Fresh fruit is an essential part of a healthy diet, providing several essential vitamins and minerals. However, post-harvest, the quality of soft fruits such as strawberries in particular can become degraded very quickly. Fast softening and decomposition present issues with storage and consumption. Fungal infections of strawberries frequently occur during storage, and their fragile tissues make post-harvesting handling challenging.

Transportation and storage can affect the quality of soft fruits due to physical damage and physiological processes. Loss of nutrients, water, color, and changes in texture can occur which make the fruit unappealing and can lead to lower sale prices and volumes, and consequently economic loss for growers, manufacturers, and retailers.

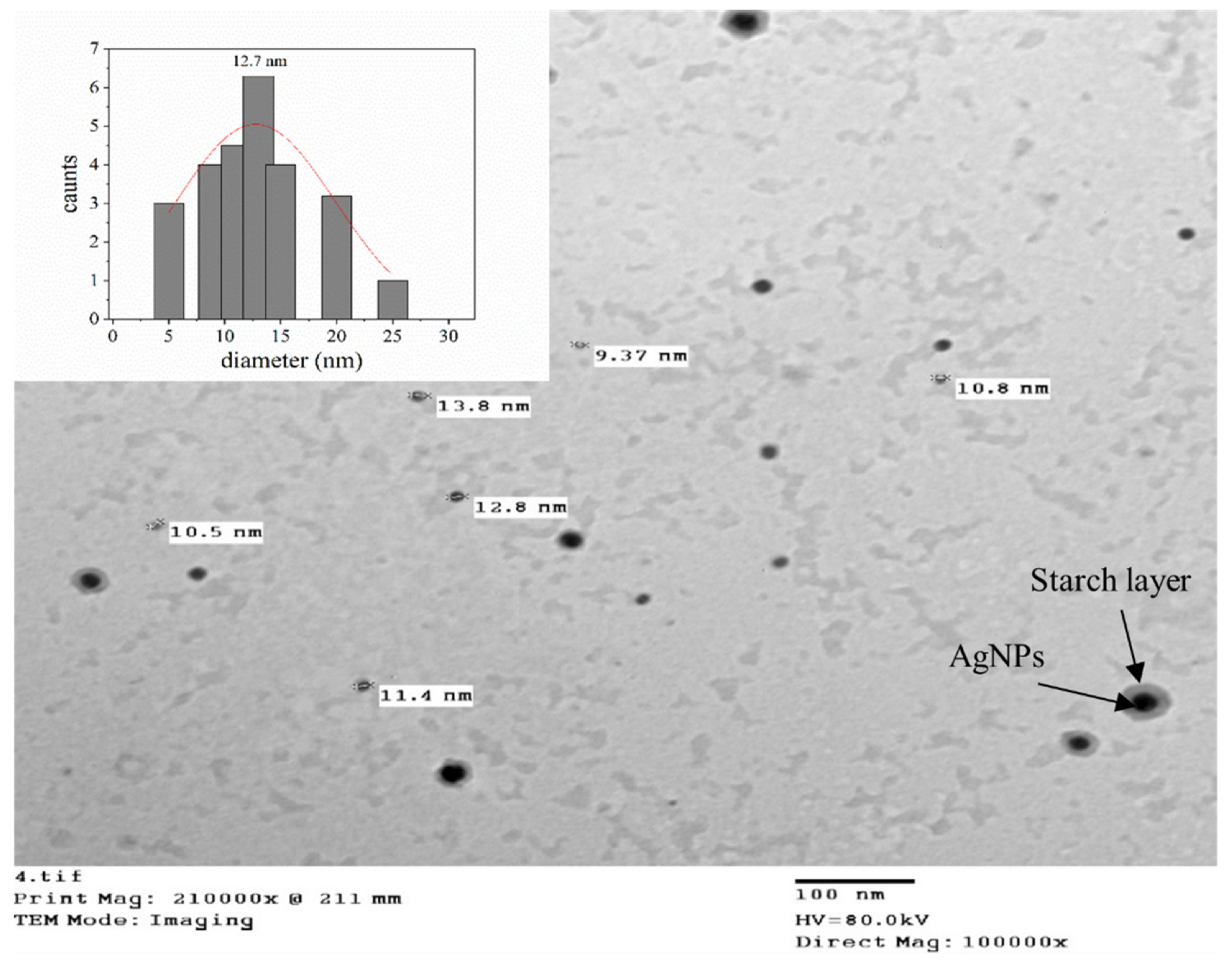

Particle size, shape, and distribution of starch-silver nanoparticles examined using TEM. Image Credit: Taha, I.M et al., Polymers

Strategies for Improving the Quality of Delicate Fruits

Several strategies can be employed to retain the quality and nutritional profile of delicate foodstuffs, including rapid freezing methods. Another method that can be employed is coating the surface of the fruits with various biodegradable and non-toxic substances to protect them against environmental factors.

A biodegradable polymer, starch is found in plants. This polysaccharide is non-toxic, cheap, and abundant, making it an ideal material for coating fruit. However, due to its limited flexibility and brittleness, processing starch can be challenging.

In recent research, the addition of nanoparticles to coatings has been explored to improve their properties. Their ability to protect against microbial activity has been established by numerous studies. These nanoparticles can be prepared using both physical and chemical methods and for many decades now, silver nanoparticles have been used as food additives and materials which are used for food contact.

Uses of silver-nanoparticle containing food coloring include chocolate and confectionery coatings and liqueur additives. In some countries, however, using silver directly or in food contact materials is restricted or forbidden. The EU, for example, has classified it as a suspicious additive. The US’s FDA, on the other hand, has allowed its use.

In recent years, several novel applications have been explored using silver nanoparticles. They have been proposed as an alternative to sulfur dioxide because of the health risks from sulfides, or to augment the antimicrobial properties of this substance. Silver nanoparticles have also been investigated as functional ingredients to provide anti-caking properties and for clarifying liquids. Several studies have investigated how silver nanoparticles can improve the quality and shelf-life of foods.

