Mar 12 2015

Researchers at the Université Pierre et Marie Curie in Paris and UCLA Henry Samueli School of Engineering and Applied Science have developed a method of manufacturing strong and highly durable glass.

The research could pave the way for more long-lasting materials in applications such as windows, fiber optic cables and display screens.

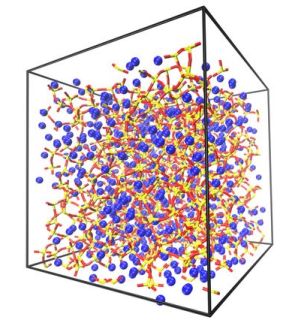

Rendering of the molecular structure of sodium disilicate glass. Researchers have identified a way to produce glass that is more durable. (Credit: Courtesy of UCLA Engineering)

Rendering of the molecular structure of sodium disilicate glass. Researchers have identified a way to produce glass that is more durable. (Credit: Courtesy of UCLA Engineering)

Glasses are liquids that reach its stable “frozen liquid” state upon cooling during the manufacturing process. However, over the years, the glass tends to wear and is exposed to varying temperatures. This causes a change in its shape as it continues to "relax".

The optimal conditions for the development of durable glass and cement were identified by Matthieu Micoulaut, a professor of materials science at the Université Pierre et Marie Curie, and Mathieu Bauchy, an assistant professor of civil and environmental engineering at UCLA.

The researchers performed computer simulations to investigate the molecular dynamics of materials used for making glass. They also determined a pressure range suitable for achieving “thermal reversibility" where a material retains its original properties even after exposure to varying temperature.

“The key finding is that if you use specific conditions to form glass — the right pressure and the right composition of the material — you can design reversible glasses that show little or no aging over time,” Bauchy said.

Furthermore, Bauchy compared the molecular structure of glass to the metal framework of the Eiffel Tower. He said that the rigidity and strength of the structure depend on the angles at which beams and crossbeams are linked. The new process tends to improve the angles at which the connectivity occurs, resulting in a stronger material.

The research could also reduce the generation of greenhouse gases. American Ceramic Society states that the production of concrete and cement contributes to nearly 5% of all greenhouse gas generation.

“The smaller the quantity of material we use to rebuild deteriorating structures, the better it is for the environment,” said Bauchy, whose research focuses on forging stronger ties between fundamental physics and engineering to design better, more sustainable materials.

The research was published in the Nature Communications journal.