Fossil fuel sources in power plants represent a significant barrier to tackling the climate emergency, and while the need to reduce carbon emissions is globally recognized, this remains at odds with increasing energy demands and a growing human population.

Renewable energy sources continue to develop in terms of their efficiency, applicability, and use, but it is anticipated that fossil fuel sources will continue to be used – at least in the short term – to meet global energy demands.

With this in mind, there has been considerable research undertaken into the implementation of carbon capture and storage technologies into existing fossil fuel power plants, in order to limit their emission of carbon dioxide into the atmosphere.

Current methods of carbon capture involve the integration of oxy-fuel, precombustion of post-combustion capture technologies. Oxy-fuel and precombustion methods offer improved energy efficiencies for power plants, but post-combustion technologies represent an easier approach in terms of their integration into existing plants.

The authors believe that Molten Carbonate Fuel Cells (MCFC) could act as a suitable technology in the capture of carbon dioxide from flue gases. The research is based on a number of existing works which look at the potential of MCFC.

Perhaps most notably, MCFC offers the potential to capture carbon dioxide emissions while also producing useful power. Studies have also shown that the integration of MCFC in natural gas combined-cycle power plants can help reduce costs versus other carbon capture methods.

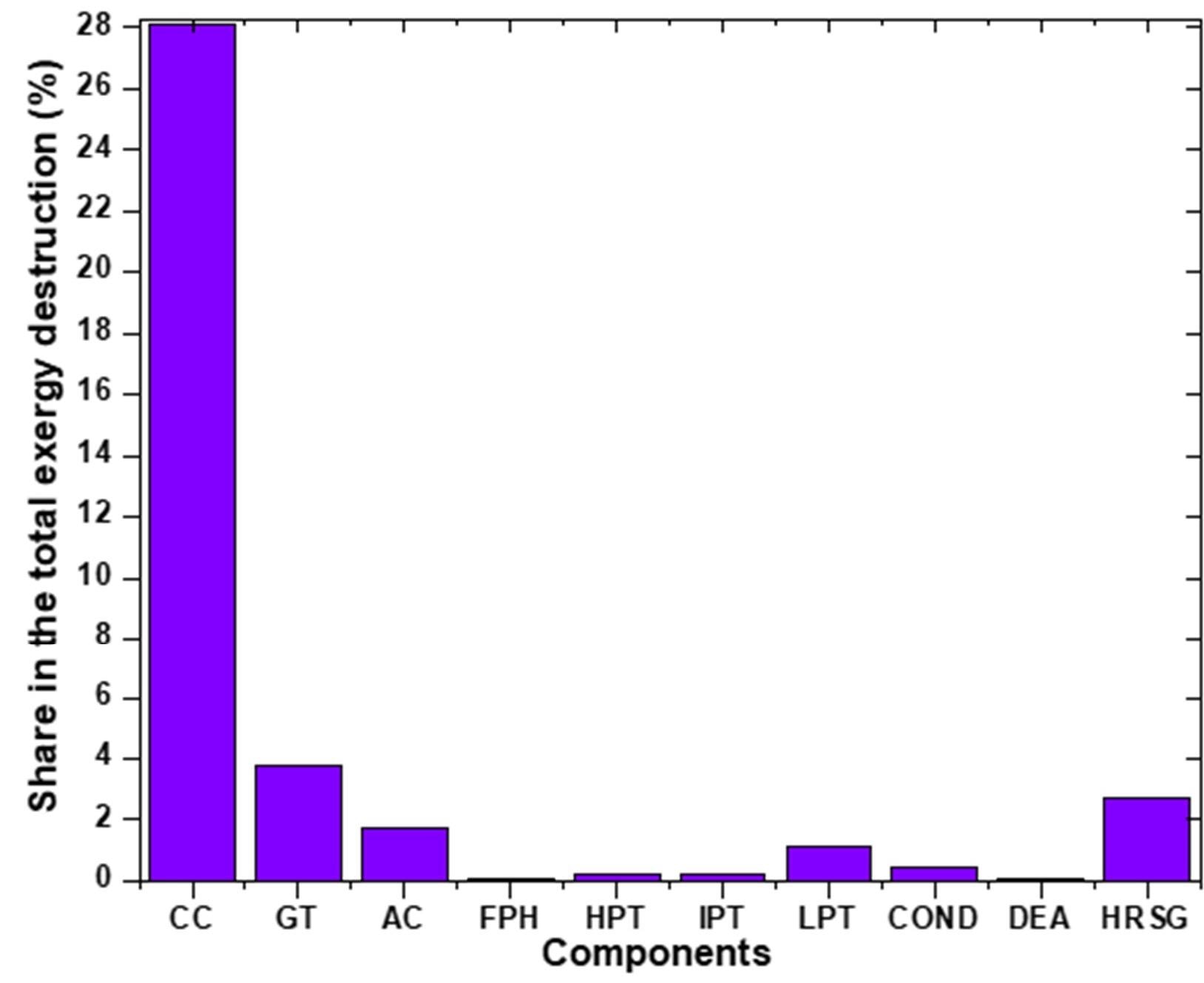

Components in total exergy destruction of the existing natural gas-fired combined-cycle power plant. Image Credit: Fichera, A et al., Sustainability

In order to evaluate this, they created a model whereby this technology would be implemented in the gas turbine of a specific natural gas-fired power plant in Italy.

The reference plant operated with a single gas turbine unit. Exhaust gases from this gas turbine are divided equally into two comparable three pressure level heat recovery steam generators which have been connected with one reheat-regenerative steam Rankine cycle per generator.

