This article is based on a poster originally authored by Ellen Williams, Peyton Willis, Andrew Laroche, and Calvin M. Stewart.

There is an increasing demand for novel materials and parts able to deliver high performance under extreme conditions. This demand exists throughout various industries, including defense, aerospace, and energy.

Multi-material additive manufacturing (MMAM) has emerged as a potential means of addressing this demand, representing a promising alternative to conventional subtractive manufacturing.

MMAM facilitates the spatial tailoring of materials within a single part, varying a structure’s chemical composition to generate a functionally graded microstructure and other desirable properties.

Spatial materials design strengthens a part against various phenomena while simultaneously reducing weight and cost. This article discusses the characterization of parts enhanced for strength and ductility by transitioning from stainless steel 316L to Inconel® 718.

Understanding microstructure, mechanical properties, and chemistry is required to effectively characterize functionally graded materials and determine an optimal alloy blend. The chemistry of manufactured materials is a primary determinant of their mechanical properties and performance, meaning that determining the spatial distribution of elements within the material is key.

Most high-sensitivity techniques for measuring a material’s chemical composition are limited to bulk analyses, preventing the in-depth visualization of the chemistry of a functionally graded zone.

A novel technique combining Laser Ablation Laser Ionization with Time of Flight Mass Spectrometry (LALI-TOF-MS) delivers detailed spatial characterization via elemental mapping.

This method rapidly provides millimeter-scale elemental maps with resolutions defined by the ablation laser spot size, which is adjustable from 5-150 microns.

The ablation laser enables direct analysis of any solid material that the 83-mm-by-83-mm analysis area can accommodate. Each pixel features a full mass spectrum of data, facilitating the in-depth visualization of the spatial distribution of any element.

In the examples presented here, elemental maps acquired via LALI-TOF-MS identified the transition zone of a functionally graded material before revealing a distinct zone of mixed chemistry at the interface between two different metal alloys.

It was noted that the width of this interface matched the diameter of the laser used to print the specimen. It is important to accurately characterize the meltpool and alloy’s chemistry in order to develop MMAM parts able to accommodate specific industry performance requirements.

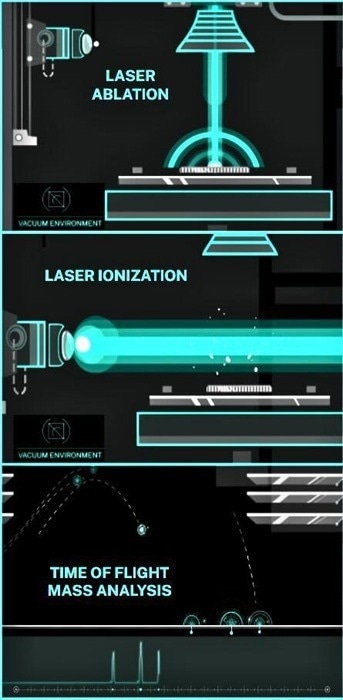

Laser ablation laser ionization time of flight mass spectrometry (LALI-TOF-MS)

Figure 1. Diagram of LALI-TOF-MS. Image Credit: Exum Instruments

Laser ablation (LA)

The first laser is oriented perpendicular to the solid sample's surface, allowing it to ablate or release material. Directly analyzing solid material in this way requires less sample preparation than other analytical techniques.

Laser ionization (LI)

The second laser ionizes neutral particles generated by the ablation process. Compared to conventional plasma-ionizing techniques, targeting neutral particles greatly reduces matrix effects and elemental fractionation.

Time of flight (TOF) mass analysis

Following ionization, particles move through the optics system to the TOF mass analyzer, enabling measurement of the difference in time needed for ions of varying masses to impact a detector.

This step offers a comprehensive mass spectrum, from lithium to uranium, at each laser spot. The complete process is performed under vacuum, significantly enhancing ion transmission efficiency and enabling the analysis of air- and moisture-sensitive materials.

Advantages of LALI-TOF-MS

LALI-TOF-MS provides:

- Trace-level detection from lithium to uranium, with parts-per-million and lower limits

- Elemental mapping on a millimeter scale with micron-level resolution

- Depth profiling with no need for complex sample preparation like cross-sectioning

