Jun 1 2017

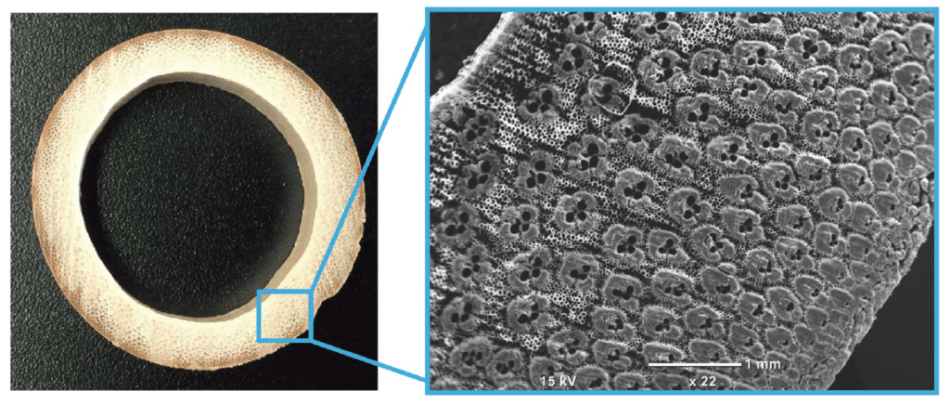

The cross section of a wild moso bamboo Phyllostachys pubescens. Fibers (vascular bundles) surrounding the heart-shaped black openings have a denser distribution toward the outer part. (Sato M., et al., PLOS ONE, May 3, 2017)

The cross section of a wild moso bamboo Phyllostachys pubescens. Fibers (vascular bundles) surrounding the heart-shaped black openings have a denser distribution toward the outer part. (Sato M., et al., PLOS ONE, May 3, 2017)

A recent finding that throws light on biomimetic approaches in the development of materials refers to the optimization of spatial distribution of fibers in hollow bamboo cylinders in order to reinforce flexural rigidity.

Bamboo, both tough and light, is extensively used as a functional and natural material in Japan and several other Asian countries. Bamboo’s hollow structure enables it to be light and also it to grow faster with tiny amounts of woody parts and expose itself to sunlight above other trees. However, by being light, bamboo indeed becomes vulnerable to powerful crosswinds and can also fail to support its own weight. The woody parts of bamboo are reinforced with thin but tough fibers (vascular bundles) in order to overcome this limitation. Each fiber is considered to be as rigid as steel.

An analysis of a cross section of bamboo revealed the unequal distribution of fibers in the woody parts. The density of the fibers progressively turns out to become thicker from the inner to the outer surface, pointing out that the outer parts are stronger than the inner parts based on a mechanical perspective. This indeed is reasonable since more force is received by the outer parts when the cylinder is bent.

Researchers from Hokkaido University, Prefectural University of Kumamoto and the University of Yamanashi determined the relationship between the distribution of the reinforcing fibers in a culm and the flexural rigidity of the culm by comparing the data obtained from the real bamboo’s fiber distribution to the theoretically established optimal fiber distribution.

The researchers were surprised to observe that the real bamboo data almost displayed the same fiber distribution as the one with the theoretical, optimal fiber distribution. The real fiber distribution corresponded to the theoretically derived quadratic form for gradient distribution near the root of the culm, where an increased number of fibers are present. The experimental data matched the linear distribution calculated based on the theory near the tip of the culm, where there are very few fibers than near the root.

As an outcome, the researchers studied that bamboo accurately alters the distribution of fibers, maximizing flexural rigidity with the lowest volume of wood material possible. Thus, the mechanical theory employed in this study can also be applied to various other hollow cylinders in order to determine the gradient distribution that can help in optimizing flexural rigidity.

Our study could help develop advanced materials by mimicking the bamboo model for its lightness and toughness. Imitating the systems of animals and plants which have survived harsh conditions, an approach called biomimetics has proved successful in solving many problems in the development of materials in recent years.

Motohiro Sato, Hokkaido University.