Apr 24 2018

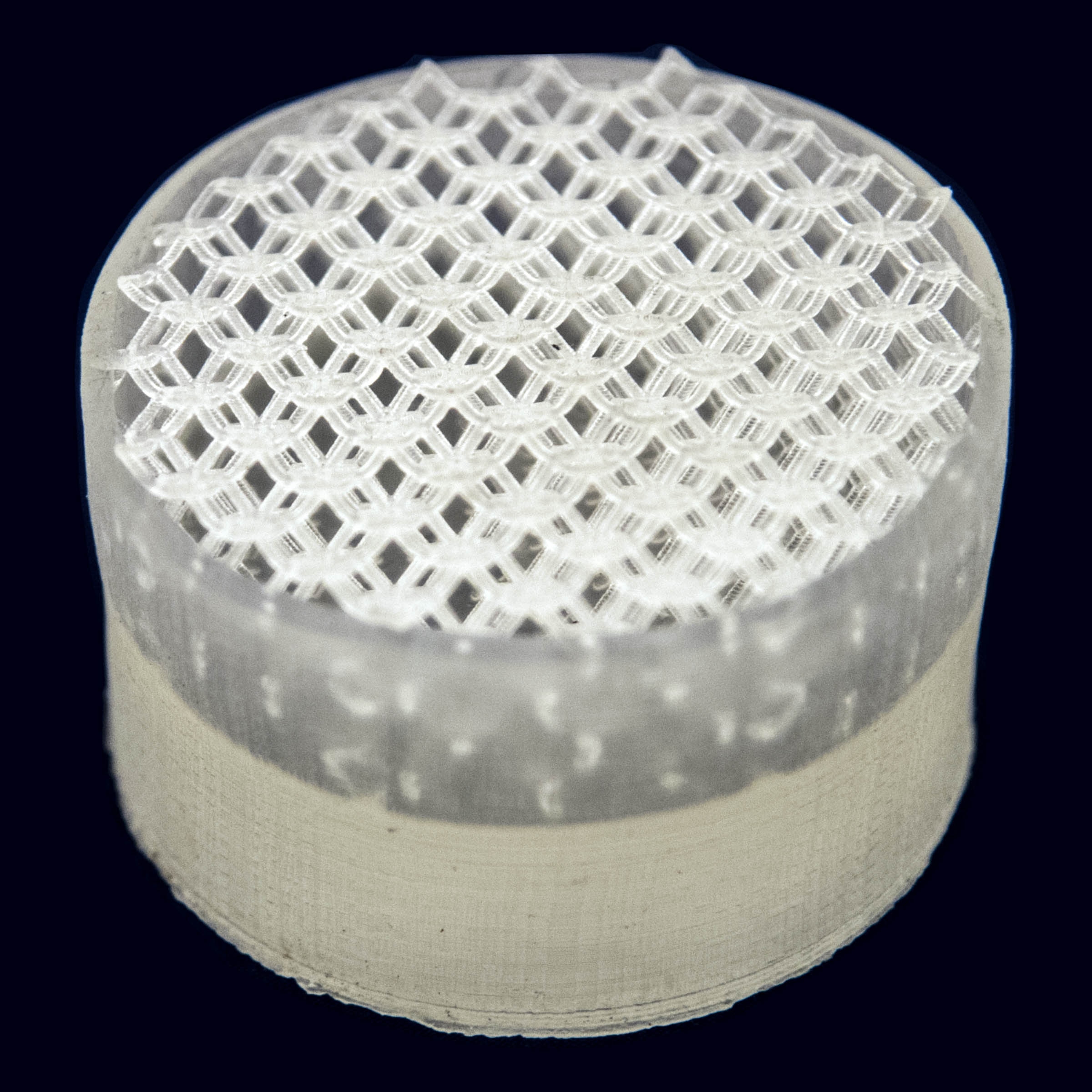

April 24, 2018 | Dallas, TX – Adaptive3D Technologies introduced the world's highest-strain 3D-printable photopolymer today at RAPID + TCT 2018. ToughRubber 30.450 is a material that strains to 450%, 115% higher than the nearest competitor. Throughout 2018 Adaptive3D will launch a series of leading rubber-like 3D printable materials that reshape the Additive Manufacturing landscape by delivering production-quality performance to product teams and manufacturing groups around the world.

The annual market for synthetic rubber is an estimated $45 billion globally with products like shoes, ear buds, tires, seals, connectors, gaskets, and grips. The companies that lead in these areas have long sought to leverage the game changing benefits of 3D printing, such as customization, complex shapes and distributed automated production. However, despite great advances over the past 25 years, product groups around the world are still unable to additively manufacture rubber-like parts with the high strain, the high strength, and the range of durometer that traditional rubber materials offer.

"The ToughRubber family is the solution for those looking for the highest performing rubber-like 3D printable materials" said CEO Walter Voit, PhD. He went on to say that "Over the coming 18 months, Adaptive3D will roll out a series of leading rubber-like products beginning with the world's highest strain 3D printable photopolymer ToughRubber 30.450."

Rubbers and silicone rubbers are very unique materials with a broad range of capability. However, most rubbers are tough and will exhibit high strain along with flexibility. There are currently few 3D printable photopolymers on the market capable of such performance. ToughRubber is true to its name with toughness measured at 30 MJ/m³ as a result of an ultimate tensile strength of 17 MPa and maximum strain of 450%.

Adaptive3D also introduced a prototyping material called ToughPoint 10.20 and both materials were available for viewing and demonstration at booth #2529. RAPID + TCT is an annual event produced by SME and is being held at the Fort Worth Convention Center.

About Adaptive3D Technologies

Adaptive3D is the premium additive manufacturing polymer resin supplier. The company has a mission to enable high volume additive manufacturing through optimized materials. Adaptive3D offers leading additive manufacturing polymer resins and specialty polymers to a range of industries around the world. In particular the company leads in the area of rubber-like 3D printable materials, tough damping materials, and low-cure stress photopolymers.