This article discusses acrylic acids and acrylates, the processes currently used for their production, the drawbacks of such processes, and the feasibility of the sustainable production of these compounds.

Image Credit: Irina Anosova/Shutterstock.com

What are Acrylic Acid and Acrylates?

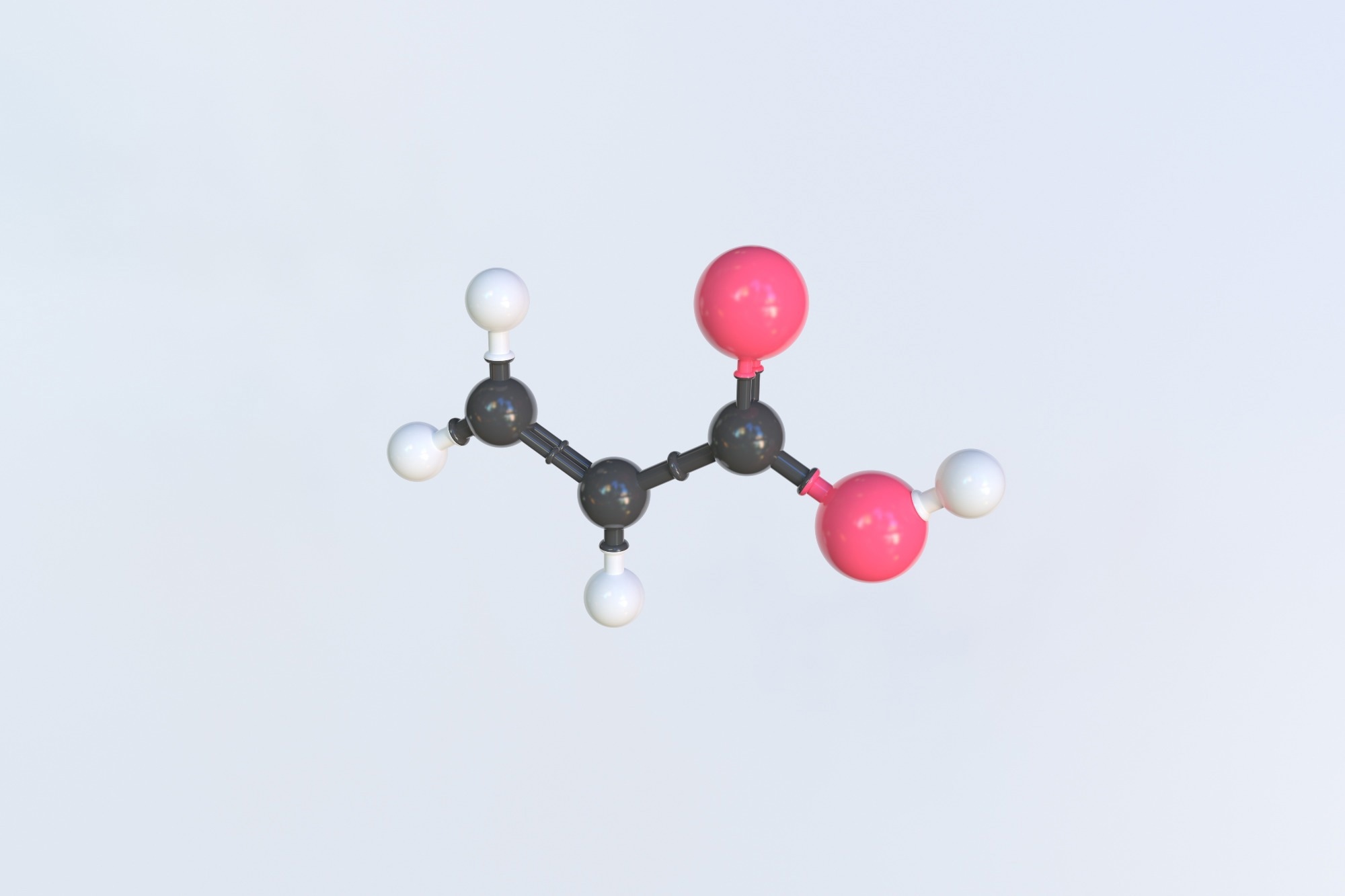

Acrylic acid is an unsaturated carboxylic acid composed of a vinyl group that is directly connected to a carboxylic acid terminus. The organic compound is a colorless liquid with a characteristic tart or acrid odor at room temperature and is miscible with chloroform, ethers, alcohol, and water. The flash, boiling, and freezing points of acrylic acid are 130 oF, 286 oF, and 53 oF, respectively.

Esters, conjugate bases, and salts of acrylic acid are known as acrylates. Materials based on acrylic acid or acrylates possess good transparency, adhesion, stability, and flexibility. Acrylic acid is used extensively in the production of textiles, polishes, paint formulations, elastomers, adhesives, coatings, plastics, wastewater treatment chemicals, and detergents. Acrylates are utilized in cosmetics, diapers, orthopedics, bone cement, and contact lenses.

Currently Used Acrylic Acid and Acrylate Production Processes

Acrylic acid is primarily produced through the vapor phase oxidation of propylene, a gaseous by-product obtained during petroleum refining. The process involves two reactors in series using two catalysts. In this process, the first reactor converts propylene to acrolein while the second reactor converts acrolein to acrylic acid, the final product.

