Mar 13 2015

The continuous evolution of the aviation industry allows it to create lighter aircraft, minimize fuel consumption and associated emissions, and establish more-efficient recycling systems to allow reusing of the valuable materials used in aircraft building.

This is the research context in which the European SENTRY project, a Basque IK4 R&D Alliance-led initiative, is positioned.

The European SENTRY project is part of the Clean Sky initiative, which is focused on bringing in major step changes concerning the environmental impact of the aviation industry.

The Clean Sky program is a public-private partnership between the aeronautical industry and the European Commission.

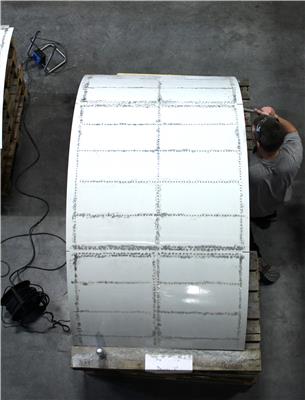

The European SENTRY project focuses on performing differentiated recycling of alloys used in the manufacture of aircraft test panels for construction of a fuselage.

By this way, the used materials do not get classified as lower added value products and can be reused in their original applications without compromising the properties.

Although aircraft test panels are produced from different materials, the current recycling process is performed in a collective manner, making the recycling of raw materials less efficient.

The expert went on to say that the recycling process proposed allows separate recovery of each of the aluminum alloys utilized for panel production.

It’s about closing the circle so that the materials can go on being incorporated into the same application and achieve the highest degree of recycling.

Sixto Arnaiz, Project Coordinator

As these alloys are so specific, they should not be combined with other materials in order to maintain their properties, especially in the case of alloys composed of lithium. Lithium is a highly reactive material and imparts the lightweight quality to the alloys.

In addition, several major companies are actively involved in the European SENTRY project. Some of the companies include Dassault Aviation, a French aviation company; AELS, a Dutch company specializing in end-of-life aircraft recycling; Constellium, an international company producing aluminum products; and IAI, an Israel-based company. The specification and methodological analysis phase of the project has been successfully concluded.

We’ve done the theoretical part and what remains now is to put it into practice and check that what have been specified functions well.

Sixto Arnaiz, Project Coordinator

According to Arnaiz, the design and integration of innovative solutions such as lighter panels or new alloys in the aviation industry has to address the technical and environmental prerequisites – a key objective of the Eco-design area in the Clean Sky initiative.

The European Commission provides 75% of the total budget of the project worth €300,000 through the 7th Framework Programme. The projects started in 2014 with duration of 16 months, and conclusions are expected to be presented at the end of July 2015.