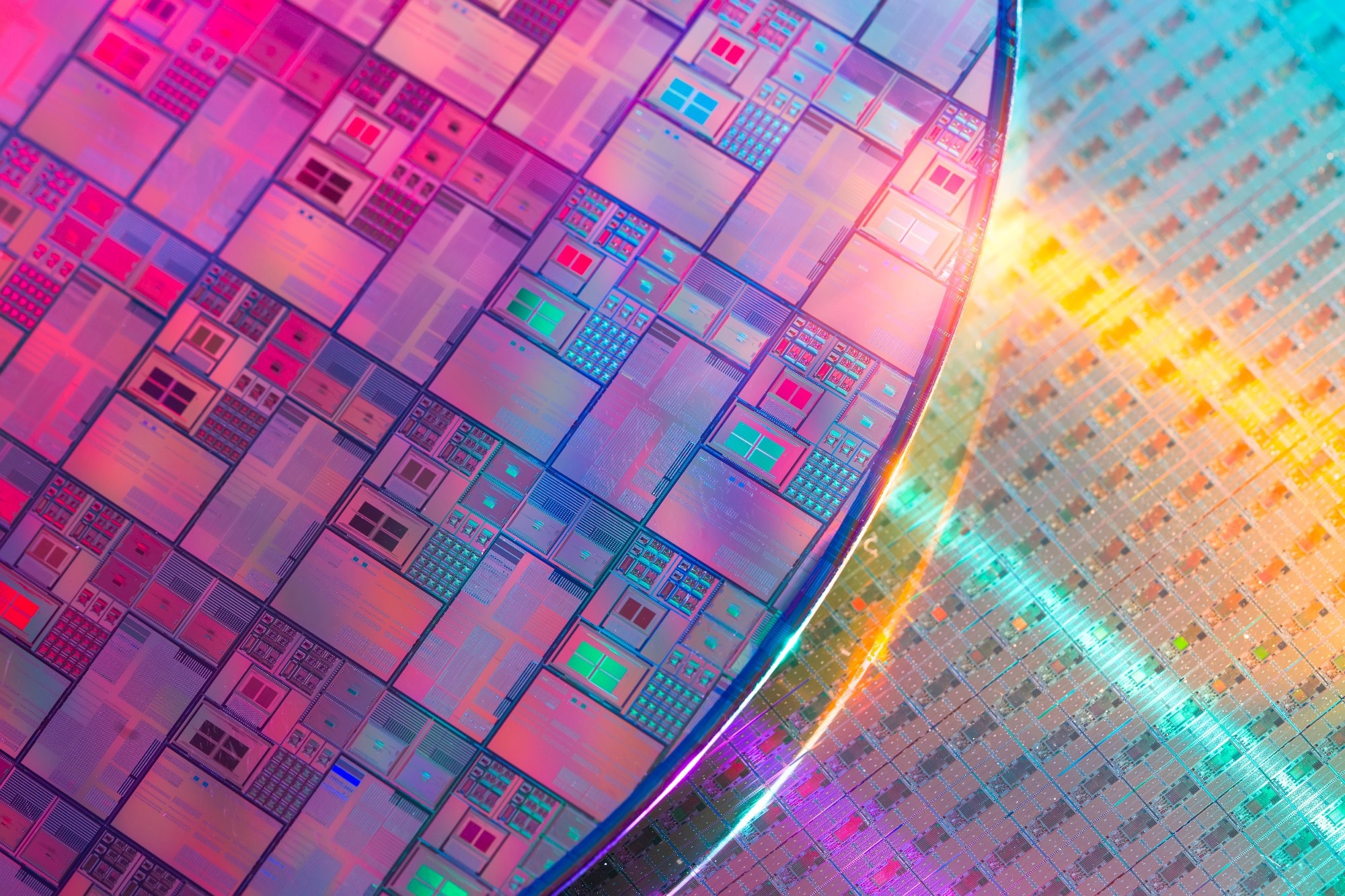

Image Credit: asharkyu/Shutterstock.com

Applications of Argon in Electronics

Throughout many industrial electronics manufacturing processes, argon gas is used to improve efficiency. It provides a dry, inert environment during silicon wafer processing, given that semiconductor devices are incredibly sensitive to oxidation and the effects of water vapor. Argon plasmas are used in deposition and etch reactions, as well as a cryogenic cleaning agent and in deep UV lithography lasers.1

Throughout the electronics sector, argon gas has a range of other applications. Many passive components must be fired during production to bind them to a ceramic board or on-chip components. To prevent unwanted reactions and enable effective bonding to the substrate, argon gas is typically used as a protective inert environment because this is carried out at high temperatures. The production of flat panel displays and photovoltaics modules are examples of other applications of argon gas in electronics, as is the pressurization of LED enclosures to protect the optoelectronic circuitry and increase service life.2

Argon for the Electronics Industry

Argon gas is also provided in various purity grades, mixtures, and supply modes for all electronics, ranging from high-volume applications to specialist high-purity use.

The ultra-pure BIP® Argon from Air Products is unparalleled for instances in which purity is critical. The BIP argon gas offers impurity levels of less than 10 ppb for oxygen, 20 ppb for moisture, and 10 ppb for total hydrocarbons. It was originally developed to eliminate issues associated with impurities in gas chromatography (GC) and inductively coupled plasma spectroscopy (ICP). However with the lowest levels of critical impurities it has also been adopted for specialist electronics manufacturing, such as advanced semiconductor fabrication.

Air Products can provide argon at any required purity level and supply modes. The company can provide the most economical argon gas supply for any application and geographical location, including:

- Argon gas can be provided in compressed canisters, ranging from lightweight portable canisters to 300-bar multicylinder packs for light to moderate use.

- The CryoEase® service from Air Products provides an easy and compact cryogenic supply solution for medium-to-large volume applications.

- For the highest volume Argon user Air Products offers high volume onsite bulk storage tanks, with remote tank monitoring to ensure you never run out.

Air Products offers an argon gas supply mode to suit all electronics applications. Get in touch today with a member of the Air Products team to learn more about how the company can help you achieve your goals.

References and Further Reading

- Tallents, G., Wagenaars, E. & Pert, G. Lithography at EUV wavelengths. Nature Photon, 4, 809–811 (2010).

- OPTO-ELECTRONIC LED MODULES PRESSURISED WITH ARGON GAS. Setga | Outdoor Lighting Manufacturer, https://setga.es/en/opto-electronic-led-modules-pressurised-with-argon-gas/ (2020).

This information has been sourced, reviewed and adapted from materials provided by Air Products PLC.

For more information on this source, please visit Air Products PLC.