Image Credit: Exum Instruments

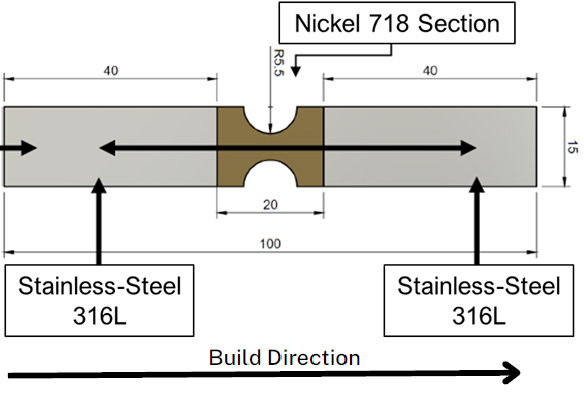

Multi-material additive manufacturing (MMAM) specimen

Figure 2. Diagram of MMAM tensile bar. The tensile bar’s notch was strengthened with Inconel 718 (nickel alloy), which has higher strength than the Stainless-Steel 316L used for the tensile bar’s grips. The arrow indicates the build direction of the additive manufacturing process used to create the tensile bar. Image Credit: Exum Instruments

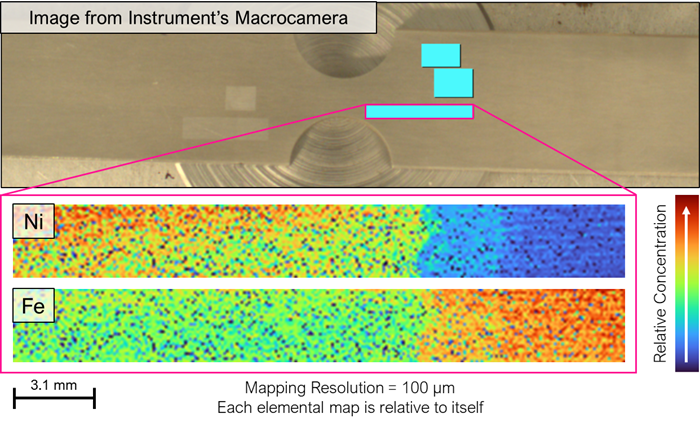

Figure 3. Mapping results acquired by LALI-TOF-MS. The 25-mm-by-3-mm maps have a spatial resolution of 100 microns. The results clearly demonstrate the location of the transition from Nickel (Ni) Alloy with relatively high Ni on the left to Stainless-Steel with relatively high iron (Fe) on the right. Image Credit: Exum Instruments

High-resolution characterization of nickel/steel interface

LALI-TOF-MS generates elemental maps with spatial resolution determined by the ablation laser’s spot size, which is adjustable from 5 to 150 microns. Each laser spot features a full mass spectrum of data, illustrating the distribution of any element of interest.

For example, the relatively large spot size utilized in Figure 3 produces a coarse map, enabling identification of the transition zone between the steel and nickel alloys.

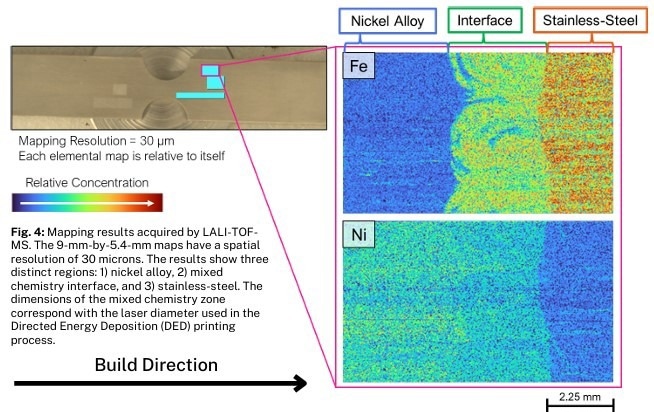

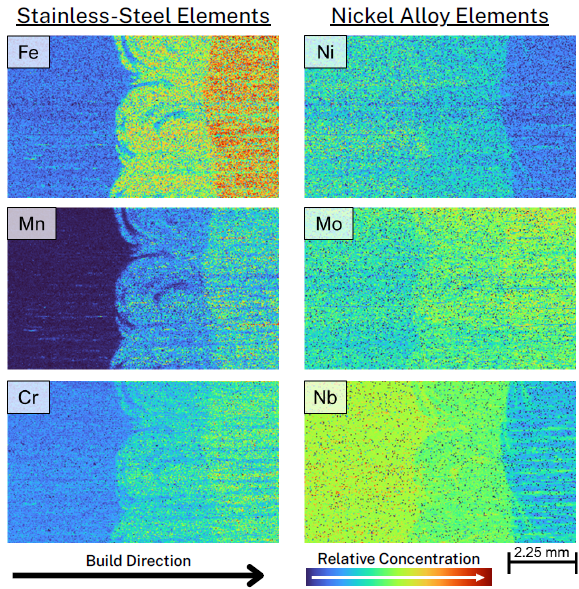

To further characterize the interface, a high-resolution map was performed with a 30-micron laser spot size. The color scale in the image shows the elements’ relative concentrations, with warm colors (such as red) indicating higher concentrations.

