Jul 9 2018

Trelleborg Sealing Solutions is set to unveil a pioneering product that could “radically improve the reliability” of rotary wing aircraft.

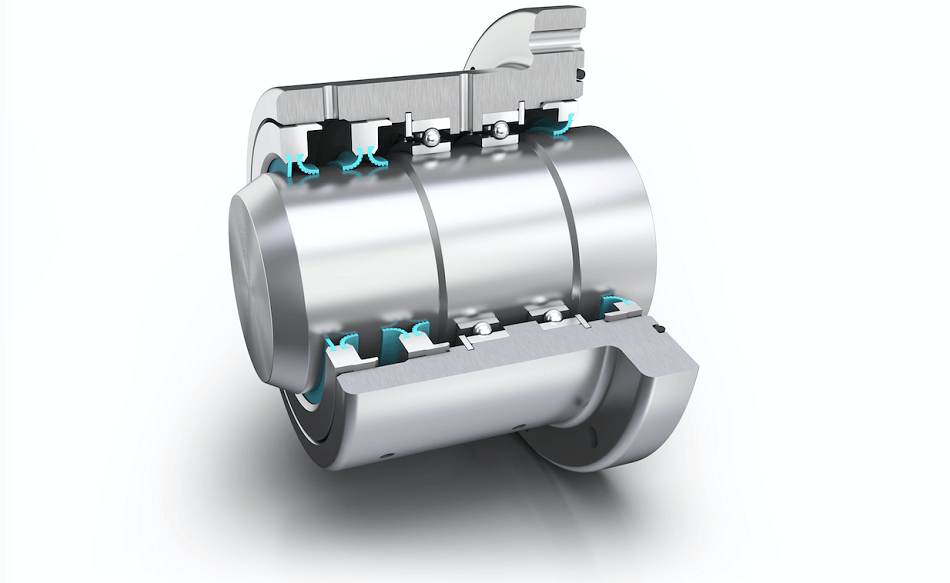

The Turcon® Varilip® PDR RT rotary shaft seal, which has already been proven to out perform other similar seal products, was developed to meet the ever-growing demand to provide seal integrity at increasingly higher rotational wing speeds. The seal is an integral part of the gearbox assembly and is critical to the reliability and performance of the aircraft.

Torben Andersen, Trelleborg Sealing Solutions Director of Aerospace, said: “This project started several years ago, when we wanted to find a seal that would provide a better performance at very high speeds, specifically for rotary wing aircraft.

“We knew that at high surface speeds, ensuring that essential lubrication is maintained was a major challenge and any leakage would compromise the operation of the aircraft. That’s why designing a seal that out performs anything that’s currently out there was so vital.”

During the development of the Turcon® Varilip® PDR RT rotary shaft seal, Trelleborg designed and commissioned bespoke high speed test equipment capable of running at speeds of up to 24,000 rpm and a test programme that closely followed the way rotary wing aircraft gearboxes work. This allowed developers to ensure that the seal met highly demanding application requirements.

During the development of the seal, the team experimented with a number of different lip materials, marrying them to various seal designs and investigating the best lip geometries and lip features to select the correct profile and material.

Torben added: “This is a breakthrough. We’ve developed a process that facilitates a seal with less torque, friction and heat to reduce maintenance; one that will radically improve the reliability and boost the performance of rotary wing aircrafts.

“Though initially designed for this specific application, the work we’ve done shows that it also lends itself to other applications that require high speed rotary performance. We’re already generating interest from designers of electromechanical actuators and from a wide range of other market segments.

“For many years there has been a standard version of the Turcon® Varilip® PDR – but this new seal operates effectively with less power and is therefore more efficient. We’ve optimised the design so it can run on a range of surface finishes and coatings, including ceramics.”

Using Trelleborg’s bespoke testing equipment, the Turcon® Varilip® PDR RT rotary shaft seal has undergone more than 20,000 hours of endurance testing with latest designs operating at 3,500 hours leak free.

Trelleborg Sealing Solutions will be displaying this and other innovations at the Farnborough International Airshow from July 16th – 22nd in Hall 4, Stand 41372.