Jan 30 2018

The correct mix of hydrogen bonds in cement and polymer composites is vital for making tough, strong and ductile infrastructure material, according to Rice University scientists, who wish to imitate the mechanics of mother-of-pearl and similar natural composites using synthetic materials.

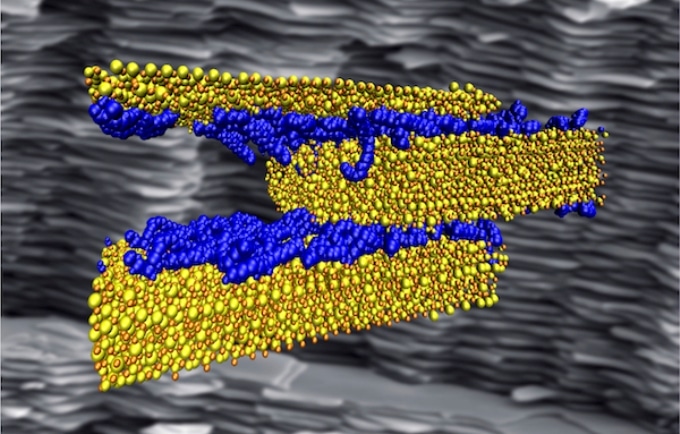

Rice scientists probing the interfacial interactions of polymer (blue) and cement (yellow), discovered the right mix of hydrogen bonds is critical to making strong, tough and ductile composite materials for infrastructure. Computer simulations like that in the illustration measured the strength of the bonds as hard cement slides past the soft polymer in a layered composite, which mimics the structure nacre, seen in the background. (Image credit: Probhas Hundi/Multiscale Materials Laboratory)

Rice scientists probing the interfacial interactions of polymer (blue) and cement (yellow), discovered the right mix of hydrogen bonds is critical to making strong, tough and ductile composite materials for infrastructure. Computer simulations like that in the illustration measured the strength of the bonds as hard cement slides past the soft polymer in a layered composite, which mimics the structure nacre, seen in the background. (Image credit: Probhas Hundi/Multiscale Materials Laboratory)

Seashells developed from mother-of-pearl, aka nacre, attain their outstanding properties from overlapping micron-sized, mineralized plates held together with the help of a soft matrix. This structure can be approached by polymer and cement composites that may, for example, make improved earthquake-resistant concrete, according to Rouzbeh Shahsavari, an assistant professor of civil and environmental engineering.

The Rice lab ran more than 20 computer simulations of how cement and polymer molecules come together at the nanoscale and what actually drives their adhesion. The researchers demonstrated that the proximity of hydrogen and oxygen atoms is the vital factor in developing a network of weak hydrogen bonds that connects hard and soft layers. Common polyacrylic acid (PAA) was found to be best at binding the overlapping layers of cement crystals along with an optimal overlap of almost 15 nm.

This information is important to make the best synthetic composites. A modern engineering approach to these materials will have a large impact on society, especially as we build new and replace aging infrastructure.

Rouzbeh Shahsavari, Assistant Professor of Civil and Environmental Engineering

The lab’s results are featured in Applied Physical Letters.

While engineers comprehend that adding polymers enhances cement by blocking the damaging effects of “aggressive” ions that attack its pores, details about how the materials interrelate at the molecular scale have remained unknown, Shahsavari stated. To find out, the researchers modeled composites with polyvinyl alcohol (PVA) and PAA, both soft matrix materials that have been employed for improving cement.

They learnt that the two different oxygen atoms in PAA (as opposed to one in PVA) permitted it to receive and then donate ions as it fused with hydrogen present in the crystals of tobermorite cement. Oxygen in PAA comprised of eight ways to bond with hydrogen (six for PVA) and could also partake in salt bridging between the cement and polymer, which makes the bonding network much more complex.

The researchers succeeded in testing their simulated structures by sliding layers of cement and polymer against each other, discovering that complexity permitted the bonds between PAA and cement to break and then reconnect more often as the material was stressed, which considerably increases its toughness, the potential to deform without fracturing. This permitted the researchers to establish the optimum overlap between cement crystals.

In contrast to the common intuition that hydrogen bonds are weak, when the right number of them — the optimum overlap — cooperate, they provide sufficient connectivity in the composite to confer high strength and high toughness. From an experimental standpoint, this can be done by carefully tuning and controlling the addition of the polymers with the right molecular weight while controlling cement mineral formation. Indeed, a recent experimental paper by our colleagues showed a proof of concept toward this strategy.

Rouzbeh Shahsavari, Assistant Professor of Civil and Environmental Engineering

The research was supported by the National Science Foundation (NSF). Supercomputing resources were supplied by Rice’s NSF-supported DAVinCI supercomputer directed by the Center for Research Computing and acquired in partnership with Rice’s Ken Kennedy Institute for Information Technology.