The presented maps indicate three distinct regions:

- Left: Nickel alloy (Inconel 718)

- Right: Stainless steel (316L)

- Middle: Interface’s region of mixed chemistry

Figure 4. Mapping results acquired by LALI-TOF-MS. The 9-mm-by-5.4-mm maps have a spatial resolution of 30 microns. The results show three distinct regions: 1) nickel alloy, 2) mixed chemistry interface, and 3) stainless steel. The dimensions of the mixed chemistry zone correspond with the laser diameter used in the Directed Energy Deposition (DED) printing process. Image Credit: Exum Instruments

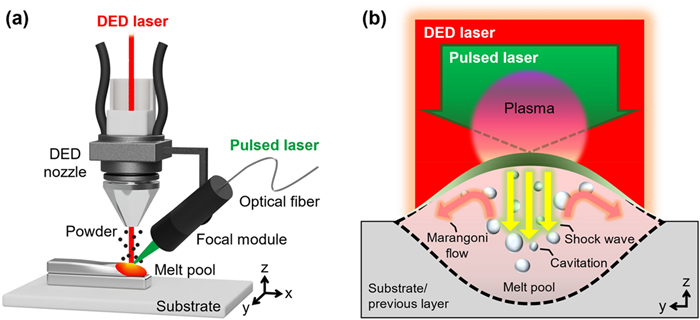

Figure 5. (a) Diagram of the Directed Energy Deposition (DED) process. (b) Diagram of the complex process occurring in the melt pool created by the DED laser. Image Credit: Exum Instruments

Investigating the meltpool mixing and compositional gradient zone

Figure 5 shows how the MMAM specimen was built using blown powder Directed Energy Deposition (DED). This process involved a discrete transition between stainless steel 316L and Inconel 718 in a single-layer pass to create a notch-strengthened tensile bar.

The compositional gradient zone was generated using a combination of Marangoni meltpool mixing and partial remelting of the previous layer as the powder type was switched.

Figure 6 features a series of high-resolution elemental maps generated via LALI-TOF-MS to characterize the compositional gradient zone.

Key findings

The generated maps show meltpool beads with sizes and shapes consistent with DED laser parameters.

Fe, Mn, and Cr maps feature Marangoni flow patterns in the compositional gradient zone, such as swirls of non-uniform chemistry. The zone was also noted to be comprised of intermixed chemistry between the stainless steel and nickel alloys.

The intermixed region included a non-uniform chemical gradient with some alloy elements more diffused than others.

It was determined that inadequate laser DED parameters at the interface were responsible for Marangoni flow defects, but it is possible to heal these defects and further engineer the chemical gradient via heat treatment.

Characterizing the phase formation in the compositional gradient zone allows one to determine the role that different alloying elements play in the MMAM structure. Ascertaining its quality is critical because the interface between different materials is susceptible to defects.

Figure 6. High-resolution elemental maps acquired by LALI-TOF-MS. Elemental maps on the left include major elements in Stainless Steel 316L and those on the right include major elements in Nickel Alloy 718. Results are not limited to the elements shown here. Image Credit: Exum Instruments

Summary

Developments in additive manufacturing technology allow properties to be altered in functionally graded materials in which chemistry is varied layer by layer.

The design of functionally graded materials necessitates a detailed understanding of the interface between material types. This interface is typically the weakest region due to differences in mechanical and thermal properties.

Careful consideration of printing parameters, alloy chemistry, and post-processing treatments is key to preventing failures.

LALI-TOF-MS helps characterize the functionally graded zone and progress MMAM technology by revealing the meltpool mixing and the chemical compositional gradient.

Download Original Poster

Acknowledgments

Produced from materials originally authored by Ellen Williams, Peyton Willis, and Andrew Laroche from Exum Instruments Inc.; and Calvin M. Stewart from The Ohio State University, Department of Aerospace and Mechanical Engineering and Department of Materials Science and Engineering.

About Exum Instruments

Exum Instruments Inc. is an innovator in powerful, accessible, and user-friendly analytical instrumentation, delivering chemistry at the point of need. Our mission is to empower scientists and engineers to accelerate discovery and development across diverse applications by redefining the possibilities of analytical chemistry. Based in Denver, Colorado, we developed Massbox®, the world's first desktop instrument providing Laser Ablation Laser Ionization Time of Flight Mass Spectrometry (LALI-TOF-MS) offering unprecedented ease of use, speed, and analytical capabilities.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.