Oct 25 2017

The Science

Whether it is smaller computer chips or better solar panels, new technologies demand advanced semiconductors. The existing standard approach used for fabricating semiconductor alloys incorporates materials with similar crystal structures and mostly results in materials that are poorly mixed. That is, the materials are vulnerable to composition fluctuations.

Scientists now have a new way to produce well-mixed semiconductor alloys by merging materials with different crystal structures. The result? They bend the laws of thermodynamics in order to reduce or eradicate the driving force for such fluctuations. The new alloys are capable of being stable over extensive ranges of composition and may also have desirable properties.

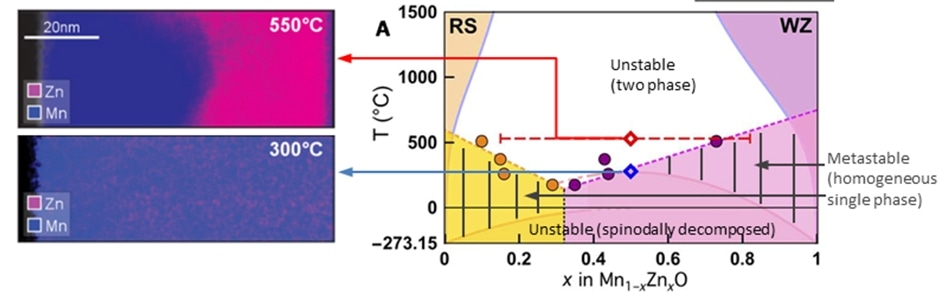

Using computational methods, scientists showed how to mix manganese oxide and zinc oxide to create an alloy with a “sweet spot” (right, blue diamond) where the elements are uniformly mixed (lower left). When synthesized at a higher temperature (right, red diamond), the same material lacks homogeneity (upper left). Credit: Image courtesy of the National Renewable Energy Laboratory

Using computational methods, scientists showed how to mix manganese oxide and zinc oxide to create an alloy with a “sweet spot” (right, blue diamond) where the elements are uniformly mixed (lower left). When synthesized at a higher temperature (right, red diamond), the same material lacks homogeneity (upper left). Credit: Image courtesy of the National Renewable Energy Laboratory

The Impact

The team’s work demonstrates how to alloy materials with varied crystal structures in order to produce new semiconductors. Being able to homogeneously merge two materials opens up much wider “design spaces” for customizing materials. With this technique, scientists will thus be able to modify material properties.

Summary

Composition and structure control the properties of materials. For semiconductors, the isostructural alloying of two “end point” phases with the same crystal structure has been the traditionally successful approach for such control. However, the potential to synthesize and then tune these alloys can be controlled by solubility limits, spinodal decomposition or weak composition dependence of the properties. Researchers have demonstrated a new approach for such control: the heterostructural alloying of two “end point” phases with varied crystal structures. By combining computational calculations and combinatorial thin-film phase-equilibria experiments, the researchers were able to demonstrate that a prototypical alloy (Mn1-xZnxO) displays a dramatically widened window within which binodal decomposition is suppressed and spinodal decomposition is impossible. In this new class of alloys, the metastable window for compositionally homogeneous single-phase alloys is wider, and the properties (for example, optoelectronic, piezoelectric, electronic, ferroelectric) are capable of changing in a discontinuous or highly non-linear fashion near the critical composition, offering two new routes to materials design.