Owing to polymer science, ubiquitous requirements of everyday life like rubber tires, plastic water bottles, Kevlar and Teflon, nylon jackets among many others have been possible. Elastic polymers, called elastomers, can be stretched and released again and again and are used in applications such as heart valves and gloves, where they need to endure for a long time without ripping apart.

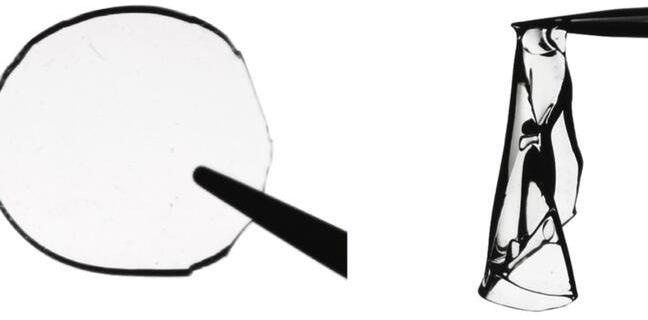

A highly entangled hydrogel (left) and a regular hydrogel (right). Image Credit: Suo Lab/Harvard SEAS.

A highly entangled hydrogel (left) and a regular hydrogel (right). Image Credit: Suo Lab/Harvard SEAS.

But a problem has long baffled polymer researchers: Elastic polymers can either be stiff or can be tough, but they cannot be both.

Scientists have found this stiffness-toughness conflict a big challenge while designing polymers that could be used in several applications such as bioprinting, bioadhesives, tissue regeneration, wearable electronics and soft robots.

In an article published recently in Science, scientists from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have come up with a solution to that long-standing challenge by creating an elastomer that is both tough and stiff.

In addition to developing polymers for emerging applications, scientists are facing an urgent challenge: plastic pollution. The development of biodegradable polymers has once again brought us back to fundamental questions — why are some polymers tough, but others brittle? How do we make polymers resist tearing under repeated stretching?

Zhigang Suo, Study Senior Author and the Allen E. and Marilyn M. Puckett Professor of Mechanics and Materials, SEAS

Polymer chains are created by connecting monomer building blocks together. Polymer chains are cross-linked by covalent bonds to make a material elastic. With more crosslinks, the polymer chains are shorter and the material is stiffer.

As your polymer chains become shorter, the energy you can store in the material becomes less and the material becomes brittle. If you have only a few crosslinks, the chains are longer, and the material is tough but it’s too squishy to be useful.

Junsoo Kim, Study Co-First Author and Graduate Student, SEAS

To make a polymer that is both tough and stiff, the scientists sought physical, instead of chemical bonds to connect the polymer chains. These physical bonds, known as entanglements, have been recognized in the field for nearly as long as polymer science has been present, but they have been believed to only influence stiffness, not toughness.

But the SEAS researchers discovered that with sufficient entanglements, a polymer could become tough without conceding stiffness. To develop extremely entangled polymers, the team used a strong monomer precursor solution with 10 times less water than other polymer recipes.

By crowding all the monomers into this solution with less water and then polymerizing it, we forced them to be entangled, like tangled strings of yarn. Just like with knitted fabrics, the polymers maintain their connection with one another by being physically intertwined.

Guogao Zhang, Study Co-First Author and Postdoctoral Fellow, SEAS

When hundreds of these entanglements are used, just a few chemical crosslinks are necessary to maintain the stability of the polymer.

“As elastomers, these polymers have high toughness, strength, and fatigue resistance,” said Meixuanzi Shi, a visiting scholar at SEAS and study co-author. “When the polymers are submerged in water to become hydrogels, they have low friction and high wear resistance.”

High fatigue resistance and high wear resistance boost the polymers’ durability and lifetime.

“Our research shows that by using entanglements rather than crosslinks, we could decrease the consumption of some plastics by increasing the durability of the materials,” said Zhang.

We hope that this new understanding of polymer structure will expand opportunities for applications and pave the way for more sustainable, long-lasting polymer materials with these exceptional mechanical properties.

Junsoo Kim, Study Co-First Author and Graduate Student, SEAS

Harvard’s Office of Technology Development has protected the intellectual property related to this project and is seeking commercialization options.

This study received support in part from Harvard MRSEC under grant number DMR-2011754.

Journal Reference:

Kim, J., et al. (2021) Fracture, fatigue, and friction of polymers in which entanglements greatly outnumber cross-links. Science. doi.org/10.1126/science.abg6320.