Oct 26 2018

A critical step change has been accomplished in the manufacturing of MOFs that will significantly advance their commercialisation.

In 2018, a group of EU project partners (ProDIA) have successfully developed synthesis processes enabling the manufacture of metal organic framework (MOFs) materials at an industrial scale. These innovative methods have significantly reduced production costs permitting MOFs to be priced competitively against many current market leading materials. With this ability to offer these advanced porous materials at an economically viable price, the projected benefits from their superior performance can now be realised. This places MOFs perfectly to meet tomorrow’s big challenges in energy, environmental and health application areas.

What is a MOF?

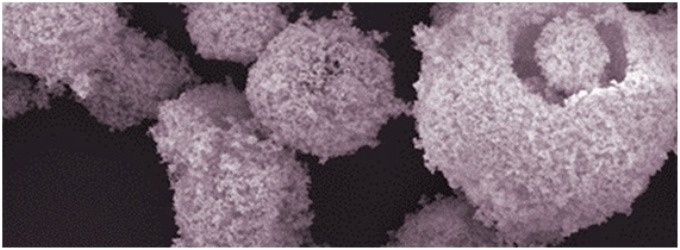

Metal organic frameworks (MOFs) are some of the most exciting materials to have emerged in science in the last two decades. They are powdered solids comprised of metals or metal clusters linked by organic ligands into extended networks, which often have very high porosity in the nanopore range (1 nanometre = 10-9 m). It is these small pores or cavities that make these MOF materials ideally suited for the storage of gases such as CH4, H2O, CO2, NH3 and NO to name but a few. Indeed, coupled with their chemical flexibility it has been shown that MOFs have great potential in a diverse range of sectors covering energy, environmental and biological application areas. To date, the number (several 1000’s) and rate of scientific publications relating to the synthesis, characterisation and application of MOF materials has broken all previous records. The momentum gained in these academic studies however, has not yet been translated to industrial use until now!

Who is ProDIA?

In the framework of the European collaborative research project ProDIA, 12 partners from industry, R&D organisations and universities joined forces with the aim of accelerating the industrialisation of nanoporous materials[1]. Within the three year timescale, the ambitious plan was to link experts in synthesis, shaping and formulation with end application users to create scalable processes that enable manufacture of application ready MOF articles. The ProDIA consortium was awarded 7 million Euros from the EU Horizon 2020 program amounting to a global effort of 760 person months.

What has ProDIA achieved?

The consortium has successfully achieved significant advances in two areas critical to MOF industrialisation/manufacture and shaping/formulation. Several manufacturing processes were explored, developed and validated to enable the multi-kilo scale production of a structurally and chemically diverse range of MOF materials. Suitably shaped bodies and formulations comprising the manufactured MOF powders were fabricated, characterised and tested for use in the key application areas of gas storage for clean mobile energy, waste heat-based cooling solutions for data centres, air purification, and prevention of medical device acquired infections. Data collected in side-by-side testing with industry benchmarks prove the superior performance achievable from the manufactured materials, confirming their immense future potential.

MOFs designed by ICN2

A group of researchers lead by Dr Inhar Imaz and ICREA Prof. Daniel Maspoch at the Catalan Institute of Nanoscience and Nanotechnology (ICN2) are the brains behind one of the methods for MOF synthesis given a boost by the project: spray-drying. A success story within a success story, the ICN2’s spray-drying method was first published in Nature Chemistry in 2013. It was patented and licensed to fellow ProDIA partner MOFApps by 2015. Today, as part of this project, it has been scaled up from gram- to kilo-scale production in collaboration with the research group led by Prof. David Farrusseng (IRCELYON, CNRS), MOFApps and Axel’One. The key to this swift journey from lab to industry is that the method has been adapted from a common industrial process that requires no specialised equipment. It also uses water as the reaction media, making it a low-cost, environmentally friendly route to the continuous production of a range of porous MOFs. Unique in Europe, the proof-of-concept installation located at Axel’One stands 10.5 metres tall and yields several tens of kilos of the copper-based MOF, HKUST-1, in just a few hours. This is an important step towards industrial-scale production (~300kg/day) of MOFs via spray drying, which would give these materials the competitive price point they need for mass uptake.

Prof. S. Kitagawa (Kyoto University), pioneer and most cited MOF researcher, explains: "The ProDIA project is a real success in the innovation field. ICN2, IRCELYION, MOFApps and Axel'One and its scale-up results made a major contribution. Today, the availability of MOFs at the pilot scale makes it possible to foresee their future use in large-scale applications.”

Future Outlook?

Today, with the capability to produce MOFs at the multi-kilo scale it is possible to foresee their future use in large-scale application areas such as data centre cooling, air purification, infection prevention and the storage of natural gas or hydrogen for transportation.

Without any doubt, the fate of MOF is crystalline.

ICN2 patents: Method for the preparation of metal-organic frameworks. EP 11183773.8 link and EP16382120.0 link

Nature Chemistry article:

A. Carné-Sánchez, I. Imaz, M. Cano-Sarabia, D. Maspoch. A spray-drying strategy for synthesis of nanoscale metal-organic frameworks and their assembly into hollow superstructures. Nature Chemistry. Vol. 5, Issue 3, pp. 203-211 (2013). DOI: 10.1038/nchem.1569

[1] ProDIA has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 685727. Partners: CNRS, Institute of Nanoscience and Nanotechnology (ICN2, ES), Axel’One, ENGIE, IFP Energies nouvelles (FR), Fraunhofer IKTS (DE), Johnson Matthey, MOF technologies, University of St Andrews (GB), MOFapps, SINTEF and University of Oslo (NO).