Nov 16 2018

From the wires suspending bridges to the proverbial pots and pans, metal composites have to account for a range of durability, malleability, and strength to fulfill human requirements.

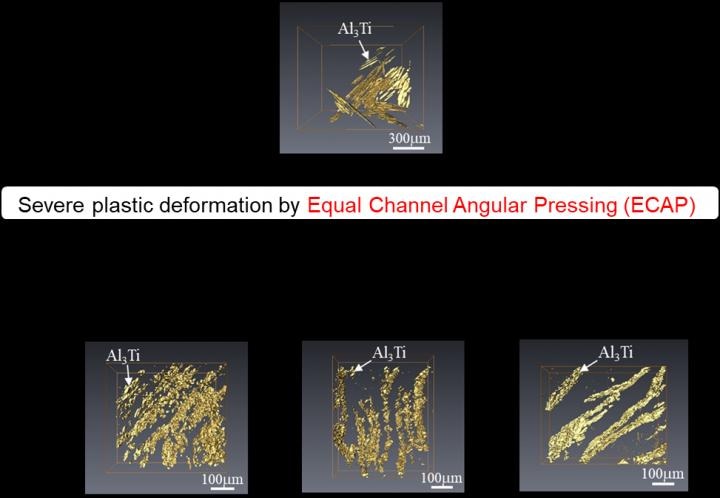

3D images showing spatial distributions of fragmented Al3Ti in Al-Al3Ti specimens before and after Equal Channel Angular Pressing (ECAP). It is shown Al3Ti particles fragments deformed under routes A, Bc, and C with 4 passes have different spatial distribution of the fragmented Al3Ti particles. (Image credit: NITech)

3D images showing spatial distributions of fragmented Al3Ti in Al-Al3Ti specimens before and after Equal Channel Angular Pressing (ECAP). It is shown Al3Ti particles fragments deformed under routes A, Bc, and C with 4 passes have different spatial distribution of the fragmented Al3Ti particles. (Image credit: NITech)

Now, at the Nagoya Institute of Technology (NITech) in Japan, scientists have used three-dimensional (3D) crystallography to view how the composites are shaped up by individual particles and how they can be possibly exploited to make more improved versions of themselves.

Strength of the composite is controlled by size, spatial distribution, and three-dimensional shape of the particles.

Dr Hisashi Sato, Associate Professor, Graduate School of Engineering and Frontier Research Institute for Materials Science, Nagoya Institute of Technology.

Dr Sato teamed up with Professor Yoshimi Watanabe on this study.

During the development of composites, like drawing out metal alloys to create suspension wires for bridges, the materials are stressed and pressed to allow the particles to break apart. These particles are subsequently drawn out into a thinner rearrangement, but here, care must be taken to control them carefully, or else they might lose their strength or become fragile. This process, known as equal channel angular pressing (ECAP), is generally referred to as “deforming” the composite particles from their original state.

Dr Sato informed that none has ever investigated the change in particle distribution through images of the deformed composite in three dimensions. In this regard, 3D microstructural observation and crystallographic analysis were used by Dr Sato and Professor Watanabe to study how the particles altered in placement, size, and shape in aluminum-based composites.

Both discovered that the distorted fragments again distributed on how the scaffolding, or the matrix, that underlies the composite material was first broken apart and then put back together, like particles rearranging closer together while a suspension wire is being drawn out because of the reduced surface area. More significantly, Dr Sato added that one can control the particle distribution in the deformed composite material depending on the material flow of its matrix.

The team also studied the impacts of shearing patterns, or altering the specimen direction for each ECAP pass. In the above figure, Routes A, Bc, and C are the cases of specimen without rotation, with a 90° rotation, and with a 180°degree rotation with four passes, respectively. The duo also discovered that the smallest Al-Al3Ti particle fragment was produced by Route Bc. The Al3Ti inter-metallic particle is believed to preferentially fragment at a particular location in the deformation process, which provides one more level of control to design a better grain.

Earlier, scientists noticed that the deformation process for the Al-Al3Ti composite produced a better grain refiner for the Al casting; however, they failed to comprehend the mechanisms underlying the enhanced outcomes, Dr Sato said. Now, engineers and researchers might be able to create a better grain refiner for Al casting with accurate control.

Strength and ductility of the metal-based composite strongly depend on the particle size and the spatial distribution of the particle. Understanding the relationship between the particle size, the particle spatial distribution, and the mechanical properties of the composite is important in order to design the composite with higher strength and ductility.

Dr Hisashi Sato, Associate Professor, Graduate School of Engineering and Frontier Research Institute for Materials Science, Nagoya Institute of Technology.