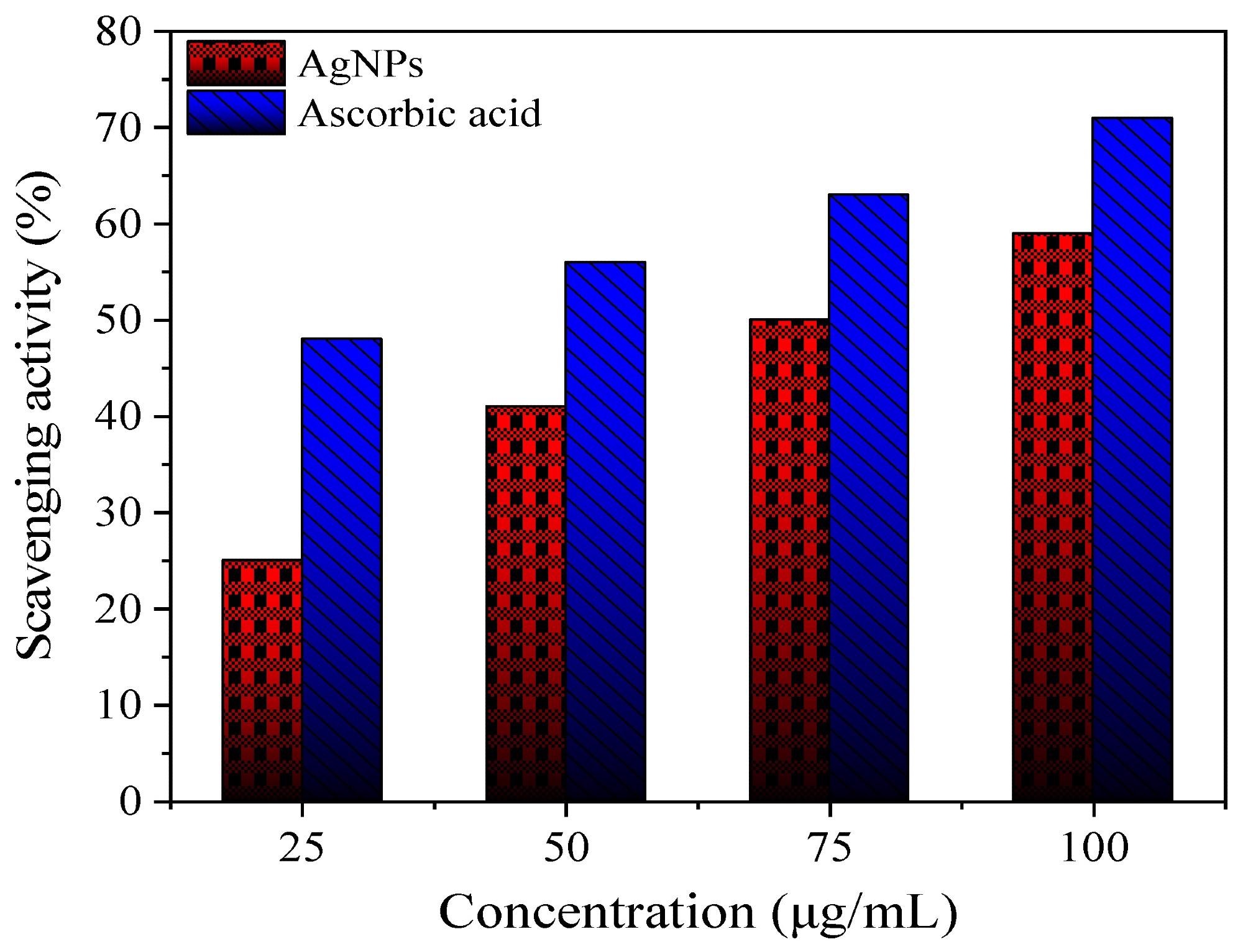

DPPH free radical scavenging activity (%) of St-AgNPs compared to ascorbic acid. Image Credit: Taha, I.M et al., Polymers

The Study

The paper published in Polymers has used strawberries as a food model to investigate how coating fruit with nanoparticles can help to improve their quality and shelf-life. The differences in shelf-life of untreated and treated strawberries were examined, along with the differences in physical, microbiological, and chemical properties. The authors synthesized and characterized several silver nanoparticles in the study.

Nanoparticle coatings were prepared from a solution of starch and silver nitrate. Ethanol was used to precipitate nanoparticles, with this precipitate washed to remove by-products and unreacted components and then separated, dried, and characterized. Characterization methods used in the research were TEM, FTIR, and UV-Visible analysis, and additionally, antioxidant activity was characterized by the authors and compared to ascorbic acid.

