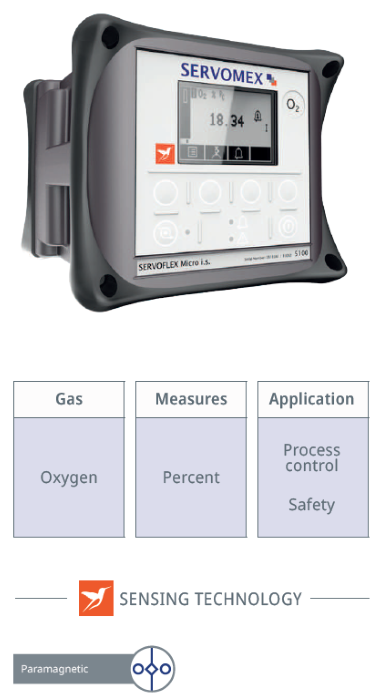

The Micro i.s. 5100 is a unique, intrinsically safe analyzer that measures oxygen percentages in potentially flammable gas samples. It is certified for use in both Zone 0 and Zone 1 hazardous areas.

- High-grade, long-life Li-Ion rechargeable batteries

- Pumped or pressure-driven sample gas options

- Enhanced safety for operation in hazardous environments

- A no-compromise solution

- Designed to work hard

- Portable analyzer for percent levels of O2 (<21 % O2)

- Intrinsically safe – certified to Zone 0 and Zone 1

- Enables analysis of O2 in both flammable and toxic samples

- Ability to store up to 200 measurements

High Performance Portable Oxygen Analysis for Hazard-Rated Locations

The Micro i.s. 5100 is an analyzer designed to meet the demands of the most dangerous environments. It delivers ultra-sensitive oxygen percentage measurements and offers maximum operational flexibility through its durable, life-proof design and feature-rich performance.

The Micro i.s. 5100 is Intrinsically Safe (i.s.) and capable of analyzing flammable and toxic samples. Its intelligent design eliminates the need for a purge before use. The device features an intuitive user interface, can store up to 200 measurements, and offers up to 18 hours of battery runtime.

Enhanced Safety for the Most Dangerous Locations

Environments with potentially explosive atmospheres require robust analytical solutions that enhance safety while providing efficient, engineer-friendly gas measurements. In applications such as catalytic regeneration, decoke cycles, combustion optimization, and hazardous area process monitoring, i.s. certified solutions help reduce costs and improve operational efficiency.

Regardless of the monitoring requirements, an ideal device offers feature-rich performance, low operational costs, long battery runtime, simplified maintenance, and ease of use—without compromise.

A No-Compromise Solution

The Micro i.s. 5100 is a portable gas analyzer designed for hazardous applications, combining an intuitive user interface with an Intrinsically Safe (i.s.) design and ultra-sensitive O2 monitoring.

With flexible options including pumped and non-pumped formats and a range of features to simplify sample testing, the device is designed to perfectly adapt to the job, providing the efficiency and usability users demand.

Works As Hard As The User

The Micro i.s. is a tough, hard-working solution with maximized uptime. It comes as standard with high-grade, long-life Li-Ion rechargeable batteries. The device also includes an integrated digital LCD notepad that can store up to 200 measurements to maximize efficiency.

Unrivalled Performance

- Manufactured by Servomex, with over 70 years of innovation in gas analysis and thousands of units deployed in the field annually.

- Employs industry-leading patented Paramagnetic technology for stable, non-depleting measurements.

Image Credit: Servomex

Low Cost of Ownership

- Utilizes non-depleting sensor technology to minimize ongoing maintenance costs.

- Equipped with advanced Li-Ion rechargeable batteries, providing up to 18 hours of runtime.

Benchmark Compliance

- IECEx/ATEX/UKEX for Zone 0, and FM (USA & Canada) Division 1

Flexible

- IP65 rating

- Intrinsically Safe (i.s.) design allows operation in all hazard-rated locations, including Zone 0/Division 1

