The formation of wrinkles is a common process which anyone who has taken a bath or has been in water for a long period of time will have observed. When a material made of layers, which has properties which are not uniform, is subjected to shrinking or stretching, it tries to form patterned surfaces, which causes the different layers shrink or stretch in different ways. This leads to the formation of wrinkles, delaminated buckles, folds or creases.

This new study conducted at MIT has created a unified model that accurately demonstrates the properties of the individual layers, the manner that they are bonded to one other and this helps to determine the precise form of resultant texture.

The patterning process developed by the team applies to all types of wrinkles including a pumpkin’s ridged skin, a tree bark’s buckling, an aging face’s wrinkles and the folds on a brain’s surface.

The researchers state that determining the factors which lead to production of these patterns could help to design synthetic materials which posses the types of surface required for specific applications such as improved water-shedding properties or traction. This study could also help to gain better knowledge about biological processes such as growth of organs, microbial colonies, animals and plants.

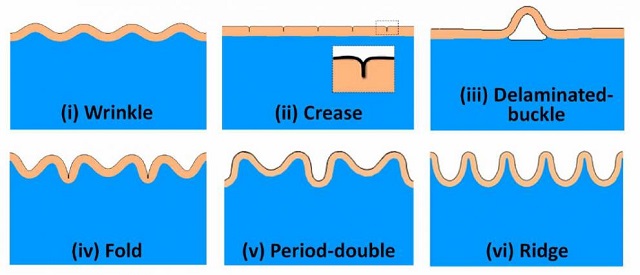

“We propose a systematic approach,” says Zhao. The researchers commenced their work by classifying the various patterns into particular categories, which included wrinkles, folds, ridges, period doubles, delaminated buckles and creases.

Wang explains that when wrinkles are seen in cross-section they have a sinusoidal curve shape, which is a comparatively uniform wavy shape. 'Creases' are similar to a brain’s surface and have sharp indentations. 'Delaminated buckles' form when the different layers begin to come apart. Shapes having comparatively spaced-out and narrow peaks are 'ridges'.

Schematics of growth-induced surface instabilities: (i) wrinkle, (ii) crease, (iii) delaminated-buckle, (iv) fold, (v) period-double and (vi) ridge. Image Credit: Zhao and Wang | MIT

Each of these forms was then described as a different 'phase' and the researchers then produced a 3D phase diagram which demonstrated how the three basic characteristics of the layered material led to different shapes. These characteristics are the rigidity, the tightness of bonding and the shrinkage or expansion.

“We can quantitatively predict which state a surface will fold into, so you can design the pattern you want.” These same principles “apply to various length scales, from very small to very large,” added Zhao.

Zhao had previously explored using patterning mechanisms for materials design, such as using gphene in a crumpled form to create flexible supercapacitors and batteries.

“Now, we can guide the design of new patterns and functions,” Wang said, “by going to a set of parameters predicted by the model.”

The researchers compared the predictions of their model to different types of materials and results derived from them. They found that the predictions matched with the experimental data. “The surprising thing is, with so many complicated shapes, now you can just use one system, one understanding” to explain variations, Zhao said. “This is the simplest model that explains all these patterns.”

The team anticipates that this model would help understand aging and growth patterns in biological organisms, design of materials for cell cultures, disease treatment, flexible electronic materials, water shedding and biofouling.

This is “very impressive work,” says Yonggang Huang, the Joseph Cummings Professor of civil and environmental engineering at Northwestern University who was not involved in this research. “This is the first systematic study of the competition among different types of surface-instability patterns,” he says.

“Many modern technologies, such as stretchable and flexible electronics, harness surface-instability patterns to achieve extraordinary functions. Such a phase-diagram approach will help to develop a predictive model to facilitate the advancement of these technologies.”

This research has been published in the Scientific Reports journal.