Acrylates are prepared industrially by treating an acrylic acid with the corresponding alcohol using a catalyst. The reaction with lower alcohols such as ethanol and methanol occurs at 100–120 °C using acidic heterogeneous catalysts. In comparison, the reaction with higher alcohols, such as n-butanol, is catalyzed in a homogenous phase using sulfuric acid.

Drawbacks of the Existing Processes

The existing acrylic acid production process leads to a significant amount of atmospheric carbon dioxide emissions and requires the constant availability of fossil raw materials, which necessitates the identification of alternative sustainable and large-scale acrylic acid production processes based on the use of renewable biomass feedstock.

Sustainable Production of Acrylic Acid and Acrylates

In the last few decades, the corn industry has been involved in the sustainable production of several useful chemicals, such as lactic acid. Lactic acid is used as a key ingredient for the production of compostable and renewable plastics. It is manufactured biotechnologically through the fermentation of carbohydrates such as starch and sugar, which minimizes oil consumption and lowers the production cost, representing a feasible eco-friendly alternative feedstock for sustainable acrylic acid production.

Lactic acid can be converted to acrylates and acrylic acid through catalytic dehydration. However, high yields of acrylic acid cannot be realized by the catalysts conventionally used for this reaction, making sustainable acrylic acid production expensive and commercially unviable. Thus, new catalysts must be developed to achieve higher acrylic acid yields through catalytic dehydration of lactic acid.

In a study recently published in the Journal of the American Chemical Society, researchers investigated the dehydration of methyl lactate to methyl acrylate and acrylic acid using a sodium-faujasite (Na-FAU) zeolite catalyst impregnated with multifunctional diamines, including 4,4′-trimethylenedipyridine (44TMDP) and 1,2-bis(4-pyridyl)ethane (12BPE).

These multifunctional amines were incorporated in the zeolite catalyst pores to improve the selectivity of the catalyst to methyl acrylate and acrylic acid. The amines were loaded at nominal loadings of 40, 25, 10, and 5 wt% of the Na-FAU framework for independent trials.

Researchers achieved the highest dehydration selectivity of 96 ± 3% for 2000 min time on stream at 300 °C using Na-FAU impregnated with both 12BPE and 44TMDP. Steady-state dehydration selectivity increased from 85% to 96% corresponding with the increase in the nominal loadings of 12BPE or 44TMDP in the NA-FAU 5% to 40%.

Moreover, researchers achieved a high yield of 92% at 96% dehydration selectivity using 44TMDP-impregnated Na-FAU by tuning the weighted hourly space velocity (WHSV) from 0.9 to 0.2 h−1.

The new catalyst formulation significantly decreased the cost of producing sustainable/renewable acrylates and acrylic acid from corn by reducing waste and improving yield. Thus, the new catalyst can considerably lower the price of sustainable acrylic acid compared to the acrylic acid produced from fossil-derived chemicals, generating new economic opportunities.

For instance, Låkril Technologies, a startup company, has planned to manufacture low-cost renewable acrylates and acrylic acid by licensing this highly efficient catalyst technology. The startup aims to develop this technology for the industrial-scale production of acrylic acid. A low-risk and low-cost acrylate and acrylic acid production can be potentially realized due to the sufficient availability of the zeolite formulation.

To summarize, new catalyst formulations such as 44TMDP-loaded Na-FAU can effectively facilitate the sustainable production of acrylic acid and acrylates in a cost-efficient manner, which is essential to addressing the disadvantages of the existing fossil raw material-based production.

More from AZoM: Catalyzing the Sustainable Production of Acrylic Acid and Acrylate from Corn

References and Further Reading

Dauenhauer, P. J., Nicholas, C. P., Vlaisavljevich, B., Lee, C., Pang, Y. (2023). Multifunctional Amine Modifiers for Selective Dehydration of Methyl Lactate to Acrylates. Journal of the American Chemical Society. https://doi.org/10.1021/jacsau.2c00513

Chemical researchers discover catalyst to make renewable paints, coatings, and diapers [Online] Available at https://www.sciencedaily.com/releases/2023/01/230109112714.htm (Accessed on 15 January 2023)

Acrylic acid [Online] Available at https://pubchem.ncbi.nlm.nih.gov/compound/Acrylic-acid (Accessed on 15 January 2023)

Brown, D. (2014). Acrylic Acid. Encyclopedia of Toxicology (Third Edition), 74-75. https://doi.org/10.1016/B978-0-12-386454-3.00220-7

Ajekwene, K. K. (2020). Properties and Applications of Acrylates. Acrylate Polymers for Advanced Applications. IntechOpen. https://doi.org/10.5772/intechopen.89867

Sustainable production of acrylic acid [Online] Available at https://www.crt.tf.fau.eu/forschung/arbeitsgruppen/komplexe-katalysatorsysteme-und-kontinuierliche-verfahren/biomasse-und-nachhaltige-erzeugung-von-plattformchemikalien/nachhaltige-erzeugung-von-acrylsaure/#:~:text=Lactic%20acid%20produced%20by%20fermentation,production%20of%20bio%20acrylic%20acid. (Accessed on 15 January 2023

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.