- Gas analysis for O2

- Pumped or non-pumped (AFCD pressure-driven) gas sampling

Easy to Use

- Ergonomic design with carry strap

- Intuitive, engineer-friendly interface and icons

- Stores up to 200 measurement points for subsequent review

Key Applications

- Hazardous area combustion optimization

- Process monitoring

- Inerting applications

- Controlled atmosphere monitoring

Specifications

Source: Servomex

| Gas measured |

Oxygen (O2) Industrial

accuracy sensor |

Oxygen (O2) High

accuracy sensor |

| Technology |

Magnetodynamic paramagnetic sensor |

| Performance |

| Measurement range |

0-21 % O2 (0-100 % O2* in safe area locations only) |

| Decimal places displayed |

1 |

2 |

| Linearity error |

±0.1 % O2 |

±0.01 % O2 |

| Repeatability error |

±0.1 % O2 |

±0.05 % O2 |

| Intrinsic error (accuracy) |

±0.1 % O2 |

±0.05 % O2 |

| Response time (T90) |

<15 seconds |

| Zero drift per week |

±0.4 % O2 |

±0.2 % O2 |

| Sample flow variations |

±0.1 % |

Temperature coefÏcient

Zero

Span |

±0.2 O2 per 10 °C (18 °F)

±0.3 O2 per 10 °C (18 °F) |

| Tilt effect |

±0.15 % O2 per 15 º of tilt |

| Pressure effect |

Directly proportional to ambient barometric pressure |

| Power cycle |

±0.4 % O2 maximum |

| Signal outputs |

| Alarms |

Two user-configurable concentration alarms are indicated by an LED, icon display, and audible sounder. Instrument fault alarm indicated by an LED, icon display and audible sounder |

| BATTERY (rechargeable lithium ion) |

Typical running times hours (from fully charged) |

Charge time (from empty) |

| +50 ºC |

+20 ºC |

-5 ºC |

-10 ºC |

| Li-ion (O2) 5110 Pumped |

16.5 |

14.8 |

10.5 |

9.7 |

4 to 6 hours |

| Li-ion (O2) 5111 AFCD |

18.0 |

18.0 |

- |

- |

| Power supply |

The instrument must be charged in a safe area using the 100-240 V charger supplied. The unit is not designed to operate from mains power |

| Note |

The 5100 i.s is suitable for operation in hazardous areas only when powered by the internal battery. The power supply must only be used to charge the internal rechargeable battery when in a safe area.

Lithium-ion batteries have no 'memory effects', so they can be recharged from any charge level, for any duration, and as often as preferred without affecting service life.

To ensure optimum service life of the battery, we recommend:

- recharging the battery after each session of operation

- when not in use, storing (with fully charged battery) in a cool environment and recharging every 2 months

|

| * Sample gases containing levels of oxygen in excess of 21 % must not be measured in a hazardous area, for further information please contact Servomex offÏce |

| Operating environment |

| Temperature |

Operation: -10 °C to +50 °C (+14 °F to +122 °F)

Storage: -20 °C to +60 °C (-4 °F to +140 °F) |

| Relative humidity |

0-95 % RH non-condensing |

| Warm-up time |

Allow 1 hour to meet performance specifications |

| Operating altitude range |

-500 to 2000 meters |

| Ambient pressure |

80 to 110 kPa absolute |

| Sample conditions |

| Sample gas |

Clean, dry at ambient temperature and free from particulates <2 µm (conditioning accessories are available to prepare sample where required) |

| Sample inlet connection |

5 mm OD stub with QuickConnect barb fitting for 5 mm (1/4”) ID tube |

| Sample outlet connection |

5 mm OD stub (sample and bypass) |

| Optional connector |

QuickConnect fitting to a 1/8” NPT threaded fitting |

Maximum inlet

pressure |

5110 pumped (internal sample pump) |

5111 AFCD (with internal automatic flow control device - sample pressure driven) |

| Minimum 80 kPa absolute (11.6 psia) maximum 110 kPa absolute (16.0 psia) typically ±3.4 kPa gauge (±0.5 psig) at 700 ml/min nominal flow |

