Dec 7 2018

Although it would be easy to make bubbles, making countless numbers of them a minute—all with an equal size—would be highly impossible.

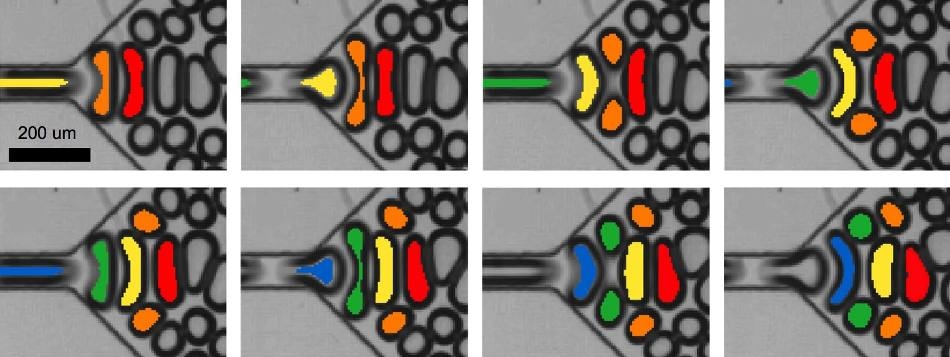

A sequence shows the progression of bidisperse foam generation in a microfluidic device created at Rice University. When bubbles enter, they pinch the preceding bubble into two before becoming a wall against which the next bubble will be pinched. (Image credit: Biswal Lab)

A sequence shows the progression of bidisperse foam generation in a microfluidic device created at Rice University. When bubbles enter, they pinch the preceding bubble into two before becoming a wall against which the next bubble will be pinched. (Image credit: Biswal Lab)

Now, engineers at Rice University have successfully achieved that and much more. Sibani Lisa Biswal, Rice chemical and biomolecular engineer, along with graduate student and lead author Daniel Vecchiolla, has developed a new microfluidic device that can pump out over 15,000 microscopic bubbles per second and can be adjusted to make them in one, two, or three discrete sizes.

Featured on the cover of the Royal Society of Chemistry journal Soft Matter, the study allows “wet”, customizable foams in minute amounts for applications concerned with biological and chemical studies.

The interesting part is that the difficult part is done by bubbles themselves.

A movie demonstrating the mechanism reveals extended bubbles that shoot via a tube into an input channel. Every arrow-like bubble shifts with a force that is sufficient to divide the bubble ahead of it; however, the arrow continues to remain intact. After taking its position between the new “daughter” bubbles, it becomes a “wall” holding the subsequent bubble in place for splitting. In this fashion, only every other bubble that enters the expansion divides from the inter-bubble forces.

Vecchiolla calls this process as “metronomic”—the tick is a bubble splitting and the tock is a bubble that stays intact.

After the input is centered and all the other parameters, such as the nature of the liquid, its viscosity, the channel width, and the flow rate, are correct, the device fills with two ranks of matching, tinier bubbles along the edges and with large bubbles in the center. Offsetting the input allows the stream to create bubbles in three sizes.

There’s interest in using monodisperse bubbles for material applications and miniaturized reactors, so there’s been a lot of studies about the generation of uniformly sized gas bubbles. But there have been very few that looked at using neighboring bubbles to create these daughter bubbles. We’re able to generate well-ordered foam systems and control the size distribution.

Sibani Lisa Biswal, Associate Professor, Chemical and Biomolecular Engineering, Materials Science and Nanoengineering, Rice University

Vidya Giri, a recent alumna, assisted in creating the microfluidic channels, which measure roughly one-twentieth of an inch wide together with a feeder channel of approximately 70 µm.

Biswal is an associate professor of chemical and biomolecular engineering and of materials science and nanoengineering. The study was supported by the National Science Foundation.

Microfluidic foam

A video shot at more than 30,000 frames per second shows how bubbles generated in a microfluidic device “pinch” one another as they create a foam. Rice University engineers made the devices to generate foam with bubbles in two or three distinct sizes. (Video credit: Biswal Lab)