Nov 1 2016

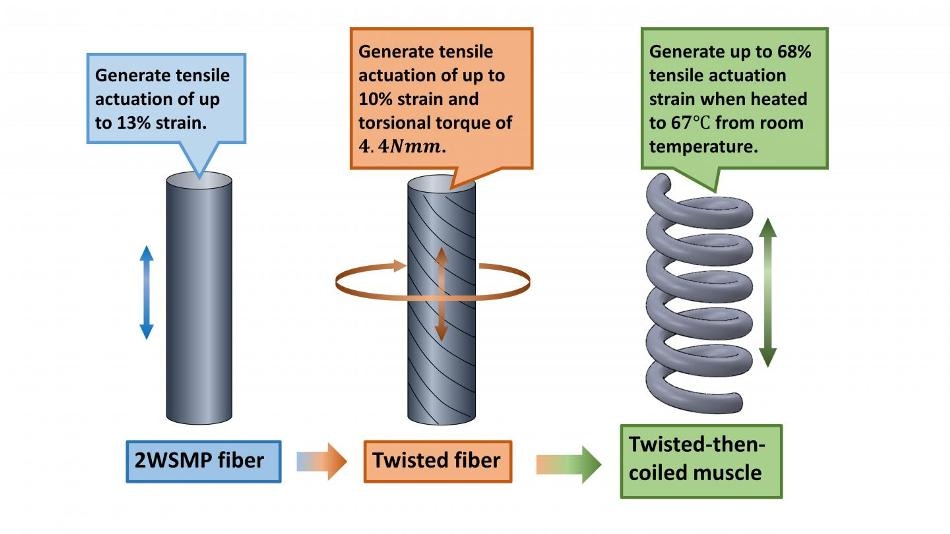

This is the fabrication procedure and actuation of coiled artificial muscle based on two-way shape memory polymer fiber. (CREDIT - Louisiana State University)

This is the fabrication procedure and actuation of coiled artificial muscle based on two-way shape memory polymer fiber. (CREDIT - Louisiana State University)

Artificial muscles made significant gains when a literal twist in the development approach revealed the tensile, or stretchy, abilities of polymer fibers once they were twisted and coiled in the form of a spring-like geometry.

Just like the powerful climbing tendrils of cucumber plants, this unique geometry provides the coil with a flexing motion when the fiber material shrunk, a reaction that can be controlled with heat. Researchers have now enhanced these tensile characteristics even further by concentrating on the thermal properties of the polymer fiber and on the molecular structure that uses the chiral configuration in the best way possible.

In the recent cover article featuring in Applied Physics Letters, from AIP Publishing, Guoqiang Li and his team in the Department of Mechanical and Industrial Engineering at Louisiana State University, demonstrate the how they produced a new fiber that provides higher tensile stroke and is actuated or triggered at temperatures exceeding 100°C cooler than its predecessors.

We analyzed the principle behind why the polymer fiber, through twisting and coiling, can behave so remarkably.

Guoqiang Li, Louisiana State University

According to Li they discovered two driving factors: the negative coefficient of thermal expansion (NCTE) and the untwisting nature of the fiber during actuation. The two-way shape memory polymer (2W-SMP) fiber developed by Li and his team addressed both of these factors.

The untwisting process that causes this chiral-upon-chiral architecture to flex and contract was focused on by Li's group at the molecular level. The reversible responses of the 2W-SMP polymer that make them ideal come from a stable molecular network of chemical cross links.

The network provides chains of oriented molecules in the polymer whose melting and recrystallization results in the development of the significant memory characteristics of the fiber.

The reversible crystallization/melt transition also provided improved thermal expansion features in comparison to conventional fibers, where actuation comes from the intrinsic contraction of the polymer components in the existence of heat (and relaxation when the heat is removed).

The 2W-SMP fiber illustrates thermal expansion/contraction, which is an order of magnitude grater than the NCTE of its predecessors.

By looking into these two attributes, the fibers Li created and analyzed in their twisted-then-coiled muscle configurations displayed greater tensile actuation, but they also lowered the temperature required to actuate these artificial muscle fibers.

The actuation temperature is very high in the polymer fibers used previously, for example they can go to 160°C. For some applications, like medical devices, [the] actuation temperature is too high. So you need to find a way to lower it.

Guoqiang Li, Louisiana State University

That is precisely what the team did, reporting highest actuation temperatures of 67°C.

The low temperature is important when considering a number of applications linked to human body temperature outside of just medical devices, including self-healing materials and breathable textiles whose structures adapt to environmental changes.

Li and his team continue to encounter challenges with the performance of the fiber's specific work as well as efficiency in transforming thermal energy into actuation, and seek to overcome these problems in future work. One possible approach could be to add conductive reinforcement into the material using carbon nanotubes.

Our polymer is very soft. So by adding some reinforcement, like carbon nanotubes, we'd have two benefits. The first one makes it into a conductor, that means we can also use electricity and have it trigger the muscle behavior. The other is that the carbon nanotube will increase the stiffness.

Guoqiang Li, Louisiana State University

Better stiffness means better energy storage for the fiber, which then boosts the energy conversion efficiency.