Feb 9 2008

The German window system manufacturer aluplast is launching a window system that is highly thermally insulating as well as cost-effective, thanks to a version of Ultradur® High Speed (PBT) which BASF developed especially for this company. This glass fiber-reinforced thermoplastic replaces the steel that is normally used for window frame profiles, thus providing much better heat-insulating features without changing the mechanical properties of the windows. The new profiles do not only save time-consuming and costly work steps for window manufacturers but also weigh 60 percent less than their predecessors containing metal. In early April, aluplast will be introducing this product innovation at the international trade fair “fensterbau/frontale 2008” in Nuremberg, Germany. The new window profiles will already be available on the market by that time. They can be processed on conventional production lines.

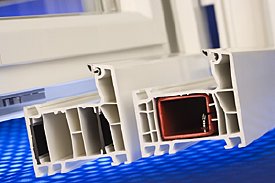

Window frame profiles from aluplast with Ultradur® replacing metal.

Window frame profiles from aluplast with Ultradur® replacing metal.

Thermal insulation improved by 20 percent – thanks to plastic

Two flat strips made of Ultradur are extruded into the new window profile, replacing the metal profile that is usually heavy and difficult to install. “The high thermal conductivity of the metallic reinforcement used so far in the window frames has always resulted in a thermal bridge,” explains Manfred Wüst, head of systems engineering at aluplast. “This is why we joined forces with BASF in the search for a material that would make the window frame as stiff as if it contained metal. At the same time, however, the material was supposed to have better insulating characteristics and contribute to greater energy efficiency in construction.” The U-value (formerly “k-value”: heat transfer coefficient, thus a parameter for thermal-insulation capacity) of the window frame profiles using the flat Ultradur strips is improved by about 20 percent, namely, to 1.1 W/(m² . K), in comparison to the standard versions that contain a steel profile.

PBT instead of metal: light, firm and securely anchored

“Thanks to its extraordinary mechanical features within a wide temperature range, its dimensional stability and its low coefficient of expansion, this plastic is very well-suited for use in window frame profiles,” states Dr. Kay Brockmüller of applications development at BASF Plastics. The Ultradur strips are optimally positioned and permanently anchored in the plastic profiles by means of extrusion. The flat plastic strips also ensure that the window frame profiles are 60 percent lighter in weight, which makes transport and installation easier as well.

In addition – more service for window manufacturers

Window manufacturers can process the new profiles on their current equipment without the need to make additional investments. aluplast extrudes the plastic strips directly into the window frames, thus saving window manufacturers the laborious and expensive steps of steel purchasing, steel logistics and manual steel processing. “The new system is not earmarked as a special niche product; over the long term, we plan to switch over all of our profile systems, thus offering our customers a clear-cut competitive edge. We will start with the market launch of the new product in our large IDEAL 4000® profile line,” explains Manfred J. Seitz, owner of aluplast.

Ultradur® is BASF’s brand name for its partially crystalline, thermoplastic, saturated polyesters on the basis of polybutylene terephthalate (PBT). They are used as materials in the production of high-quality technical parts in many sectors of industry such as automotive construction and electrical engineering. Additional information about Ultradur® can be obtained by writing to the e-mail address [email protected] or by calling phone no. [+49] (0) 621 60 78780. Technical details are also available at www.basf.de/ultradur.

The aluplast group is one of the largest and most innovative international manufacturers of plastic window systems. Today, its brand ranks third in a European brand comparison and seventh worldwide. This year, aluplast is commemorating its 25th anniversary of its founding, having become a global player within a quarter of a century. The aluplast group currently has 22 production sites and sales offices worldwide, with its customers numbering 1600 companies. Using aluplast’s annual production volume of 150,000 metric tons of PVC (for the extrusion of window systems), their customers manufacture 12 million windows per year. Thanks to their strict product policy, their cooperation with partner companies, their flexibility and market-oriented innovations, company owner Manfred J. Seitz and his sons Dirk and Patrick have succeeded in creating one of the most successful companies in the sector within just a few years.

Posted Fenruary 8th, 2008