Dec 8 2017

Nature stimulates innovation. An international research team led by researchers at Technion - Israel Institute of Technology, along with ESRF -the European Synchrotron, Grenoble, France- scientists, have seen how a brittle star can form material like tempered glass underwater. Their findings have been published in Science and may open new bio-inspired paths for strengthening brittle ceramics in several applications that span from automotive turbochargers to optical lenses and even biomaterial implants.

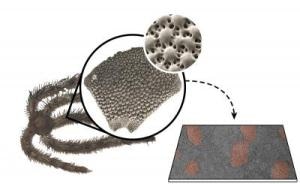

Schematic illustration showing the various scales, from the brittle star organism, the arm plate, the lenses and the TEM image showing the coherently aligned nano precipitates within the lattice. CREDIT: Iryna Polishchuk

Schematic illustration showing the various scales, from the brittle star organism, the arm plate, the lenses and the TEM image showing the coherently aligned nano precipitates within the lattice. CREDIT: Iryna Polishchuk

An beautiful, brainless brittle star that exists in coral reefs has the clue to super tough glass. Numerous focal lenses are found on the arms of this creature, which is an echinoderm known as Ophiocoma wendtii. These lenses, made of chalk, are sturdy and accurate, and the deciphering of their crystalline and nanoscale structure has engaged Boaz Pokroy and his team, from the Technion-Israel Institute of Technology, for the last three years. Thanks to research completed on three ESRF beamlines, ID13, ID22, and ID16B, among other laboratories, they have found out the unique protective mechanism of extremely resistant lenses.

For example take tempered glass, it is produced by applying compressive pressure on the glass which compresses it and leaves it more compact than in its natural state. Glass tempering is done by quickly heating and then quickly cooling the material. In this process, the outside of the material cools more rapidly than the inside and thus compresses the inside. Ophiocoma wendtii lenses are formed in the open sea, at room temperature, in contrast to tempered glass. "We have discovered a strategy for making brittle material much more durable under natural conditions. It is 'crystal engineering' and tempering without heating and quenching - a process that could be very useful in materials engineering", explains Pokroy.

The development of calcite lenses was discovered due to a long series of experiments at the ESRF and the Titan transmission electron microscope at the Technion. "When we first came to the ESRF we didn´t expect our research to reach these results", says Pokroy. The team came first to ID22, where they employed powder X-ray diffraction to see into the material in a powder form while heating it. "We understood that we had nanodomains after this experiment, so we did some transmission electron microscopy at home, then came to ID13 to map the nanodomains and finally to ID16 to do tomography on how the different particles arrange themselves in different layers", he adds.

The team, which includes researchers from the University of Wisconsin (US), the Natural History Museum of Los Angeles county (US), the University of Trento (Italy) and the Charité Hospital in Berlin (Germany), discovered that the vital stage in the process of lens formation is the changeover from the amorphous phase - the phase between liquid and solid - to the crystalline phase. At this stage, calcite nanoparticles, which are abundant in magnesium and characterized by a comparatively low density, separate from the rest of the material. The variance in concentration of magnesium in the calcite particles causes different degrees of density, hardness, and pressure in various regions of the material. Magnesium-rich particles press on the inner part of the lens as it crystallizes and "temper" it into a clear and hard crystalline material.

"Nature exhibits tremendous creativity in improving the organism's abilities in various contexts such as strength, sensing, and self-defense. Here, too, in the process of creating hardy and precise transparent lenses, we see tremendous efficiency in the use of existing raw materials under conditions in the natural environment".

Engineers at present can use this recently discovered biostrategy in strengthening and toughening synthetic ceramic materials in a range of applications that span from optical lenses to automotive turbochargers and even biomaterial implants.