6.9 kPa gauge (1 psig) 69 kPa gauge (10 psig) |

| Physical |

| Ingress protection |

IP65 |

| Weight |

1.8 kg to 2.3 kg (4.0 lbs to 5.1 lbs) |

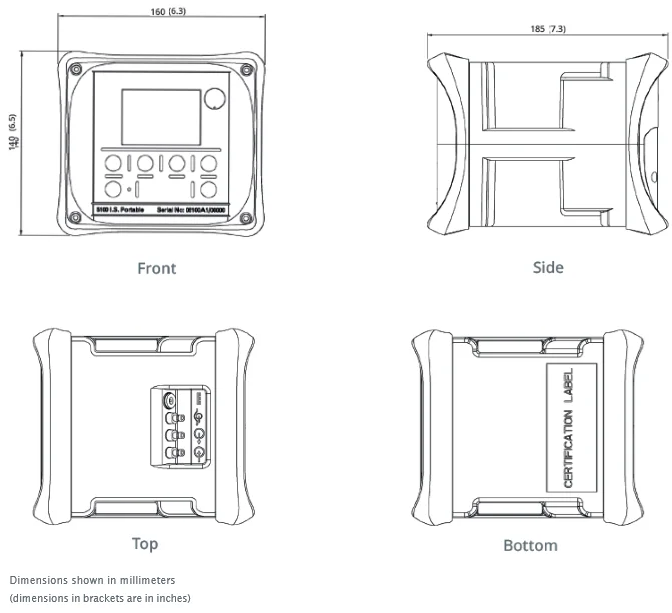

Dimensions,

W x D x H |

160 mm x 140 mm x 185 mm (6.3” x 5.5” x 7.3”) without protective case

175 mm x 160 mm x 195 mm (6.9” x 6.3” x 7.7”) with protective case |

Sample wetted materials. Source: Servomex

| |

Common Gas

Path (inc O2

transducer) |

5110

(Pump option)

adds |

5111

(AFCD option)

adds |

Sample Probe

option adds |

Sample conditioning

panel option

adds |

| 302 stainless steel |

|

|

● |

|

|

| 316 stainless steel |

● |

|

|

|

|

| Borosilicate glass |

● |

|

|

|

|

| Electroless nickel |

● |

|

|

|

|

| Fiber glass |

|

|

|

|

● |

| Fluorocarbon elastomer (FPM) |

● |

|

|

|

|

| Kynar® (PVDF: polyvinylidene disulfide) |

|

● |

|

|

|

| Nickel Plated Brass |

● |

|

|

|

|

| Nitrile |

|

|

|

● |

● |

PPS (polyphenylene sulfide)

with carbon fiber filler |

● |

|

|

|

|

| PPS (polyphenylene sulfide) |

● |

|

|

|

|

| Perspex |

|

|

|

|

● |

| Platinum |

● |

|

|

|

|

| Platinum/iridium alloy |

● |

|

|

|

|

| Polycarbonate |

|

|

|

● |

|

| Polypropylene |

|

|

|

● |

|

| Polysulphone |

● |

|

|

|

|

| Polyurethane |

|

|

|

● |

|

| PTFE |

|

|

|

● |

● |

| PVC (polyvinylchloride) |

|

|

|

|

● |

| Ruby |

|

|

● |

|

|

| Silica Gel |

|

|

|

|

● |

| Silicone |

|

|

|

● |

| Viton® |

● |

|

|

|

|

Compliance. Source: Servomex

| Hazardous area approvals |

| ATEX European |

II 1G, Ex ia IIC T4 Ga (-10 °C < Ta <+50 °C) II 1G, Ex ia IIC T4 Ga (-10 °C < Ta <+50 °C)

(+14 °F < Ta <+122 °F) |

UKEX

Great Britain |

II 1G, Ex ia IIC T4 Ga (-10 °C < Ta <+50 °C) II 1G, Ex ia IIC T4 Ga (-10 °C < Ta <+50 °C)

(+14 °F < Ta <+122 °F) |

IECEx

International |

Ex ia IIC T4 Ga (-10 °C < Ta <+50 °C)

(+14 °F < Ta <+122 °F) |

| FM approved (USA) |

FM: IS/I/1/ABCD/T4; -10 °C ≤ Ta ≤ +50 °C: IP65 (Division 1)

FM: IS/I/0/AEx ia/IIC/T4; -10 °C ≤ Ta ≤ 50 °C: IP65 (Zone 0)

Indoor (IP65) locations |

FM approved

(Canada) |

FM: IS/I/1/ABCD/T4; -10 °C ≤ Ta≤ +50 °C: IP65 (Division 1)

FM: IS/I/0/Ex ia/IIC/T4; -10 °C ≤ Ta ≤ +50 °C: IP65 (Zone 0)

Indoor (IP65) locations |

| EC directive |

This product is in compliance with the EMC Directive, the RoHS Directive, and all other applicable directives. |

| Electrical safety |

Electrical safety to IEC 61010-1 |

Permitted oxygen measurement and sample pressure ranges for hazardous area location use. Source: Servomex

