Diamond crystals of different sizes, surface orientations, and nitrogen contents were cut along several crystal planes viz. (100), (110), and (111) using a 532 nm wavelength laser, and the induced magnetic moments were measured with a superconducting quantum interference device (SQUID) magnetometer.

The crystal plane of (100) demonstrated the highest ferromagnetic response owing to the disordered graphite layer, which vanished after moderate temperature annealing and chemical etching.

Magnetism in Diamond

Carbon-based materials such as graphite have shown induced magnetic order on their deformed surface at room temperature with or without doping. The defect-induced magnetism (DIM) due to the presence of ferromagnetic hysteresis in boron-doped, hydrogen ion (H+)-doped, and irradiation-implanted nitrogen (15N) and carbon (12C)-doped diamond nanograins at room temperature is also known.

Additionally, based on the energy and number of pulses, lasers also facilitate the formation of a mixture of sp2–sp3 bonds, which result in a magnetic state in the nanostructure of the diamond.

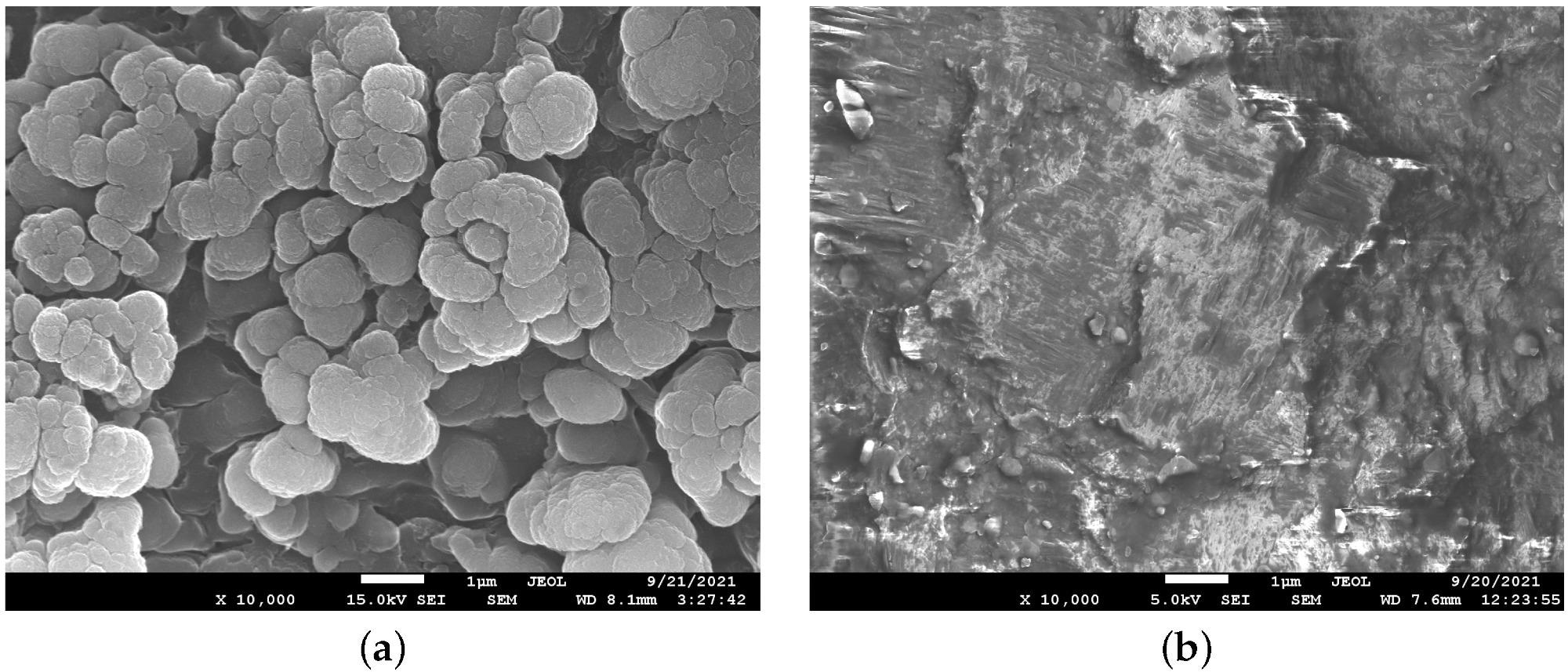

Scanning electron microscope images of the surface of a CVD diamond sample after laser cut (a) and after laser polishing (b). Image Credit: Setzer, A et al., Materials

Furthermore, the heating of the diamond using high-intensity laser radiation leads to graphitization and corresponding lattice defects. Thus, even without the use of any magnetic material, the valence band of the graphite or graphitized diamond surface can be strongly spin-polarized. This also polarizes their rarely occupied conduction band due to a narrow bandgap between the valence band and conduction band of the graphite.

