May 12 2001

Image Credit: Maciej Bledowski/Shutterstock.com

This article was updated on 5th Feb 2020 by Clare Kiernan.

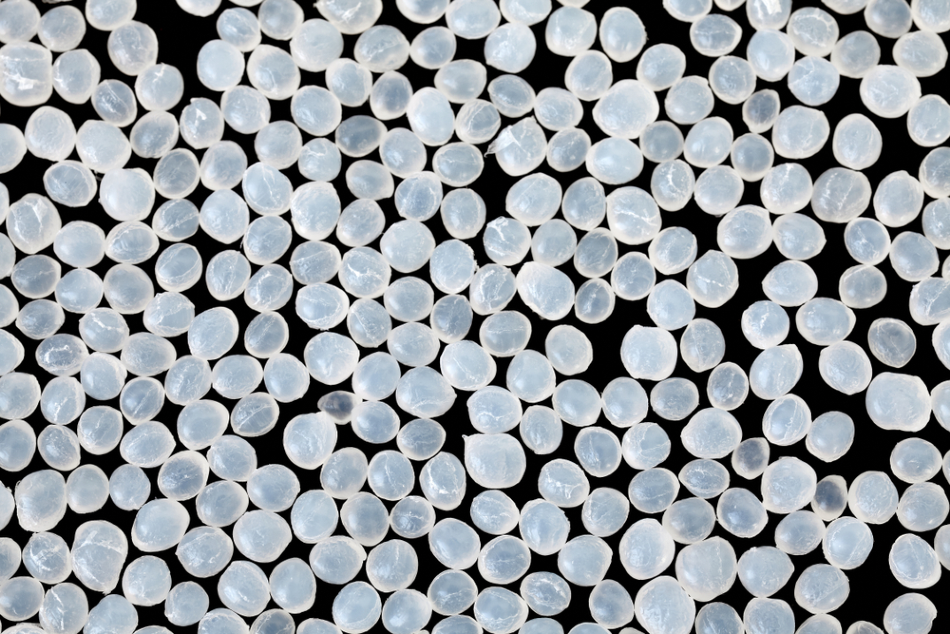

Polyamide 6/12 (PA 6/12) is a thermoplastic with a distinct chemical structure that gives it a low-moisture absorbing property. A large number of carbon atoms separating the amine groups in the polyamide means less moisture is absorbed than other polyamides. This makes PA 6/12 less ductile than PA 6 and PA 6/6 as it does not swell due to moisture absorption. This also causes a reduction in the physical properties of PA 6/12 when compared to PA 6 and PA 6/6.

PA 6/12 can be easily modified to improve its physical properties, and so can be used in several applications that require good physical properties, high heat resistance, chemical and moisture resistance, and good dimensional stability.

Advantages of Polyamide 6/12 Compared to Other Polyamides

- Lower water absorption (4% at saturation) than PA 6 and PA 6/6

- Lower brittle temperature than PA 6 and PA 6/6

- Better heat resistance than PA 6/10

- Lower mold shrinkage than PA 6, PA 6/6 or PA 6/10.

Disadvantages of Polyamide 6/12 Compared to Other Polyamides

- Lower heat distortion temperature than PA 6/6

- More expensive than PA 6 or PA 6/6

Typical Properties

| Property |

Value |

| Density (g/cm3) |

1.06 |

| Surface Hardness |

RR105 |

| Tensile Strength (MPa) |

51 |

| Flexural Modulus (GPa) |

1.4 |

| Notched Izod (kJ/m) |

0.04 |

| Linear Expansion (/°C x 10-5) |

9 |

| Elongation at Break (%) |

300 |

| Strain at Yield (%) |

7 |

| Max. Operating Temp. (°C) |

70 |

| Water Absorption (%) |

0.25 |

| Oxygen Index (%) |

22 |

| Flammability UL94 |

V2 |

| Volume Resistivity (log ohm.cm) |

14 |

| Dielectric Strength (MV/m) |

20 |

| Dissipation Factor 1 kHz |

0.02 |

| Dielectric Constant 1 kHz |

3.6 |

| HDT @ 0.45 MPa (°C) |

160 |

| HDT @ 1.80 MPa (°C) |

80 |

| Material. Drying hrs @ (°C) |

2 @ 90 |

| Melting Temp. Range (°C) |

230 - 280 |

| Mould Shrinkage (%) |

1.1 |

| Mould Temp. Range (°C) |

30 - 60 |

Applications

- Mechanical parts

- Zips

- Filaments

- Coverings and coatings requiring abrasion resistance