Outside atmosphere

(external environment) |

Portable

type |

Maximum permitted

Oxygen level |

Sample gas

flammability |

Sample pressure |

Permitted |

Zone 1 or Zone 0 Certified Location ≤ 21 % oxygen

11.6 - 16.0 psia (80 - 110 kPa abs) |

5110 pumped |

≤ 21 % oxygen |

Non-flammable

or Flammable |

≤ 16 psia

(≤ 110 kPa abs) |

Yes |

>16 psia

(>110 kPa abs) |

No |

| 5111 AFCD |

≤ 21 % oxygen |

Non-flammable

or Flammable |

≤ 26 psia

(≤ 180 kPa abs) |

Yes |

>26 psia

(>180 kPa abs) |

No |

Options - 5110 (internal pump). Source: Servomex

| Configuration |

|

| 5110 Micro i.s Variants |

We have two pre-configured 5110 (internal pump) builds that cover the most common chosen option configurations to enable a quick turnaround from specification to delivery. |

| Standard Variant 01 (SV01) |

The pre-configured standard variant 1 base level configuration, including the Industrial Accuracy oxygen measurement, for general oxygen measurement requirements. |

| Standard Variant 02 (SV02) |

The pre-configured standard variant 2 base level configuration, including the High Accuracy oxygen measurement, for general oxygen measurement requirements. |

| User Configured (UC) |

Other analyzer configurations not covered by the two above standard variant configurations. |

| Micro i.s. 5110 (Pumped) Portable Analyzer |

|

SV01 |

SV02 |

UC |

| Product Certification |

ATEX Cat1(Zone0)/IECEx/cus |

☑ |

☑ |

☑ |

| Supply power Lithium ion batteries providing 8-36 hours use, depending on sensor selections |

Rechargeable battery UK |

☐ |

☐ |

☐ |

| Rechargeable battery US |

☐ |

☐ |

☐ |

| Rechargeable battery European |

☐ |

☐ |

☐ |

| Measurement |

Oxygen, Industrial Accuracy |

☑ |

◼ |

☐ |

| Oxygen, High Accuracy |

◼ |

☑ |

☐ |

| Sampling system |

Internal pump with user configurable timer |

☑ |

☑ |

☑ |

| Inlet coupler |

1/4” Barb (standard) |

☐ |

☐ |

☐ |

| 1/8” NPT thread |

☐ |

☐ |

☐ |

| |

English |

☑ |

☑ |

☑ |

| Sample accessories |

Not supplied |

☐ |

☐ |

☐ |

| Sample Conditioning Kit Supplied |

☐ |

☐ |

☐ |

| Protective Black Bag |

Not supplied |

☐ |

☐ |

☐ |

| Supplied* |

☐ |

☐ |

☐ |

| Probe holder |

Not supplied |

☐ |

☐ |

☐ |

Supplied: Includes in-line filter if sample

conditioning kit is not selected |

☐ |

☐ |

☐ |

| Sample probe++ |

Not supplied |

☐ |

☐ |

☐ |

| 25 cm, 316 stainless steel, with protective silicone tip (remove protective silicone tip for process temperatures >180 ºC) |

☐ |

☐ |

☐ |

| 1 m 316 stainless steel without protective silicone tip |

☐ |

☐ |

☐ |

Transport/storage case

(safe area only) |

Not supplied |

☐ |

☐ |

☐ |

| Supplied |

☐ |

☐ |

☐ |

| Tick a single box for each selectable option |

| ☐ |

Option selectable |

| ◼ |

Option not available in that variant |

| ☑ |

Pre-selected option |

* Supplied by default if sample conditioning kit selected

++ Option applicable if Probe holder option is selected

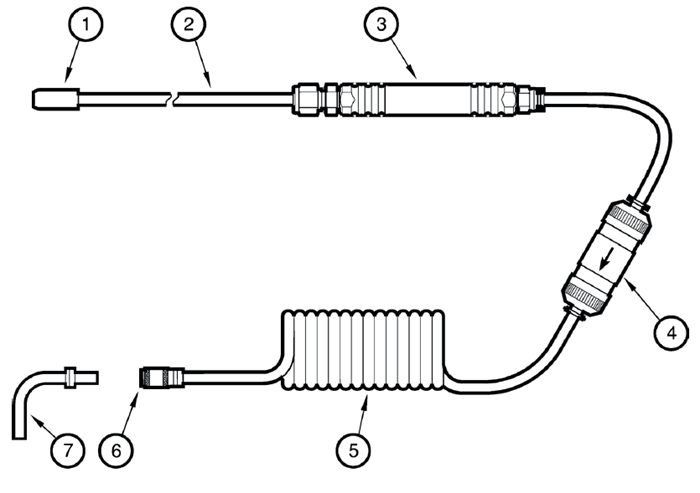

Optional sample gas probe assembly. Image Credit: Servomex

1. Protective tip*

2. Probe (25 cm or 100 cm in length)

3. Handle

4. Filter†

5. Coiled sampled pipe

6. Outlet connector

7. Catchpot inlet adaptor#

* Removable: only supplied fitted to the 25 cm Probe.

