Polyamide (PA), also known as nylon, is a popular synthetic thermoplastic polymer. Due to its exceptional temperature resistance, automobile manufacturers often utilize it for engine parts, such as air intake manifolds or engine covers.

Image Credit: Sunti Wongyai/Shutterstock.com

It is therefore crucial to maintain the quality of raw materials and processing conditions so that the final material properties of polyamide are suitable for these applications. Polyamide chains degrade when processed at high temperatures and in the presence of a nucleophile such as water.

This results in a decrease in polymer molecular mass and an increase in the number of polymer end groups. This results in a decrease in the viscosity of the polymer melt and the mechanical characteristics of the final product. Adding stabilizers can help to delay the onset of link breakdown.

The Thermo Scientific™ HAAKE™ PolyLab system provides a quick and dependable way for determining the effect of stabilizers on material processing properties.

Test Purpose

To evaluate the efficiency of a stabilizer in polyamide PA6 processing.

Test Equipment

- PolyLab OS Torque Rheometer

- HAAKE™ Rheomix Lab Mixer 600 electrically heated laboratory mixer

- Roller rotors

- HAAKE™ PolySoft™ Software Mixer Software

Test Conditions

- Mixer temperature: 240 °C

- Rotor speed: 60 rpm

- Sample weight: 52 g

Test Material

- Sample 1: PA6 without stabilizer

- Sample 2: PA6 with stabilizer

Test Method

The mixer is heated to the necessary testing temperature, and the drive motor operates at the specified rotor speed. Before the actual measurement, a calibration step is performed to eliminate any potential torque signal generated by the mixer gearbox.

The cold sample material is then swiftly added to the heated, operating mixer, which is closed by the feeding ram. The torque and melt temperature are recorded during the mixing period to determine the sample's melting and processing behavior.

Test Results

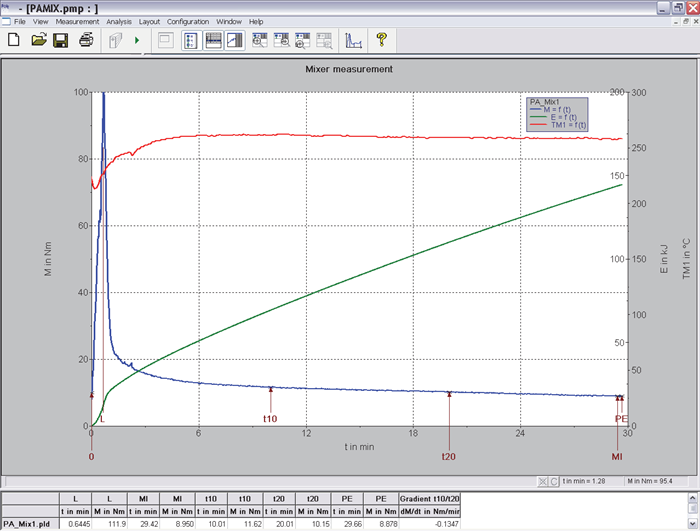

Figure 1 shows the torque-time curve of a polyamide without the addition of a stabilizer. The graph plots torque (M, blue), melt temperature (TM1, red), and energy consumption (E, green) as a function of test time.

Basic Curve Discussion

The first filling of the mixer with the stiff PA sample results in a significant increase in torque, known as the Loading Peak (L). This peak is the commencement time for calculating the substance's various properties.

After the sample material has completely melted, the torque-time curve reveals a consistent reduction in torque. The decrease in torque is produced by a decrease in melt viscosity as the unstabilized sample degrades.

Figure 1. Rheogram of mixer test without stabilizer. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

The characteristic curve points are evaluated using the table below the graph in picture 2. Aside from recording the time, torque, energy, and melt temperature measurements, the gradient between the torque readings after 10 and 20 minutes was determined as a measure of degradation rate.

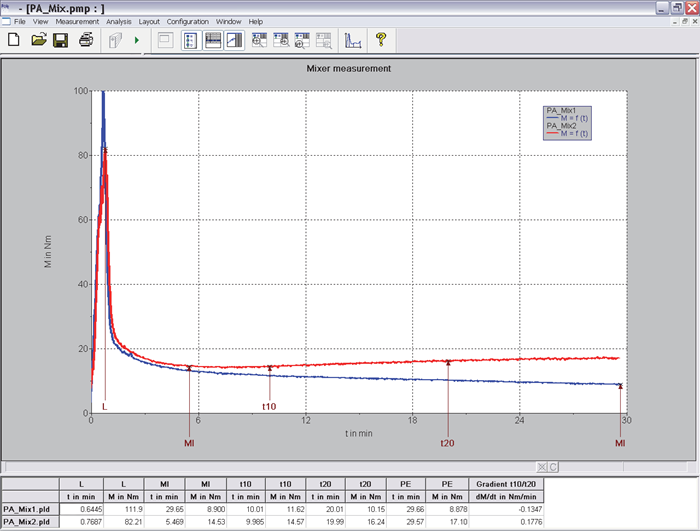

Another mixer test was performed with sample 2, a PA6 polymer compound containing stabilizer. The stabilizer aids in the preservation of polymer end-groups under extreme temperatures, which should result in increased material stability. As a result, the second mixer test should yield a steady torque value.

Comparison of Test Results

Figure 2 shows the torque curves from the mixer tests for the PA with and without the stabilizer in a single graph. The stabilizer's influence is readily obvious. The sample with additional stabilizer (red curve) exhibits a higher torque value in the molten stage.

The torque does not decrease further during the measurement. It can be deduced that the stabilizer prevents polymer chains from breaking and so inhibits polyamide breakdown.

Figure 2. Torque curves of mixer tests for PA with and without stabilizer. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Conclusion

The tests demonstrate that the HAAKE PolyLab Torque Rheometer, equipped with an attached laboratory mixer, is an excellent tool for investigating the flow and processing behavior of polymer compounds. It can aid in the development of a quality control process for PA applications, making it easier, faster, and more reliable to determine final product quality features.

Acknowledgments

This article was produced using materials originally authored by Matthias Jährling from Thermo Fisher Scientific.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Material Characterization.

For more information on this source, please visit Thermo Fisher Scientific – Thermo Fisher Scientific - Material Characterization.