About the Study

In this study, after gluing to the base of a mandrel the researchers cut 6 CVD and 5 natural diamonds along different crystal planes using a pulse laser beam of 532 nm wavelength and 0.5 mJ energy. These crystal planes were (100), (110), and (111).

The material removal volume was fixed by selecting the power, wavelength, and duration of the pulse laser. After cutting the desired surfaces, the graphitic layer was removed by a chemical etching, in which samples were immersed in a solution of concentrated sulfuric acid (H2SO4), fuming nitric acid (HNO3), and perchloric acid (HClO4) followed by heating at 120 ℃ for 4 hours.

Particle-induced X-ray emission (PIXE) with protons was used for the quantitative characterization of the magnetic impurities viz. Fe, Co, and Ni. Subsequently, magnetic moments of all cut samples were measured using a SQUID magnetometer. Finally, temperature hysteresis and magnetic field loops were measured after demagnetizing all samples at 380 K using the above-mentioned method.

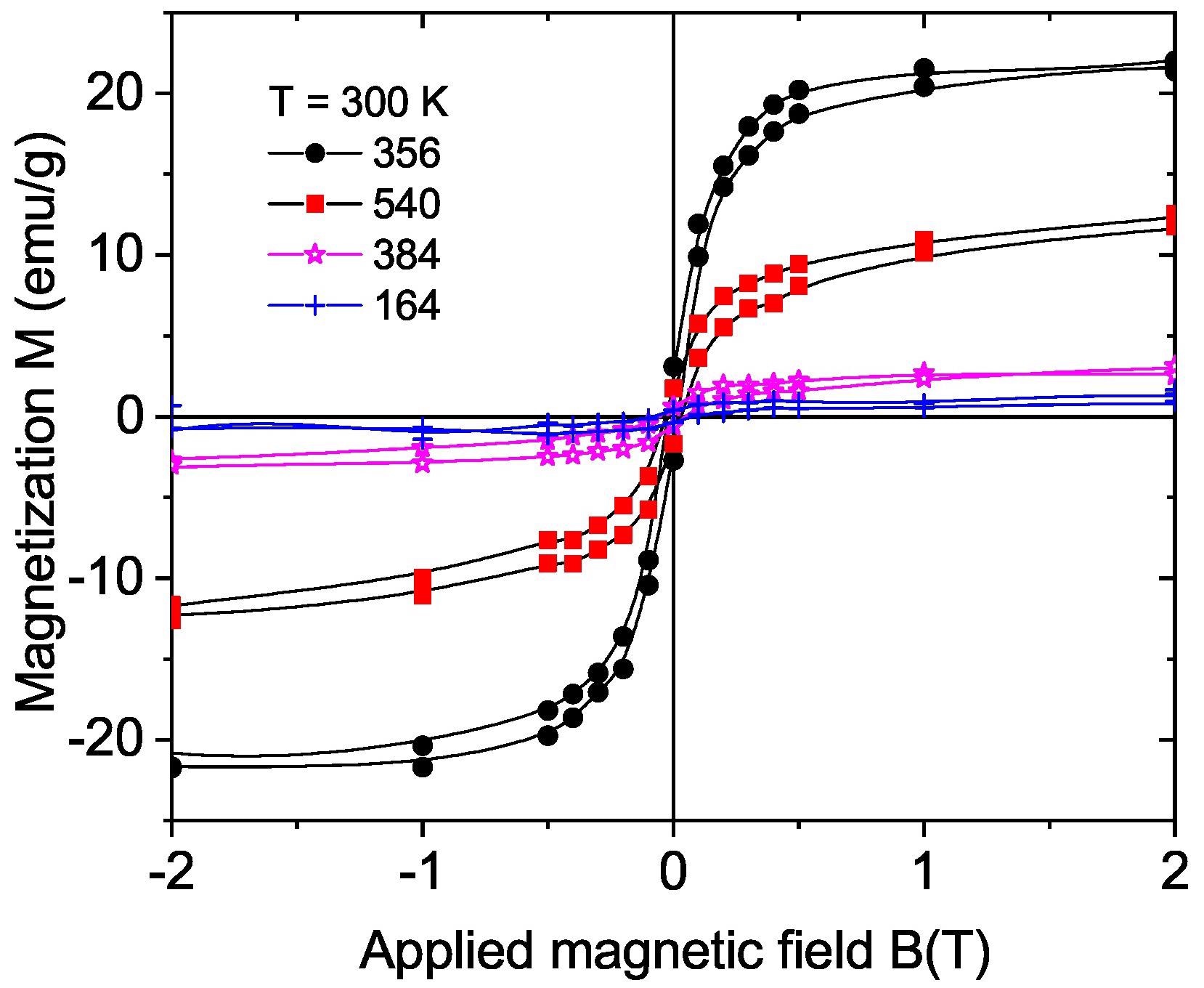

Field hysteresis loops at 300 K of four natural diamond samples ((100) surface, samples 356 and 540; (111) surface, samples 164 and 384). The magnetization values were calculated assuming a ferromagnetic mass given by a 20 nm thick region at the cut surfaces of the samples. Image Credit: Setzer, A et al., Materials

Observations

PIXE results showed that the (111) plane of the 4th natural diamond (#164) had Fe as the highest magnetic impurity concentration of 2.6 ppm, whereas the (111) plane of the 5th natural diamond (#354) had the largest magnetization at saturation, even though the total concentration of magnetic impurities was below 0.5 ppm. Hence, the concentration of magnetic impurities had no significant effect on the amount of magnetization.

The Raman spectroscopy plot of all cut samples showed a sharp characteristic absorption peak of the pure diamond at 1332 cm-1 and distorted graphite peaks at 1580 cm-1 and 1350 cm-1 for the G and D band, respectively.

