May 20 2015

Image Credit: FZ Jülich

Image Credit: FZ Jülich

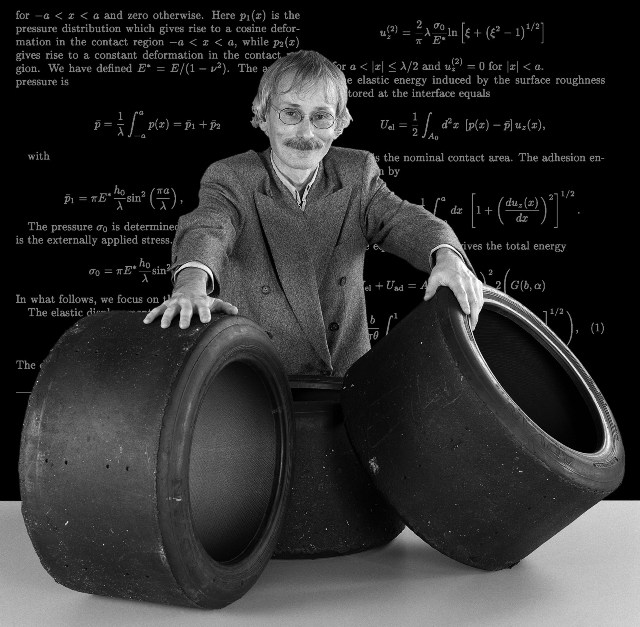

Bo Persson and his colleagues at the Jülich Research Center, have discovered new temperature and velocity-dependent properties of rubber friction on asphalt.

They have uncovered new atomic-level information into the process that takes place when rubber slides across a surface such as asphalt. This discovery strengthens the belief that a critical friction component originates when the process of sticking of rubber molecule chains to the road, followed by stretching, and then releasing takes place repeatedly.

When objects slide across a surface, friction is the force that slows them down. In vehicles, friction is the force that helps stop the vehicle when brakes are applied. Though its importance is known, the science behind how friction works at the atomic and molecular level is not known.

"Rubber friction is an extremely interesting topic and of extreme practical importance, for tires and very many other applications," Persson said. Persson has been studying the phenomena of friction for over 20 years. Tire companies could benefit from more knowledge about friction, which would help them to choose treads and seasonal rubber materials more efficiently.

"Currently tire companies must manufacture entire tires and test each one," Persson said. Tire companies could save considerable money and time if they had a model that could help them predict the behavior of the material beforehand.

Researchers believe that at the atomic level, a major factor behind rubber friction is the rubber’s deformation that takes place when rubber gets pressed against rough points that exist on the road. When the tire gets pressed and squished against the asphalt’s tough grains, internal motion that takes place as waves pushes around the rubber molecules.

The energy gets dissipated as the waves move. The road’s texture influences the quantum of energy that gets lost. Roads with smooth surfaces cause less friction when compared to roads that have a rougher surface.

Viscoelasticity is a property of rubber that describes deformation of the material when it gets pushed. This property also contributes to loss of energy. Persson states that the industry typically uses only viscoelasticity for estimating rubber friction, however, when considered in terms of real-world performance it has not been found satisfactory.

Another factor, called as shearing also contributes to friction. This is a dragging movement and takes place when the rubber gets dragged parallel to the road surface.

Various origins for friction can be created by shearing. This includes binding of rubber molecules with the surface of the road; hard filler products used in the rubber; cracks developing in the rubber; other wear effects taking place in the rubber; foreign particles or fluid that get filled in gaps and act as a barrier between the road and the rubber.

Persson has been trying to develop equations that take into consideration the contributions of both shear and viscoelastic properties. Viewing the contact area between the road surface and rubber block on a nanoscopic or microscopic scale would reveal rough valleys and peaks between the surface and the block. For a complete set of tyres, the actual area of contact is just in the order of a square centimeter.

The predictions of this theory were tested for actual area contact and viscoelastric friction coefficient, and the findings were found to agree with numerical simulations.

Leonardo da Vinci had devised a set-up for measuring friction of various types of rubber compounds when they were dragged across a sandpaper surface, and two asphalt surfaces. This experiment was done with three rubber compound types and at different background temperatures.

Slow sliding speeds of less than 1mm/s were tested. This slow speed would prevent frictional heating, which could have affected the rubber’s viscoelastic properties.

"Rubber friction is a complex topic and any theory for rubber friction should first be tested for the most simple situation," the authors write in their paper.

The experimental data and Persson theory’s frictional shear-stress law was found to match. The contribution of shearing to rubber friction changed with velocity and temperature in a manner which was different to the way in which viscoelastic property contributed to friction. This showed that depending on only viscoelastric friction coefficients could lead to wrong conclusions.

The attachment, stretching, breaking free, and reattaching of rubber molecules to the road, could be due to friction’s shearing component. The data collected in this study provided proof to support this adhesive friction model, because the theory and the velocity and temperature- dependent properties matched.

At lower temperatures when the bonds formed slower, and at higher velocities when the rubber moved very rapidly that prevented the molecules from being given a chance to stick, the adhesive friction was found to decrease more rapidly at lower temperatures.

The initial results obtained from this study are based on dry, clean surfaces. When the road surface is wet, a very thin water film at characteristic slip velocities is formed when braking is done. This would prevent binding of the rubber molecules to the asphalt. In this scenario, the viscoelasticity must be the major contributor to the friction force, as the contribution of adhesiveness may be insignificant.

The researchers have published their findings as an article titled, "Rubber friction on road surfaces: experiment and theory for low sliding speeds," in the Journal of Chemical Physics.