The revised model plant functioned in a relatively identical manner to the reference plant, except that the exhaust gas from the heat recovery steam generator unit is passed to the MCFC to facilitate carbon capture.

Flue gas from the HRSG is preheated in a flue gas preheater to ensure this is maintained at the working temperature of the MCFC. This is done using waste heat from the off-gas of the MCFC unit.

The authors conducted a thermodynamic analysis at an estimation of exergy (entropy-free energy) available on the existing plant to look at its performance in terms of efficiency, total power output, and carbon dioxide emissions.

They used the Cycle Tempo software package to undertake energy and exergy analyses of the repowered scheme before comparing both the existing and the proposed plant in terms of their energetic, exergetic, and environmental capabilities.

The proposed repowered power plant was estimated to be able to produce 787.454 MW of power - 435.29 MW via the gas turbine, 248.9 MW via the steam cycle, and 135.283 MW via the MCFC.

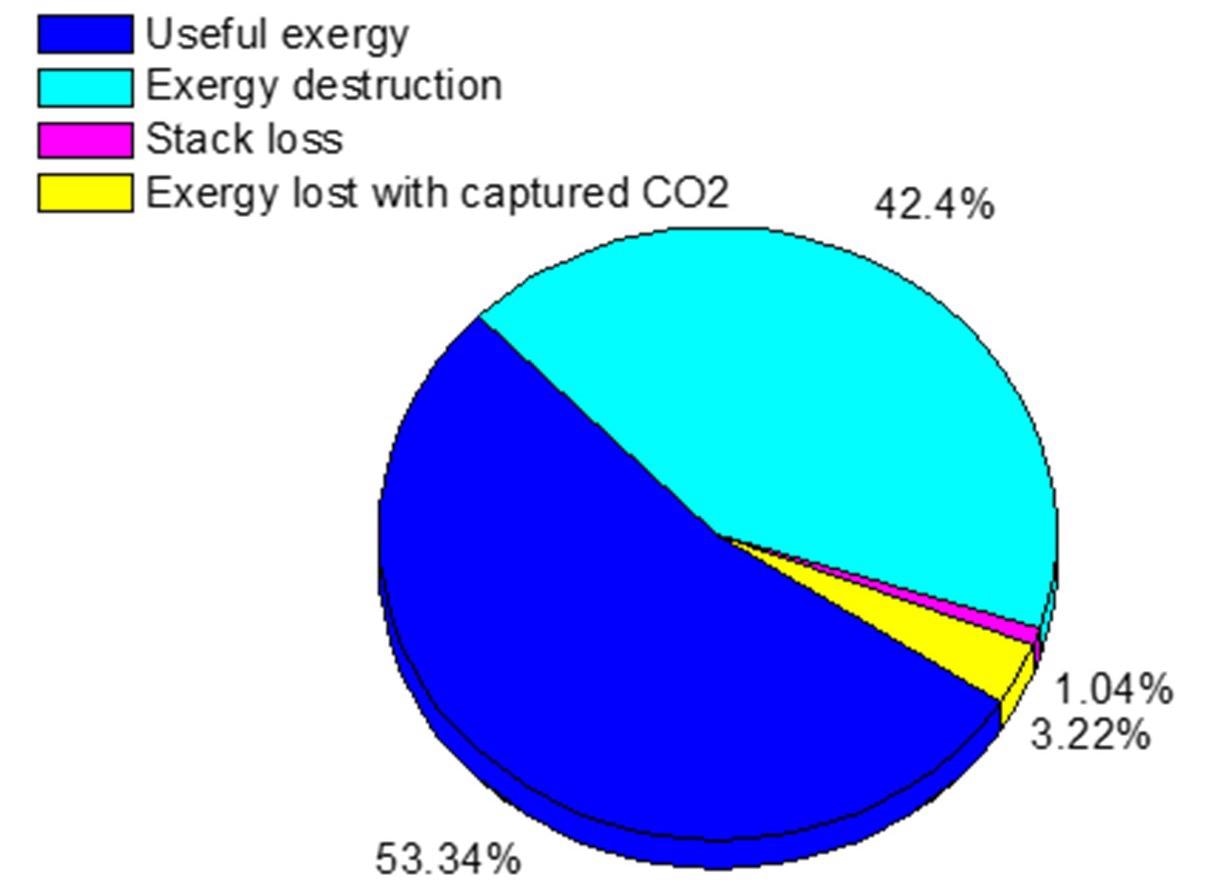

It was noted that the modeled plant obtain 42.4% exergy destruction, most of which took place in the combustion chamber. The net plant efficiency and net exergy efficiency were estimated to be approximately 55.34% and 53.34%, respectively.

Exergy due to the stack loss was reduced versus the initial configuration, and the exergy loss related to the capture system was found to be 3.22%.

The modeled plant’s specific carbon dioxide emissions were found to be approximately 66.67 kg/MWh with around 2 million tons of carbon dioxide sequestrated.

Distribution of total input exergy of the modified combined-cycle power plant with carbon capture. Image Credit: Fichera, A et al., Sustainability

Carbon capture technology represents a useful means of mitigating some of the environmental impacts of fossil-fuel-powered power stations until renewable sources and related technologies are able to meet global energy demands.

Key to their successful implementation will be their ease of installation in existing power plants and their ability to efficiently minimize the plants’ carbon dioxide emissions.

References

Fichera, Alberto, Samiran Samanta, and Rosaria Volpe. 2022. "Exergetic Analysis of a Natural Gas Combined-Cycle Power Plant with a Molten Carbonate Fuel Cell for Carbon Capture" Sustainability 14, no. 1: 533. https://www.mdpi.com/2071-1050/14/1/533

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.