The SQUID magnetometer did not detect any magnetization for the pure diamond at 300 K. For natural diamond samples, the (100) crystal plane exhibited the highest ferromagnetic hysteresis followed by (110) and (111) planes. (111) crystal plane exhibited almost zero ferromagnetic response due to the disordered graphite layer. Hence, both the laser cut direction and crystalline structure affected the ferromagnetic order in the graphitic-like surface layer.

Furthermore, all samples showed a sharp decrease in the ferromagnetic signal after annealing and chemical etching. The Curie temperature of (100) crystal planes of all samples was higher than 380 K.

![Magnetic properties of sample #1b: (a) Field hysteresis loops at 300 K in the as-received state and after the high-temperature annealing. (b) Temperature dependence of the relative difference 100[mFC(T)-mZFC(T)] / | mZFC(T) | at a field of 0.02 T, before and after annealing.](https://www.azom.com/images/news/ImageForNews_58077_16437155664242366.jpg)

Magnetic properties of sample #1b: (a) Field hysteresis loops at 300 K in the as-received state and after the high-temperature annealing. (b) Temperature dependence of the relative difference 100[mFC(T)−mZFC(T)] / | mZFC(T) | at a field of 0.02 T, before and after annealing. Image Credit: Setzer, A et al., Materials

Conclusions

To conclude, the focus of this study was to analyze the cause of induced magnetization on the laser-cut surface of diamonds. A variety of natural and CVD diamonds with varying concentrations of nitrogen and magnetic impurities were analyzed for three primary crystal planes viz. (100), (110), and (111).

The amount of magnetization was particularly high for the (100) plane. Moreover, the number of magnetic impurities had a negligible impact on the ferromagnetic response. This is mostly due to the distorted graphite layer along the (100) crystal plane.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Setzer, A., Esquinazi, P., Buga, S., Georgieva, M., Reinert, T., Venus, T., Estrela-Lopis, I., Ivashenko, A., Bondarenko, M., Böhlmann, W., Meijer, J. Nanometers-Thick Ferromagnetic Surface Produced by Laser Cutting of Diamond. Materials, 2022, 15, 1014. https://www.mdpi.com/1996-1944/15/3/1014