† Optional - Filter only fitted if sample conditioning kit is not supplied.

# Only supplied if sample conditioning kit is selected.

Options - 5111 (AFCD pressure driven). Source: Servomex

| Configuration |

|

| 5111 Micro i.s Variants |

We have two pre-configured 5111 (AFCD) builds that cover the most common chosen option configurations to enable a quick turnaround from specification to delivery. |

| Standard Variant 01 (SV01) |

The pre-configured standard variant 1 base level configuration, including the Industrial Accuracy oxygen measurement, for general oxygen measurement requirements. |

| Standard Variant 02 (SV02) |

The pre-configured standard variant 2 base level configuration, including the High Accuracy oxygen measurement, for general oxygen measurement requirements. |

| User Configured (UC) |

Other analyzer configurations not covered by the two above standard variant configurations. |

| Micro i.s. 5111 (AFCD) Portable Analyzer |

|

SV01 |

SV02 |

UC |

| Product Certification |

ATEX Cat1(Zone0)/IECEx/cus |

☑ |

☑ |

☑ |

Supply power Lithium-ion batteries

providing 8-36 hours of use, depending on sensor selections |

Rechargeable battery UK |

☐ |

☐ |

☐ |

| Rechargeable battery US |

☐ |

☐ |

☐ |

| Rechargeable battery European |

☐ |

☐ |

☐ |

| Measurement |

Oxygen, Industrial Accuracy |

☑ |

◼ |

☐ |

| Oxygen, High Accuracy |

◼ |

☑ |

☐ |

| Sampling system |

Pressure-driven AFCD

(Automatic Flow Control Device) |

☑ |

☑ |

☑ |

| Inlet coupler |

1/4” Barb (standard) |

☐ |

☐ |

☐ |

| 1/8” NPT thread |

☐ |

☐ |

☐ |

| User manual |

English |

☑ |

☑ |

☑ |

| Protective Black Bag |

Not supplied |

☐ |

☐ |

☐ |

| Supplied |

☐ |

☐ |

☐ |

| Probe holder |

Not supplied |

☐ |

☐ |

☐ |

Supplied: Includes in-line filter if sample

conditioning kit is not selected |

☐ |

☐ |

☐ |

| Sample probe ++ |

Not supplied |

☐ |

☐ |

☐ |

25 cm, 316 stainless steel, with protective tip

(remove protective tip for process

temperatures >180 ºC) |

☐ |

☐ |

☐ |

| 1 m 316 stainless steel without protective tip |

☐ |

☐ |

☐ |

Transport/storage case

(safe area only) |

Not supplied |

☐ |

☐ |

☐ |

| Supplied |

☐ |

☐ |

☐ |

| Tick a single box for each selectable option |

| ☐ |

Option selectable |

| ◼ |

Option not available in that variant |

| ☑ |

Pre-selected option |

++ Option applicable if Probe holder option is selected

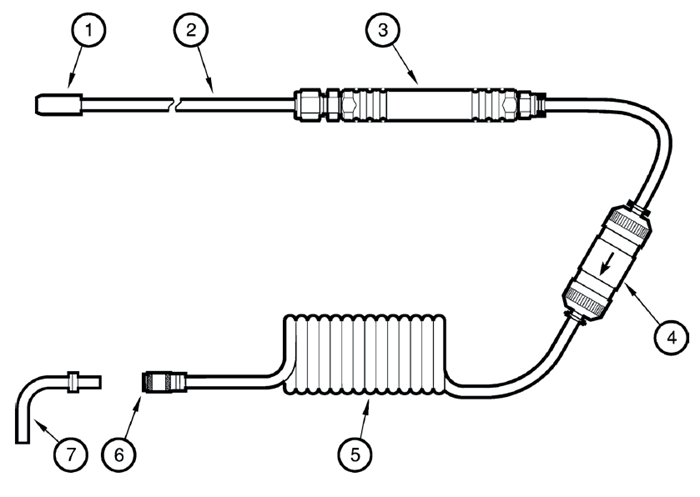

Optional sample gas probe assembly. Image Credit: Servomex

1. Protective tip*

2. Probe (25 cm or 100 cm in length)

3. Handle

4. Filter

5. Coiled sampled pipe

6. Outlet connector

* Removable: only supplied fitted to the 25 cm Probe.

Dimensional Drawings

Image Credit: Servomex