|

Historically, polymer materials were characterized solely by their bulk properties including stiffness, elongation, gas permeability, impact and modulus. Because the bulk polymers were essentially homogeneous, characterization of substructure was not important. Recent advances in polymer science require advanced methods for polymer micro and nano structure characterization.

Polymer Nano-Composite Materials

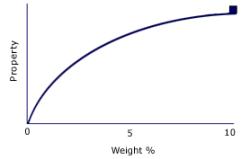

Polymer nano-composite materials are now created having clusters, layers, rods, and networks of nanometer sized materials blended with a bulk polymer. These new materials, such as Nylon-6/clay nano-composites, can have desirable properties such as a high modulus and low gas permeability. Ideally, nano-composite polymer materials show a dramatic increase in a physical property with a small amount of nano-particle additive.

Figure 1. The properties of nano-composite materials can change dramatically with the weight percentage of materials blended or mixed with the bulk polymer.

A unique aspect of the new class of nano-composite polymer materials is the high interfacial volume of the materials, just the opposite of traditional bulk polymers. The chemical and physical properties of the interfaces are what give rise to the unique and often desirable properties of nano-composite polymer materials.

Additionally, polymer materials are being developed for a host of new applications in the high technology and industrial sectors. As an example, low K materials derived from polymers are under development and may replace SiO2 in semiconductor devices.

Polymer coatings are routinely used in packaging applications in the food industry. Such applications require characterization of surface structure and surface properties.

Traditional methods for surface structure characterization are optical and electron microscopes. Besides giving a 2-D projection of the sample topography, the optical microscope can give contrast associated with polarization. However, the optical microscope is limited to resolutions of greater than 0.5 µm . Electron microscopes such as SEM and TEM give high-resolution images but require sample coating to make the polymer electrically conductive. The Atomic Force Microscope is well suited for the characterization of nano-composite polymer materials when compared to traditional microscopes such as the electron and optical microscopes.

Atomic force microscopes give direct 3-D measurements of the surface structure of polymers. Further, using materials sensing modes such as lateral force and phase contrast, it is possible to differentiate the types of materials at a polymer surface.

|