Jul 12 2010

Bytewise Measurement Systems introduced new technology aimed at measuring embossing depth for the decking and siding industries. The system utilizes laser line profile sensors developed by Bytewise for high precision applications.

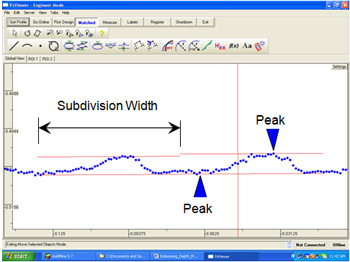

This zoom view shows 0.060 inch wide caliper sub-divisions that calculate the peak-to-peak embossing depth for each sub-division.

This zoom view shows 0.060 inch wide caliper sub-divisions that calculate the peak-to-peak embossing depth for each sub-division.

Embossing quality is a leading aesthetic value that differentiates construction products such as siding, trim boards, and deck boards. Embossing imparts a wood-like characteristic to the appearance of the board surface that buyers find attractive. Many building profiles are manufactured by extrusion processes that apply a weather-resistant capstock over the extruded profile. The profile is then passed through a roll stand that embosses a pattern into the material. Several problems can lead to non-uniform embossing depth.

- Poor roll setup

- Roll wear

- Roll contamination due to transfer of capstock onto the rollers

- Elastic behavior of the compound (die-swell and springback)

Several problems can result:

- Boards with different embossing depths can appear to be different in colour due to differences in shadowing, thus causing customer complaints.

- Excessively deep embossing can weaken the capstock and lead to premature ageing.

Shallow embossing is a serious concern that creates scrap in the production shop, product returns by the distributor, and even returns from the decking contractor. In the worst case, complaints come from home owners who report inconsistent appearance after a deck installation is complete.

There are no industry-wide measurement solutions in use for measuring embossing depth. Some shops make periodic checks off-line using standard lab instruments such as Coordinate Measurement Machines (CMM). Others use hand tools or simple visual checks.

Bytewise has introduced a measurement system for checking embossing depth for use on the shop floor as an off-line QC checking tool. The system can also be mounted on-line to continuously check embossing depth. The system uses a laser line profile sensor manufactured by Bytewise. The system resolution is 0.001mm (0.00004") and measures a 25mm (1") wide section of the profile.

Bytewise Profile Triangulation sensors have been successfully utilized to measure embossing depth in PVC deck and trim boards; WPC deck boards, and vinyl siding. Several advantages have been realized:

- Embossing depth values are automatically measured, calculated, displayed, and recorded.

- Measurements are objective and not operator dependent.

- Complete embossing profiles can be saved for audit.

- On-line measurement can be used to continuously monitor the embossing depth, and alarm the operator when any problem occurs. This can identify problems not possible with periodic off-line checking.

Bytewise are represented in the UK by Nortest.