Feb 19 2015

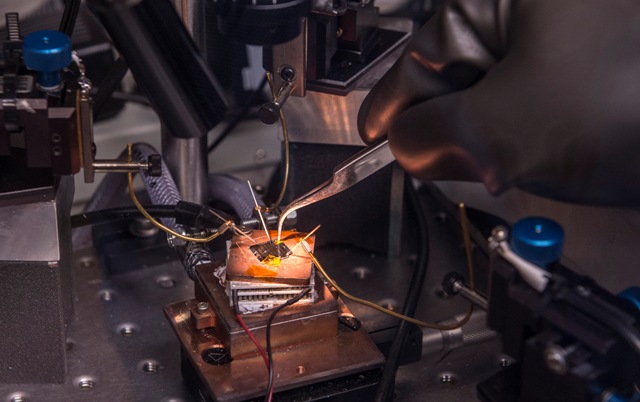

Semiconductor devices like this one now can be joined electronically with a new solder developed by chemistry Professor Dmitri Talapin’s research group at the University of Chicago. Credit: Rob Kozloff, University of Chicago.

Semiconductor devices like this one now can be joined electronically with a new solder developed by chemistry Professor Dmitri Talapin’s research group at the University of Chicago. Credit: Rob Kozloff, University of Chicago.

Professor Dmitri Talapin of the University of Chicago has led a team of researchers who have developed a new method to solder semiconductors.

This study, which Talapin had conducted along with his associates from UChicago, the Illinois Institute of Technology and the Argonne National Laboratory, proposes an innovative method that enables semiconductors to retain their ability to deliver good electronic performance even after being soldered.

“We worked out new chemistry for a broad class of compositions relevant to technologically important semiconductors,” said Talapin, a professor in chemistry.

Semiconductors play an important role in most electronics. They have the ability to conduct electricity and allow generation and control of electric current in a wide range of electronics ranging from solar cells to computer chips.

Talapin had developed compounds along with his associates that could be used for joining together semiconductor pieces. Semiconducting surfaces are very sensitive to structural defects and impurities, and hence engineers have found it difficult to join semiconducting surfaces together.

“If you put two pieces of semiconductor next to each other, each joint will be unique and in most cases will block transport of charges,” Talapin said. “You will not be able to make a reasonably good electronic circuit by simply taking different semiconductor pieces and pressing them against each other as you could do with metals.”

The research team has developed compounds that are composed of cadmium, bismuth and lead. These compounds can be applied in paste or liquid form for joining two semiconductor pieces together by heating them to a temperature of several hundred degrees Celsius. This is considered to be a mild temperature.

“Our paste or our liquid converts cleanly into a material that will be compositionally matched to the bonded parts, and that required development of new chemistry,” Talapin said. “We had to design special molecules that fulfill this requirement so that they do not contaminate the material.” The material decomposes after application as a paste or liquid and forms a seamless joint.

“Dr. Talapin’s work is exciting because its applications are so diverse,” said Eric Ginsburg, assistant director at UChicagoTech, the University’s Center for Technology Development and Ventures.

Cristianne Frazer, a project manager at UChicagoTech, and Ginsburg had helped Talapin earlier in licensing his technologies. In order to establish a strategy to develop the solder material, they are collaborating with investors, industry contacts and Talapin.

The U.S. Department of Energy’s Advanced Photon Source at Argonne which was used in this study played an important role in the success of this project.

“The classical, top-down manufacturing process in the silicon industry does not require soldering,” Talapin said. A large silicon crystal is first created, and then cut, carved and etched into the shapes desired.

Present day mainstream silicon technology is unlikely to be impacted in a major way by semiconductor soldering. However, they could help develop solution-processed, cost-effective semiconductors that are required for entering new markets such as 3-D printing, solar cells, flat panel displays, thermoelectric heat-to electricity generators and printable electronics for the Internet of Things.

Semiconductors have to be assembled from small pieces like Legos for making printable electronics. “It’s like what people call additive manufacturing, when you add things and build from pieces,” Talapin said. “If you want to assemble pieces, you need a solder or glue or connectors.”

Talapin states that 3-D printing was a market that was growing exponentially. “We can 3-D print, to my knowledge, almost any class of materials, but not semiconductors.” The newly developed solder could help address that constraint.

In flat-screen televisions, each pixel is operated by a tiny transistor. Presently, vacuum methods are used for manufacturing these transistors. However they are expected to change to other cost-effective solution-based production methods or printing methods.

The growing network of everyday objects that have the ability to communicate with each other automatically through miniature web servers is considered as the Internet of Things (IoT). The everyday objects include cars and traffic lights.

Tiny sensors can also be incorporated in bridges, buildings and other structures, which would provide a warning about any structural failure or cracks in those structures. In these devices, electric current is required for receiving, processing and transmitting the information within the IoT network. Here, semiconductors will be required for converting the heat or sunlight into the electrical current.

“That requires very inexpensive semiconductors for electronic circuits and devices that come essentially at the price of a postage stamp,” Talapin said. "Printing electronics in a way similar to printing postage stamps. It is a chemistry problem to find the right “inks” for this purpose," he said. “Right now postcards and magazines are simply colorful, but there’s nothing that precludes them from being colorful and electronically active, so that as ink dries it forms a film that can conduct charges. It’s not sci-fi these days.”

The solar cells market is highly profitable and competitive. This increases the necessity of enhancing solution-process methods to manufacture semiconductors.

“Solution-processed semiconductors is a huge field. We definitely have hundreds of competitors, both in academic settings and in companies,” Talapin said. “It’s a very competitive area because it’s now on the final approach to big money.”

In solution-processed semiconductors, the new semiconductor soldering method has set a new record for mobility of electrons, which is nearly 10 times faster than the previous record. Electron mobility is a measure of how swiftly electrons can move through materials.

“It’s mind-blowing,” Talapin said.

The research team has published their study entitled “Composition-matched molecular ‘solders’ for semiconductors” in the journal, Science.