Mar 8 2017

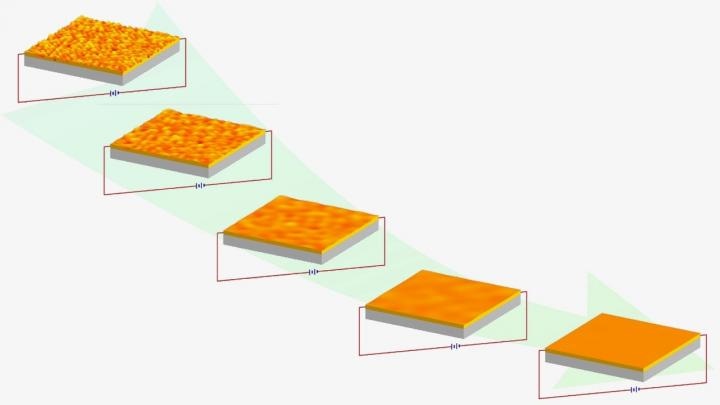

Sequence of snapshots from a computer simulation of electric-field-driven morphological evolution of a copper thin film, demonstrating current-induced smooth surface. Credit: Du and Maroudas

Sequence of snapshots from a computer simulation of electric-field-driven morphological evolution of a copper thin film, demonstrating current-induced smooth surface. Credit: Du and Maroudas

Surface roughness reduction is very important for fundamental surface physics and while fabricating optical and electronic devices.

When transistor dimensions inside integrated circuits continue to shrink, smooth metallic lines are needed to connect these devices. If the surfaces of these small metal lines are not smooth enough, it significantly reduces their ability to conduct thermal and electrical energy, and lowers their functionality.

Now, a team of engineers from the University of Massachusetts Amherst report an advance in the form of modeling results that confirmed electrical surface treatment of conducting thin films as a viable physical processing strategy for surface roughness reduction. The findings are published this week in Applied Physics Letters, from AIP Publishing.

We've been thinking hard about this roughness problem for many years, since showing that electric currents can be used to inhibit surface cracking. So as soon as we developed the computational tools to attack the full film roughness problem, we got to work.

Dimitrios Maroudas, Professor, University of Massachusetts

The team’s research focused on using a copper film on a silicon nitride layer in order to quantify the model parameters for their simulations and compare them with existing experimental findings, which the researches were able to reproduce.

"Surface electromigration is the key physical concept involved," Maroudas explained. "It's the directed transport of atoms on the metal surface due to the so-called electron wind force, which expresses the transfer of momentum from the electrons of the metal moving under the action of an electric field to the atoms (ions) -- biasing atomic migration."

Imagine it as similar to the diffusion of ink in flowing water.

Electromigration's role in the transport of surface atoms is analogous to that of convection due to flow on the transport of ink within the water. The combined effects of a well-controlled applied electric field and rough surface geometry drive the atoms on the metal surface to move from the hills of the rough surface morphology to the neighboring valleys, which eventually smooth away the rough surfaces.

Dimitrios Maroudas, Professor, University of Massachusetts

In particular, this research is significant within the microelectronics realm, because it determines the electrical treatment of metallic (conducting) films as a possible physical processing method for reducing surface roughness.

"Our approach is qualitatively different than traditional mechanical polishing or ion-beam irradiation techniques," said Lin Du, co-author and a doctoral student working with Maroudas. "It directly influences the driven diffusion of surface atoms precisely, which affects surface atomic motion and enables a smooth surface all the way down to the atomic level."

The needed electric field action can be easily controlled macroscopically by simply selecting a direction, modify the voltage, and flip a switch "on."

While studying the phenomenon, we discovered that a sufficiently strong electric field can bring the metallic surface to an atomically smooth state. The required electric field strength depends largely on the field direction and surface material properties of the metallic film -- such as film texture and surface diffusional anisotropy, because in surfaces of crystalline materials diffusion is faster along certain preferred directions.

Lin Du, Doctoral Student, University of Massachusetts

A true irony here is that "electromigration is best known for its damaging effects within metallic interconnects -- underlying crucial materials reliability problems in many generations of microelectronics," Maroudas said.

As far as applications, since this work determines the principles to produce smoother conducting material surfaces, "it can be used for fabricating and processing nanoscale-thick metallic components within electronic and optical devices, which require atomic-scale smoothness," Maroudas said. "The ability to reduce the surface roughness of metallic components, such as interconnects within integrated circuits, will significantly improve their performance as well as durability and reliability."

What's the next step for the engineers?

We're currently exploring how the effectiveness of the method depends on the metallic film texture (or surface crystallographic orientation), the film's wetting of the substrate, and the electric field direction with respect to certain surface crystallographic directions.

Dimitrios Maroudas, Professor, University of Massachusetts

The team's immediate goal is "to optimize the electrical treatment technique, and to identify the conditions for minimizing the required electric field strength, as well as the cost of applying this technique," he added. "Our next natural step should be a partnership with an experimental laboratory with the proper expertise to carry out tests that will help us move from proof of concept to an enabling technology."