These broken or fractured bones must be supported and stabilized until they regain sufficient strength to be used again. Casts and splints were historically used to provide this stability, but improved sterile procedures have enabled fractured bones to be set using internal implants such as plates, screws, or rods.

Internal fixation offers a number of benefits to patients, including reduced hospital stay, faster healing, and reduced chances that the broken bone will heal incorrectly or in the wrong position.

These internal fixation implants are typically made from steel, titanium, chrome, or cobalt.

Despite these advances, there remains a risk of infection or rejection after implants have been inserted to help stabilize broken or fractured bones. These infections can lead to the need for further operations, or even limb loss or death in the worst-case scenario.

The administration of antibiotics can help reduce these infection risks, but it has been historically challenging to ensure that these reach the implant site in a sufficiently targeted manner when using oral or intravenous antibiotics alone.

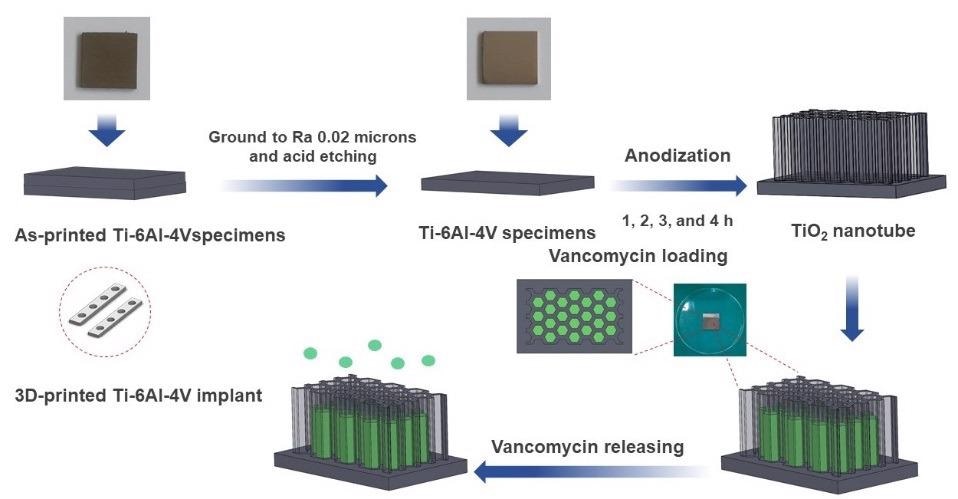

A schematic diagram depicting a stage-by-stage the vancomycin release protocol from the fabricated titania nanotubes surface on the 3D-printed Ti-6Al-4V implant material. The as printed specimen was ground and chemically etched to a suitable roughness surface. The titanium nanotubes (TNTs) were synthesized at different at anodization duration. mage Credit: Chunate, H et al., Materials

More localized drug delivery approaches such as antibiotic loading bone cement offer a better targeted option, but there have been issues around this method’s capacity to release antibiotics at sufficient and sustained levels.

A recent study in the Materials journal outlines the excellent potential of titania nanotubes (TNTs).

These TNTs could be incorporated into the surface of customized, 3D printed implants that have been specifically developed to accommodate patients’ particular fractures.

Studies investigating the use of TiO2 nanotubes that had been coated on a range of biomedical implant surfaces revealed these to exhibit excellent biocompatibility with good potential for cell adhesion and proliferation.

Not only did these TNTs help reduce the risk of implant rejection, but they also offered a promising means of incorporating specific antibiotic drugs directly into the nanotubes, allowing these to be released at the target site in a controlled fashion.

In order to refine and optimize this process, the study used an anodization technique to synthesize arrays of titania nanotubes on a 3D-printed implant surface. The antibacterial drug vancomycin was then loaded into these TNTs and its release performance was analyzed over a 24-hour period.

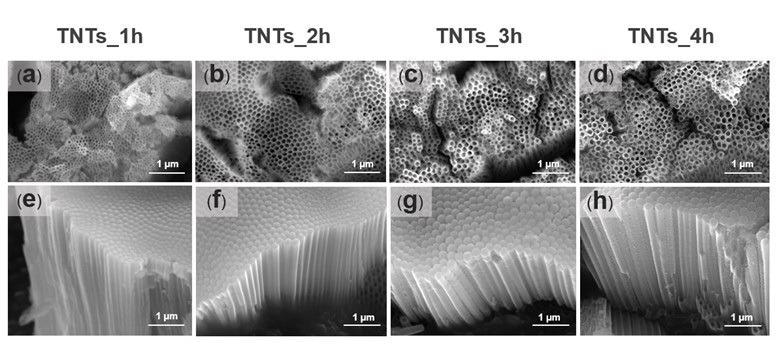

The FESEM micrographs showing the top and side morphological views of the titanium oxide nanotubes fabricated at 1 h (a,e), 2 h (b,f), 3 h (c,g) and 4 h (d,h). The morphology images depict the TNTs orientation and the size of the pores. The pores diameter of the nanotube increased with increase in the anodization time while the length decreased. mage Credit: Chunate, H et al., Materials

The implant itself was comprised of a Ti-6Al-4V plate implant that had been designed and modeled using specialized software prior to being fabricated.