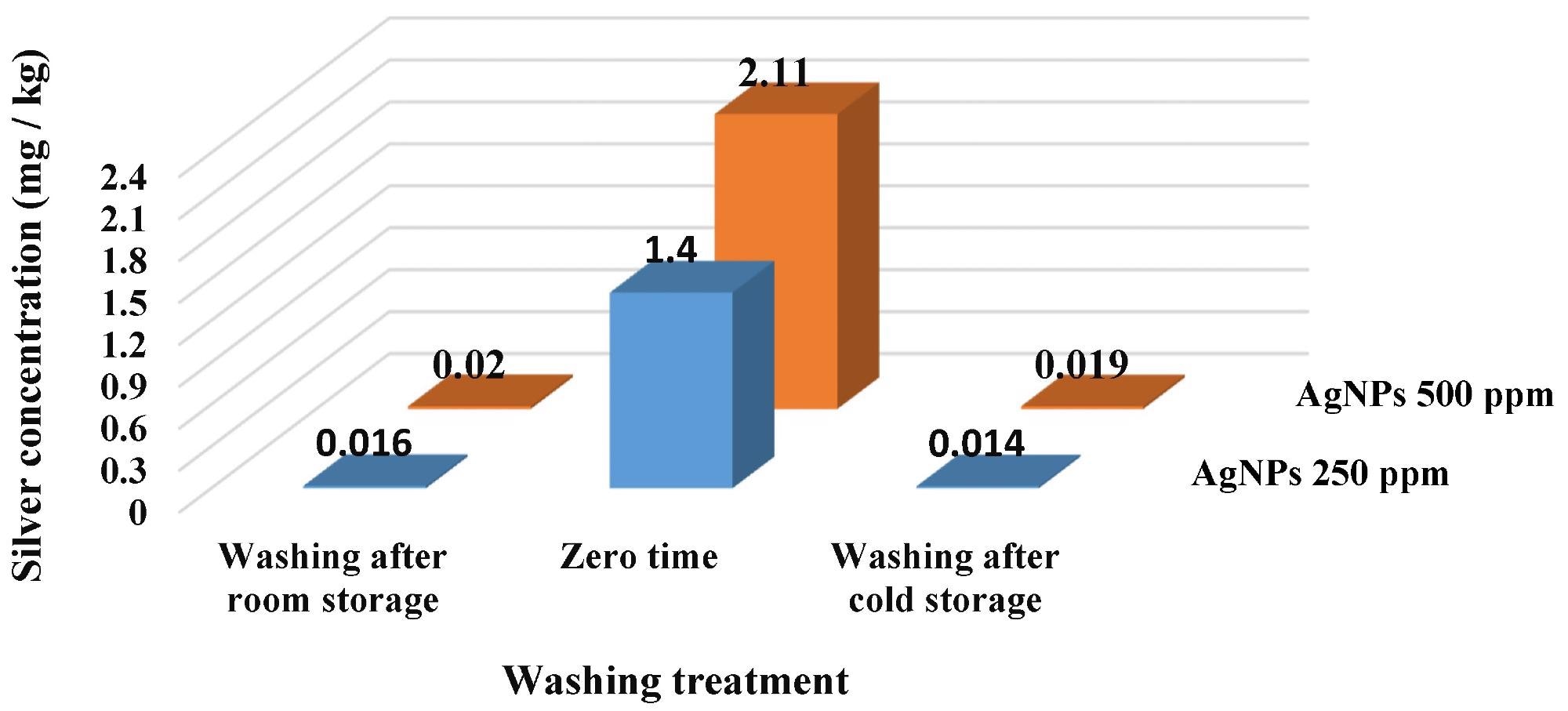

Analysis of the effect of the washing process on silver removal by the inductively coupled plasma-optical emission spectrometer (ICP-OES). Image Credit: Taha, I.M et al., Polymers

Fruits were selected based on being the same size and having a lack of damage and fungal infection. They were then coated with the novel nanoparticles, and glycerol was used as a plasticizer. A soaking method was used to coat the sample fruit. Samples were then stored in both ambient temperature and refrigerated conditions. The room ambient temperature-stored samples were tested every two days, with the refrigerated samples tested every four days until spoilage occurred in the fruits.

Quality criteria were assessed, including loss of weight, soluble solids content, visual decay, anthocyanin content, and microbial counts. The number of days where they remained marketable was used to assess the shelf-life of the nanoparticle-coated strawberries. Some results of the analyses in the study indicated good antioxidant activity, reduction in weight loss in the coated samples, a lower proportion of visual deterioration, decreased microbial activity, and significantly increased shelf-life of coated strawberries. The effect of washing was also investigated.

The novel coating process provides significant advantages for the post-harvest processing and storage of delicate fruits such as strawberries, and is a low-cost, simple, quick, non-toxic, and environmentally safe strategy. The authors have stated that this technology should be encouraged for use in food processing and packaging.

Further Reading

Taha, I.M et al. (2022) Impact of Starch Coating Embedded with Silver Nanoparticles on Strawberry Storage Time [online] Polymers 14(7) 1439 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/7/1439

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.