Jul 2 2010

Siemens Limited China has received an order from Luoyang Longding Alu Co., Ltd., a Chinese company, to supply 26 Siroll ALU TCS process automation systems for its new aluminum rolling mill. The project also includes the first order for new Siroll Heavy Duty Shapemeter flatness measurement systems.

These can measure cold aluminum strip with a thickness of up to 5.5 millimeters. The scope of supply also includes other flatness measurement and zone cooling units. The value of this order lies in the double-digit million US dollar range. The project is scheduled to be completed in September 2011.

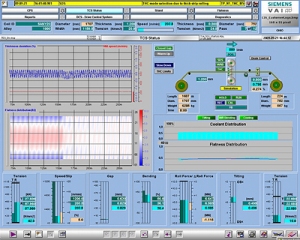

The Siemens Siroll ALU TCS operator control and monitoring interface keeps all the aluminum rolling stand parameters in view all the time.

The Siemens Siroll ALU TCS operator control and monitoring interface keeps all the aluminum rolling stand parameters in view all the time.

The Siemens systems will be installed on cold and foil rolling stands in the new rolling mill. This is the first time that Heavy Duty Shapemeters will be used for the online flatness measurement of cold strip ranging between 0.05 and 5.5 millimeters in thickness. Integrated Automatic Trend Alignment (ATA) guarantees precise positioning of the measuring roller under all operating conditions. Even at slow rolling speeds, the Heavy Duty Shapemeter returns continuous, high-resolution data on the flatness of the strip being measured.

The Siroll ALU TCS process automation system is based on the proven Simatic TDC platform, and will optimize the production flow and improve the quality of the end products. The system contains, for example, components for automatic roll gap control and roll eccentricity compensation to meet these targets. Flatness is measured not only by the Heavy Duty Shapemeters but also by further 22 Siroll Air Bearing Shapemeters, which can measure cold strip ranging in thickness from 0.005 to 4 millimeters. There will soon be over 500 of these flatness measurement systems in use throughout the world. Siemens is also supplying 26 Siroll ISV (Integrated Solenoid Valve) spraying systems for zone cooling and lubricating the rolling stands. Siemens will be responsible for installing and commissioning all the systems, and also undertake the customer training.

The controlling interest in Luoyang Longding Alu is held by the Dingsheng Industry Group, based in Hangzhou, Zhejiang Province. This group of companies currently operates three locations with a total annual production of more than 150,000 tons of rolled aluminum products for use in, for example, the domestic goods, electronics and packaging industries. The new aluminum rolling mill in Luoyang, Henan Province, will increase the annual production capacity to around 300,000 tons.