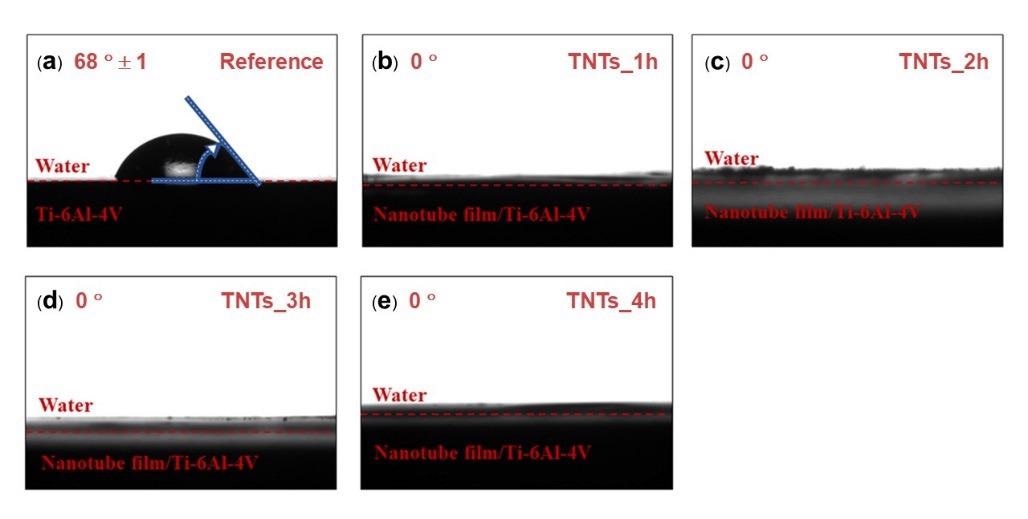

The researchers used a number of high-end characterization techniques including field emission scanning electron microscopy (FESEM), contact angle meter, Fourier transform infrared (FTIR), and an atomic force microscope (AFM) in order to comprehensively investigate the TNTs’ morphology, wettability behavior, functional group and surface topography.

The results of this investigation confirmed that the TNTs were able to effectively act as a reservoir for local drug delivery when these were incorporated into the surface of the 3D-printed implant.

It was found that by controlling parameters such as electrolyte composition, voltage, atmospheric temperature, and anodization time it was possible to optimize the TNTs to enhance the vancomycin release, likely increasing its effectiveness and helping minimize the risks of infection in the vital 24-hour period after insertion of the implant.

These exciting findings offer excellent potential for helping to minimize infection and improve healing of fractures treated with 3D-printed implants. The rough, nanostructured, nanoporous nature of the TiO2 on the implant’s surface is key to ensuring improved implant biocompatibility and osteointegration, with drug-loading offering a robust, targeted alternative to the oral or intravenous administration of antibiotics.

Not only will this have a significant impact on patient health, healing and overall wellbeing, there could also be a notable economic advantage to improving the success rates of bone fixation implants and reducing risks of infection.

Water contact angle of (a) as-printed Ti-6Al-4V, (b) TNTs_1h, (c) TNTs_2h, (d) TNTs_3h and (e) TNTs_4h. The wetting angle of “0” degrees were found in all nanotube surfaces, suggesting the high hydrophilicity of the fabricated TNTs surface. Image Credit: Chunate, H et al., Materials

With the treatment of orthopedic infection and the costs of additional implant surgeries reaching more than $1.6 billion USD in 2020 alone, the potential to reduce the risk of infection relating to implants could substantially reduce burdens on an already hard-pressed global healthcare system.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Sources:

Chunate, H-thaichnok, Jirapon Khamwannah, Abdul A.A. Aliyu, Saran Tantavisut, Chedtha Puncreobutr, Atchara Khamkongkaeo, Chiraporn Tongyam, Krittima Tumkhanon, Thanawat Phetrattanarangsi, Theerapat Chanamuangkon, Torlarp Sitthiwanit, Dechawut Decha-umphai, Pharanroj Pongjirawish, and Boonrat Lohwongwatana. 2021. "Titania Nanotube Architectures Synthesized on 3D-Printed Ti-6Al-4V Implant and Assessing Vancomycin Release Protocols" Materials 14, no. 21: 6576. https://www.mdpi.com/1996-1944/14/21/6576

Lowe, Jason, 2019, American Academy of Orthopaedic Surgeons, Internal Fixation for Fractures. https://orthoinfo.aaos.org/en/treatment/internal-fixation-for-fractures/