Tata Steel has started up an advanced facility to develop crash-resistant steels designed to make cars safer and more fuel-efficient. The €2.3 million investment at the company’s IJmuiden site in the Netherlands will increase Tata Steel’s ability to develop next-generation steels which are lighter, stronger and better able to withstand crashes.

Tata Steel crash resist steel car graph

Tata Steel crash resist steel car graph

The R&D investment follows close collaboration between Tata Steel and major European car manufacturers to understand their requirements for future car models. The facility will also enable Tata Steel to support its customers as they integrate the new ultra high strength steels into future vehicles.

The facility is the most technologically advanced in the world, combining the characteristics of commercial industrial lines alongside special research features to control and measure atmosphere, temperature, speed, force, stress and friction. It was upgraded by the two leading equipment suppliers in the field, Schuler and Schwartz, and incorporates a hot press forming line that presses heated steel sheets into vehicle parts1 .

Henrik Adam, Chief Commercial Officer of Tata Steel in Europe, said: “This investment comes out of discussions we have been having with our automotive customers about their visions for the vehicles of the future. This upgraded facility will enable us to work more closely with them, not only to develop the new, advanced steels they increasingly require, but also to help them improve their performance when they process these steels using their own equipment.”

Hot press forming is increasingly being used by automotive manufacturers and their suppliers to manufacture complex body parts2 capable of withstanding impacts. The steels used to make these parts need to be ultra high strength and as light as possible in order to achieve optimum safety and environmental performance.

Such is the growth in their use that hot formed parts make up more than 20%, by weight, of some recently launched car models. The use of steels whose strength has been enhanced through the inclusion of boron is growing particularly rapidly. Tata Steel is developing zinc-coated boron steels, which offer superior corrosion resistance compared to other boron steel grades. In June 2012 the company launched a zinc-coated boron steel product under the trade name HQ1500 ZnX®.

1 Hot press forming involves heating steel blanks to more than 900°C in special temperature- and atmosphere-controlled ovens and then stamping them in water-cooled die-sets. Heating the blanks in this way makes them easier to form and subsequent rapid cooling makes them extremely strong, allowing lighter steels to be used.

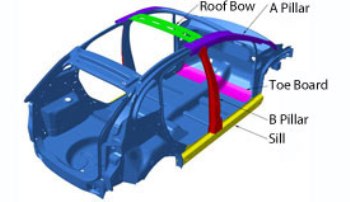

2 Parts such as A-pillar uppers, B-pillars, sills and toe boards.