The term ultrapure water (UPW) is widely used across many industries—but the definition isn’t universal. While each industry uses what it calls ultrapure water, the quality requirements can vary significantly. For example, the UPW used in a power plant differs from that required in semiconductor fabrication or pharmaceutical manufacturing.

To address these differences, various organizations have developed specific standards for UPW production. These include ASTM D5127 for the electronics and semiconductor industries, EPRI for power generation, and USP, EP, and JP for pharmaceutical applications.

Despite the differing standards, some UPW applications overlap. Both semiconductor fabs and pharmaceutical companies, for instance, use UPW as a rinsing or cleaning agent. However, in pharma, UPW often plays a more critical role—as an ingredient in final products or in steam generation for sterilization. That’s why pharmaceutical-grade UPW must meet stricter criteria, not only being extremely low in particles, silica, and non-volatile residue, but also completely free of microbes, viruses, and endotoxins.

To reach these levels of purity, water is treated in multiple stages:

- A pretreatment stage to generate purified water

- A primary purification stage for further refinement

- And a polishing stage—a continuous recirculation and distribution process that maintains water purity

The polishing stage consists of several treatment steps and typically involves a recirculation and distribution loop. This system continuously treats and recirculates purified water to maintain consistently high purity levels in the supply.

Conductivity measurement is a common indicator of ionic contamination, typically caused by breakthrough from a depleted ion exchanger. UPW is also easily contaminated by traces of carbon dioxide from the atmosphere entering through tiny leaks.

Carbon dioxide forms conductive carbonate or hydrogen carbonate ions, as well as hydrogen ions in the water. For these reasons, real-time monitoring of contamination using conductivity sensors installed in the main ultrapure water system is essential.

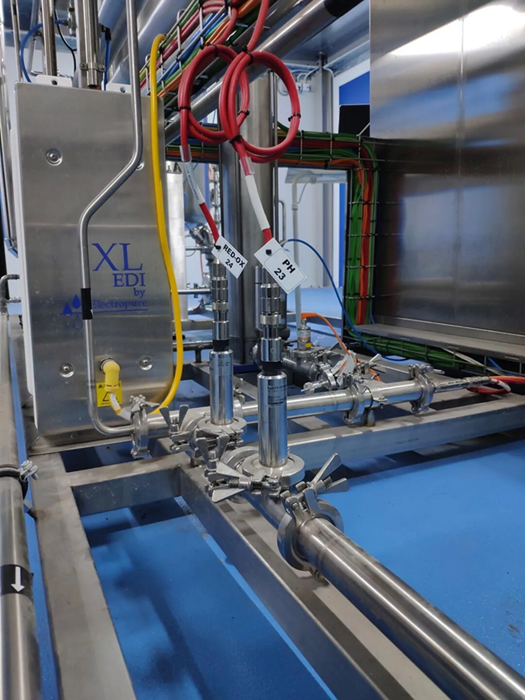

Figure 1. pH and ORP measurement in pretreatment water. Image Credit: Hamilton Bonaduz AG

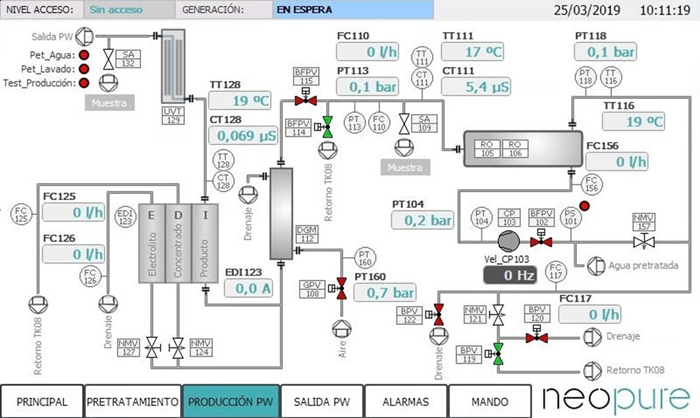

Figure 2. Process Control System of Pure Water Production. Image Credit: Hamilton Bonaduz AG

CCIFA Group is widely recognized for its expertise in engineering, designing, installing, and maintaining purified water systems and Water for Injection (WFI) loops. Its skids are used extensively across the pharmaceutical, biotechnology, and food industries.

In addition to building these systems, CIFA also handles the complete automation of all components using Profinet. To ensure seamless integration, the company needed sensors that could provide a robust digital signal directly to the process control system.

Hamilton’s Arc sensors met these requirements. They are configured via an RS-485 interface, which assigns a unique address to each sensor and allows the download of individual configuration files. This makes it easy to replicate settings across devices and store sensor-specific data efficiently.

One of the key advantages of Arc technology is the elimination of bulky external transmitters. This not only reduces the size of electrical cabinets but also improves space utilization. Arc sensors can also be upgraded with wireless adapters, enabling Bluetooth connectivity with smartphones and tablets through the ArcAir app.

Thanks to their high measurement reliability and comprehensive certification documentation, Hamilton’s pH, ORP, and conductivity sensors have become CIFA’s preferred choice for their ultrapure water and WFI systems.

Figure 3. UPW conductivity measurement at the tank outlet after reverse osmosis. Image Credit: Hamilton Bonaduz AG

This information has been sourced, reviewed and adapted from materials provided by Hamilton Bonaduz AG.

For more information on this source, please visit Hamilton Bonaduz AG.