Freeman Technology is pleased to announce the release of ‘Developing a Design Space for a Die Filling Operation'.

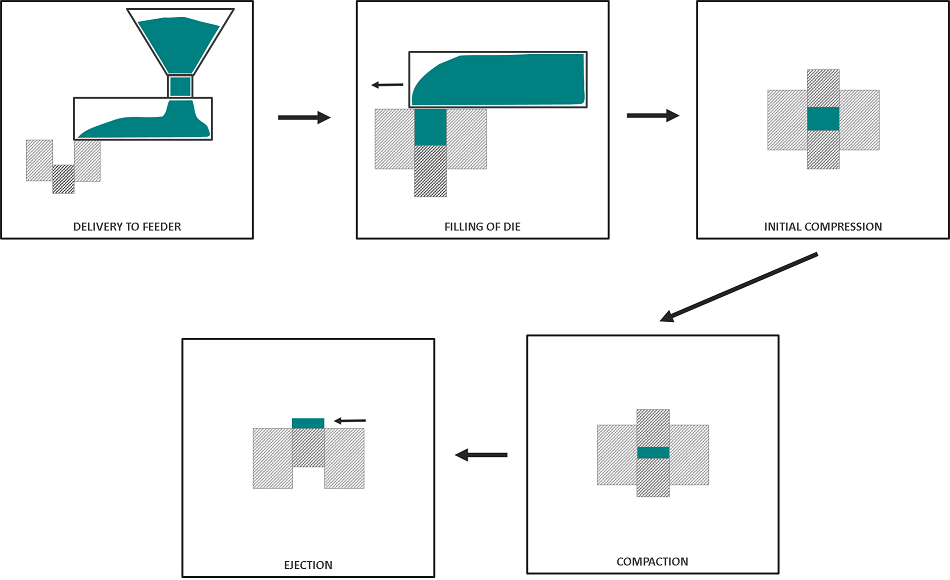

Filling is a common operation across many industries, although fill weights and tolerances vary widely. The properties that influence efficiency will depend on the type of equipment being used, e.g. gravity driven or force-fed as well as factors such as geometry of the feedframe, flow rate through the process and characteristics of the powder. The wide variation in each variable creates a complex challenge.

This application note presents a study where the FT4 Powder Rheometer® is used to evaluate the compatibility of material properties with the conditions imposed in the processing environment.

Please click here to view or download the application note.